Built to Last? How Water Affects Building Materials

Grade 11

Presentation

Hypothesis

Problem

Testable Question: How do different building materials react to water exposure?

Flooding is a recurring natural disaster that causes severe damage to buildings and infrastructure. Past floods in Calgary have shown the vulnerability of structures to water exposure. Different building materials react differently when exposed to water, affecting their durability and long-term performance. Understanding how materials withstand water can help in making better choices to reduce damage in flood-prone areas.

Purpose

The purpose of this experiment is to determine how different building materials (brick, concrete, and wood) respond to water exposure. This study aims to identify which material is most resistant to water damage.

Hypothesis

I hypothesize that if different building materials are submerged in water, concrete will absorb the least amount of water, brick will remain the most durable after exposure, and wood will absorb the most water and deteriorate the most.

Reasoning:

- Brick is dense and moderately porous, making it more resistant to water absorption

- Concrete is highly durable but also absorbs water over time due to its porous nature

- Wood is highly absorbent and can weaken or rot when exposed to water for extended periods

If my hypothesis is correct, concrete would be the most suitable material for construction in flood-prone areas

Research

Introduction

In this experiment, three materials—brick, concrete, and wood—were tested to determine how they respond to water exposure. Initially, plastic was included as a fourth material, however, finding suitable plastic samples for testing was difficult. Based on existing research, plastic materials, such as PVC (Polyvinyl chloride) and acrylic, are highly water resistant and generally do not absorb water like brick, concrete, or wood. While plastic was not tested in this experiment, further studies could explore its long-term durability and performance when exposed to water.

Building Materials

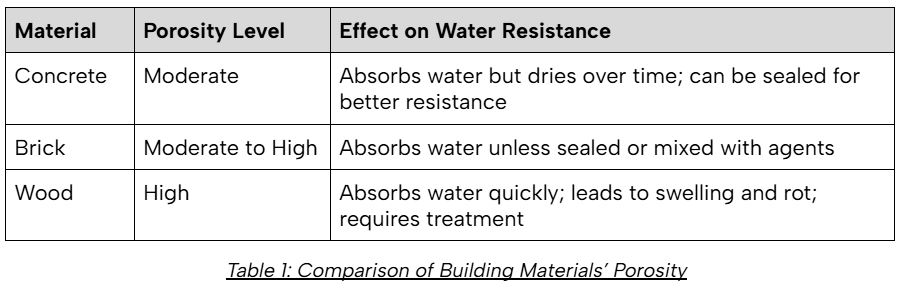

Building materials respond differently when exposed to water depending on their composition, density, and porosity. Understanding these properties helps determine which material is best suited for flood-resistant construction. Historical flooding events have shown how different materials either contribute to or hinder the success of affected structures, which has shaped modern building practices

Brick

Figure 1: Image of a brown and white brick wall. Retrieved from https://unsplash.com/photos/brown-and-white-brick-wall-GN2IqNRlPXs

What is it?

A hard, rectangular building unit made from clay or concrete, typically fired at high temperatures.

Composition

Traditionally made of clay and shale, hardened by heat making it dense and strong.

Properties

- Sustainability: While traditional brick production can require a lot of energy, bricks have a long lifespan and can be recycled, contributing to their sustainability over time.

- Cost: Moderately priced, though specialized costs may increase costs.

- Durability: Bricks are highly durable, offering immense resistance to fire and weathering.

Porosity

Moderately porous, bricks can absorb water but dry out relatively quickly. Certain types of bricks, like clay bricks, absorb more water than engineered bricks. Sealing bricks can reduce water absorption significantly.

Usage

Bricks are typically used to build walls, pavements, and other structures.

Concrete

Figure 2: Image of concrete cubes. Retrieved from https://flic.kr/p/k6vV5S

What is it?

A strong, composite material made by mixing cement, sand, gravel, and water, which hardens through a chemical reaction called hydration.

Composition

Cement (binder), aggregates (sand, gravel), and water, form the basic components. Water-to-cement ratios and additives can affect the strength and porosity of concrete.

Properties

-

Sustainability: Traditional concrete has a high carbon footprint due to cement production, but new developments such as using recycled materials and aggregates is improving its sustainability

- Cost: Varies, but generally cost-effective considering its strength and durability.

- Durability: Concrete is strong and long-lasting, though it is prone to cracking without proper maintenance.

Porosity

Concrete is naturally porous and will absorb water unless treated. The water-to-cement ratio affects porosity, with lower ratios makes it denser and less absorbent concrete.

Usage

Concrete is typically used in foundations, structural frames, pavements, roads, and bridges

Wood

Figure 3: Image of a piles of wood sitting next to each other. Retrieved from https://unsplash.com/photos/a-pile-of-wood-sitting-next-to-each-other-yVRn-d6JGzo

What is it?

A natural material from trees, commonly used in construction and furniture.

Composition

Made of cellulose fibers, giving it both strength and flexibility.

Properties

- Sustainability: Wood is renewable, especially when from managed forests. Using reclaimed or recycled wood enhances eco-friendliness.

- Cost: Generally affordable, with prices varying depending on type and quality.

- Durability: While wood is strong, it is also susceptible to moisture, pests, and fire. Protective treatments can improve its resistance.

Porosity

Wood is highly porous meaning it absorbs water quickly. If untreated, this can lead to swelling, warping, and rot. Generally speaking, softwoods are more porous than hardwoods which are more water resistant.

Usage

Wood is commonly used in residential construction (houses), interior finishes (flooring and decorative finishes), and furniture

Comparison of Porosity

When choosing materials for construction, it is important to consider the specific environmental conditions, structural requirements, and sustainability goals to make the best choice.

Historical Floods and their Impact on Building Materials

Many of the major floods in Calgary have influenced construction practices. For instance, the 1929 Calgary and Southern Alberta Flood, highlighted the vulnerability of wooden structures. After the disaster, discussions about improving flood resilience through better drainage systems and flood-preparedness rose.

The 2013 Calgary Flood, one of the most significant in Canadian history, was a turning point for flood resilience. Despite its durability, concrete still showed signs of water penetration and wooden structures suffered severe water damage, leading to rot and mold. This event resulted in billions of dollars in damage, but also led to changes in building management, such as prioritizing water-resistant materials and elevating structures.

Choosing the Correct Material

When selecting materials for construction, flood-prone areas must prioritize durability and water resistance. The 2013 Calgary Flood demonstrated how crucial it is to use materials that can withstand water exposure. Materials must be chosen not just based on their capabilities in a flood, but also for their sustainability, cost, and availability.

Modern construction practices have moved toward using materials like concrete and treated wood in flood-prone areas, while also incorporating sustainable and waterproof materials such as (recycled) plastic.

Variables

Manipulated Variable (Independent):

The type of building material submerged in water (brick, concrete, or wood)

Responding Variable (Dependent):

The materials’ reaction to water exposure, assessed on qualitative factors:

- Warping or shape changes

- Surface texture differences

- Color changes

- Structural integrity

Controlled Variables (Constant):

- Amount of water used for testing

- Temperature and environment where testing is taking place

- Criteria for observations

- Handling of samples

- Position of samples in water

Procedure

Materials

- Building Material Samples (for 3 trials):

- 3 samples of brick (one for each trial)

- 3 samples of concrete (one for each trial)

- 3 samples of wood (one for each trial)

- Water:

- 4-5 litres of water (enough to fully submerge all the samples)

- Equipment:

- A bucket or container (large enough to hold the water and samples)

- Timer or stopwatch

- Measuring cup (for accurate water measurement)

- Towels (for drying the samples after submersion)

- Gloves and protective clothing (for handling materials safely)

- Camera or smartphone (for documenting changes in the materials)

- Clean surface (to set up your workspace)

- Water disposal area (drain or outdoor space for safe disposal)

Procedure

- Preparation:

- Gather all necessary materials:

- Samples of brick, concrete, and wood

- Bucket or container for water

- Timer or stopwatch

- Towels, gloves, protective clothing

- Camera or smartphone for documentation

- Measuring cup for accurate water volume

- Clean surface for workspace

- Water disposal area (drain or outdoor space)

- Set up the workspace on a clean surface and prepare the area for disposing of used water safely.

- Gather all necessary materials:

- Initial Observations:

- Before submerging any materials, make detailed notes on the physical characteristics of each material (color, texture, surface smoothness, etc.).

- Water Submersion:

- Fill the bucket with 4 litres of water, ensuring there is enough water to completely submerge each material and space around each piece for water flow.

- Carefully place one sample of each material (brick, concrete, and wood) into the water at the same time.

- Observe the immediate reactions of the materials as they make contact with the water (e.g., bubbling, surface texture, color changes).

- Submersion Duration:

- Leave the materials submerged for a set amount of time (adjusted based on your experiment, such as 12 hours or a different duration).

- Ensure that the water level remains consistent and that the samples are undisturbed.

- Post Submersion:

- After the chosen submersion time, carefully remove each material from the water.

- Gently pat each sample dry with a clean towel to remove excess water.

- Record final observations, noting specific changes in size, shape, texture, or color:

- Warping, cracking, or expansion

- Changes in surface texture (e.g., roughness, damage)

- Color changes (e.g., darkening, staining)

- Structural integrity (e.g., crumbling, weakening)

- Take photographs of each material sample to document visual changes.

- Clean Up:

- Safely dispose of the used water in a drain or an outdoor area where it won’t cause harm.

- Clean the testing area to avoid water damage.

- Repeat Testing:

- Repeat steps 4-6 for a total of three trials to ensure consistency in the results.

- Analyze Data:

- Compare the data collected from each material across the three trials.

- Analyze:

- Which material maintained its integrity throughout the trials?

- Which material showed the most significant damage or deterioration?

Observations

The initial observations for all three trials are very similar, with differences being noted in the trial descriptions. To avoid repetition, the pre-submersion observations written in Trial 1 are assumed to be the same for Trials 2 and 3. Each trial used 4 L of water filled into a large water bottle container from a kitchen tap.

Trial 1: Baseline Observations

Brick

- Before submersion: Heavy, light gray, rough edges, visible ridges, some pores.

- During submersion: Pores appeared more visible.

- After submersion:

- Some edges became crumbly, while others remained rough and sharp.

- Small holes and cracks formed on the surface.

- The sample had tiny debris particles in the water.

- Some whitening appeared on the edges and bottom.

Concrete

- Before submersion:

- One side was smooth, the other rough.

- Uneven, with visible rock chunks.

- Powdery residue that stained upon touch.

- During submersion:

- Small bubbles formed on the surface.

- Floating debris particles.

- A darker circular stain appeared.

- After submersion:

- Small holes and openings formed.

- The surface became smoother.

- Initially lost powderiness but regained it after drying.

Wood

- Before submersion: Smooth, minor crack, slight peeling on one side.

- During submersion: Reddish lines appeared on the short side.

- After submersion:

- Strong odor

- Darkened color, rounded softer edges, and increased peeling

- Mass increased from 1284 g to 1555 g (water absorption: 271 g).

Trial 2: Surface Roughness Effect

Each sample was “roughened” with an ‘X’ mark on the flat surfaces to test if surface texture influences water absorption. After submersion, the water level appeared lower, suggesting more absorption.

Brick

- More porous appearance, with increased holes and cracks.

- Cross marks seemed to have intensified water absorption.

- Whitening at the bottom was more pronounced.

Concrete

- After drying, the surface looked darker with more visible holes.

- The cross marks seemed to have allowed deeper water penetration.

Wood

- A bright white area appeared, initially thought to be mold but was later determined to be the beige layer peeling off.

- A small black hole with two inner circles was present, likely allowing more water in.

- Peeling intensified, revealing a carpet-like texture underneath.

Trial 3: Shortened Submersion Time

This trial had a much shorter submersion period to test if exposure duration affected water absorption. The water in this trial appeared dirtier, with noticeable layering and multiple small bubbles.

Brick

- Larger than previous samples (almost double the size), which may have influenced results.

- Heavy and had ridges and bumps.

- Bubbles formed immediately upon submersion.

- After submersion: retained sharp edges, slight whitening at the bottom.

Concrete

- Less powdery than the previous trials.

- Holes were present but not as noticeable.

- White marks appeared on the surface.

Wood

- Initial mass: 1320 g; final mass: 1441 g (water absorption: 121 g).

- Sample had a pre-existing deep cut and holes.

- Similar white area as in Trial 2 was observed.

Key Observations and Trends

- Surface Roughness Increases Water Absorption

- In Trial 2, the roughened samples showed more pronounced holes and cracks, supporting the idea that the surface texture affects water penetration.

- Submersion Time Impacts the Degree of Change

- The shorter submersion period (Trial 3) led to less visible change, particularly for concrete.

- The longer submersion periods (Trials 1 & 2) led to more deterioration, especially in wood.

- Brick and Concrete Showed Whitening and Small Cracks

- Whitening appeared in all trials, possibly due to mineral deposits.

- Brick showed more visible cracks compared to concrete.

- Wood Absorbed the Most Water

- Significant peeling and texture change compared to other materials

- Quantitative value of water absorption indicates rapid water absorption likely due to high porosity levels.

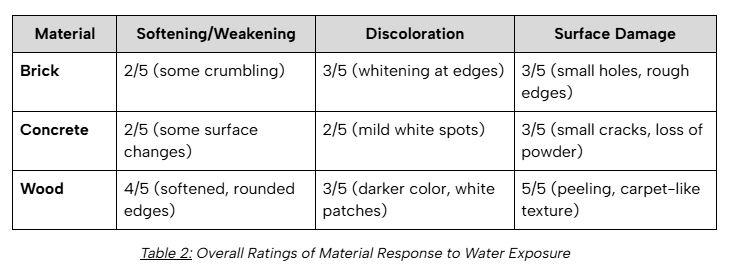

Rating Scale

Key:

- Softening or weakening: 1 = no change, 5 = severely weakened or crumbling

- Discoloration: 1 = no change, 5 = extreme color shift

- Surface damage: 1 = no cracks or swelling, 5 = severe cracks and deformation

The following table presents the overall ratings across the three trials, summarizing how each material responded to water exposure.

Analysis

Overview of Results

The experiment aimed to examine how different building materials—brick, concrete, and wood—respond to prolonged water exposure. Across three trials, each material displayed varying levels of softening, discoloration, and surface damage. Wood showed the most deterioration, while brick and concrete demonstrated moderate changes.

Material Comparisons

Brick

- Softening: Minimal softening, though some edges became crumbly.

- Discoloration: Whitening was observed at the edges and surfaces.

- Surface Damage: Small holes and cracks formed, emphasizing the porous nature of brick.

- Key Observation: Porous structure absorbed water, but the material remained structurally intact compared to wood.

Concrete

-

Softening: Slight weakening, especially in roughened areas.

- Discoloration: Minor white patches appeared.

- Surface Damage: Small cracks and loss of powdery residue occurred.

- Key Observation: The material maintained its structure, but the presence of air pockets and powder loss indicated gradual degradation.

Wood

-

Softening: Severe weakening, rounded edges, and increased softness.

- Discoloration: Darkened significantly with white patches appearing.

- Surface Damage: Peeling layers created a carpet-like texture.

- Key Observation: Wood absorbed the most water, making it highly vulnerable to water-related damage.

Impact of Additional Factors

-

Surface Roughness: In Trial #2, the roughened surfaces absorbed more water, causing more visible damage in all materials.

- Submersion Time: Trial #3, with the shortest exposure time, resulted in fewer visible changes, suggesting that longer exposure intensifies deterioration.

Conclusion

The results of this experiment support my hypothesis that different building materials respond differently to water exposure. Wood proved to be the least resistant, absorbing a significant amount of water and deteriorating the fastest. Concrete and brick exhibited more durability, with concrete remaining relatively stable, while brick showed some crumbling and whitening due to its porous structure,

While these conclusions are somewhat subjective, given the lack of specific quantitative measures, a holistic view of the trials leads to a clear conclusion:

Although these conclusions are partially subjective as there is not a specific quantitative measure to determine whether concrete or brick was most durable, considering all trials holistically allows me to come to a conclusion.

- Best Material for Water Resistance: Concrete, due to its stable structure after exposure.

- Worst Material for Water Resistance: Wood, which weakened and deformed the most.

This experiment not only confirmed the varying water resistance of these materials but also provided valuable insight into their suitability for construction in areas prone to flooding or heavy rainfall. The findings can contribute to further research on material durability, helping in the design of more resilient structures.

Application

Discussion

The results of this experiment are significant because they highlight how various building materials respond to water exposure, crucial for construction in flood-prone areas or regions with heavy rainfall. Understanding the durability of materials like brick, concrete, and wood in water can help engineers and architects make infrared decisions when selecting materials for buildings, roads, and other structures. These findings can contribute to the development of more resilient buildings, improving safety and longevity in vulnerable areas.

In the future, I would expand this experiment to include more materials, like plastic, which was initially planned for the study. Although I couldn’t obtain suitable samples in time, research shows that plastics are generally water-resistant and do not absorb water like the other materials. Testing plastic could offer a more comprehensive understanding of material performance.

Additionally, as I worked on the project, suggestions from my science fair coordinator led me to think about testing water’s impact on roads. Since roads are exposed to heavy wear and tear, and given the high cost of concrete, exploring more durable yet cost-effective alternatives to materials like asphalt could significantly benefit infrastructure sustainability.

Real-World Applications

Flooding often involves high-pressure water movement, such as storm surges or tsunami, which can cause both absorption and physical damage to buildings. Future experiments could simulate these extreme conditions by using pressurized water systems to better understand how materials withstand the force of moving water. This approach would allow for more realistic observations of erosion, cracking, or displacement, offering valuable insight for disaster preparedness.

Limitations and Future Improvements

Several limitations impacted the experiment:

- Inconsistent Submersion Periods: Future trials should ensure equal submersion times to maintain consistency.

- Inability to Weigh Brick and Concrete: A stronger, more precise scale would improve the accuracy of water absorption measurements.

- Additional Material Testing: Including more building materials (e.g., metal, treated wood) could provide a broader analysis.

Overall, this experiment highlighted the importance of material selection in construction, especially in areas affected by flooding or high moisture exposure. Future research could focus on treatment methods that improve water resistance in each material, as well as explore the durability of newer alternatives.

Sources Of Error

During submersion, the wood samples floated, preventing full submersion and causing uneven water absorption. This likely impacted the accuracy of absorption measurements.

The scale was highly sensitive, causing small fluctuations in readings, particularly for the wood samples. Environmental factors, such as temperature, humidity, and airflow, could have also influenced absorption rates, leading to discrepancies in the results.

Variations in material composition, density, or moisture content may have also affected absorption, contributing to result variability. Additionally, one of the brick samples was larger, which likely increased its absorption rate due to a larger surface area.

To minimize these errors, careful handling, precise measurements, and controlled conditions are essential.

Citations

Ambegaonkar, R. (2024, December 10). Key Factors for Selecting the Right Building Materials. Nearby Engineers. https://www.ny-engineers.com/blog/factors-to-consider-when-choosing-building-materials

Bigrou, R. (2024, December 2). Top Sustainable building materials for Eco-Friendly Construction - Green Building Solutions. Green Building Solutions. https://greenbuildingsolutions.org/top-sustainable-building-materials-for-eco-friendly-construction/

Blackwell, C. (n.d.). Types of bricks and 15 Interesting uses of brick | Royalmasonry.ca. https://royalmasonry.ca/blog/types-of-bricks-and-brick-uses/

Brey, J. (2009). New Residential House; Architectural Asphalt Shingle Roof, Vinyl Siding, Gables - stock photo. [Photograph]. Getty Images. https://www.gettyimages.ca/detail/photo/new-residential-house-architectural-asphalt-shingle-royalty-free-image/157420126?searchscope

Calgary Herald. (2024, June 10). Calgary’s great June flood of 1929. CalgaryHerald. https://calgaryherald.com/news/local-news/calgarys-great-june-flood-of-1929

Caulfield, J. (2022, June 28). How to Cite an Image | Photographs, Figures, Diagrams. Scribbr. Retrieved March 4, 2025, from https://www.scribbr.com/citing-sources/cite-an-image/

CBC News. (2013, July 29). Harry Sanders: A quick history of Calgary floods: Worst flood to hit Calgary was in 1879, according to historian Harry Sanders. CBC. https://www.cbc.ca/news/canada/calgary/harry-sanders-a-quick-history-of-calgary-floods-1.1313298

Commemorating the 2013 floods. (n.d.). https://www.calgary.ca. https://www.calgary.ca/water/flooding/flood-commemoration.html

CTV News. (2023, June 21). How Calgary has changed since the 2013 flood [Video]. YouTube. https://www.youtube.com/watch?v=MDrnookLl2U.

Doyle, P. M. (2021). A pile of wood sitting next to each other. [Photograph]. Unsplash. https://unsplash.com/photos/a-pile-of-wood-sitting-next-to-each-other-yVRn-d6JGzo

Flood resiliency improvements since 2013. (n.d.). https://www.calgary.ca. https://www.calgary.ca/water/flooding/flood-resiliency-improvements.html

Flooding in Calgary - Flood of 2013. (n.d.). https://www.calgary.ca. https://www.calgary.ca/water/flooding/history-calgary.html

Green, E. (2024, July 1). Traditional vs. Sustainable Building Materials: Cost And Performance. Sigma Earth. https://sigmaearth.com/traditional-vs-sustainable-building-materials-cost-and-performance/

Haupt, M. (2020). Brown and white brick wall. [Photograph]. Unsplash. https://unsplash.com/photos/brown-and-white-brick-wall-GN2IqNRlPXs

Lightbody, L., & Watts, B. (2020, October 1). Repeatedly flooded properties will continue to cost taxpayers billions of dollars. The Pew Charitable Trusts. https://www.pewtrusts.org/en/research-and-analysis/articles/2020/10/01/repeatedly-flooded-properties-will-continue-to-cost-taxpayers-billions-of-dollars

McCoy, H. (2023, June 15). On Calgary’s 10-year flood anniversary, businesses are more ready: UCalgary researchers suggest businesses might be more resilient in the post-COVID world if Calgary flooded again. News. https://ucalgary.ca/news/calgarys-10-year-flood-anniversary-businesses-are-more-ready

National Geographic Society. (2024, July 19). The Many Effects of Flooding. National Geographic. https://education.nationalgeographic.org/resource/many-effects-flooding/4th-grade/

Pinconsult Associates Limited. (2022, July 27). 15 Factors Affecting the Selection of Construction Materials. LinkedIn. https://www.linkedin.com/pulse/15-factors-affecting-selection-construction-materials-limited/

Rider, D. (n.d.). Choosing the right construction materials can make the difference. If. . . https://www.if-insurance.com/large-enterprises/insight/choosing-the-right-construction-materials

Rm4l. (2024, November 5). 10 Types of building materials: properties, applications, and lifespan. RM4L. https://rm4l.com/types-of-building-materials/

Rodriguez, F. (2025, February 25). Plastic | Composition, History, Uses, Types, & Facts. Encyclopedia Britannica. https://www.britannica.com/science/plastic

Team, I. (2024, November 4). Comparing Different Types of Building Materials: Strengths and Weaknesses | illustrarch. Illustrarch. https://illustrarch.com/articles/35805-comparing-different-types-of-building-materials.html

Torres, E. (2014). Concrete Cubes. [Photograph]. Flickr. https://flic.kr/p/k6vV5S

Trusscore. (2025, February 6). Flood resistant home design. Trusscore. https://trusscore.com/blog/flood-resistant-home-design.html

Understanding Types of Bricks & their Properties in Construction | UltraTech. (n.d.). https://www.ultratechcement.com/for-homebuilders/home-building-explained-single/descriptive-articles/types-of-bricks-and-its-properties

Un-Water. (n.d.). Water and Disasters | UN-Water. UN-Water. https://www.unwater.org/water-facts/water-and-disasters

What are the best materials to use for a bridge that is both functional and beautiful? (n.d.). https://www.linkedin.com/advice/0/what-best-materials-use-bridge-both-functional-obxbe

What is Concrete? Types, Composition & Properties | UltraTech. (n.d.). https://www.ultratechcement.com/for-homebuilders/home-building-explained-single/descriptive-articles/what-is-concrete-types-composition-properties-and-uses

Wooduchoose. (n.d.). What is Wood | Wood Info. Wooduchoose - the Home of Wood. https://www.wooduchoose.com/what-is-wood/

Team, I. (2024, November 5). Guide to Choosing the Right Building Materials: Sustainability, Cost & Durability Tips | illustrarch. Illustrarch. https://illustrarch.com/articles/architectural-sustainability/35803-guide-to-choosing-the-right-building-materials-for-project.html

Zurowski, M. (2024, June 14). Nine unforgettable historic flood photos: When rivers rage in southern Alberta. CalgaryHerald. https://calgaryherald.com/news/local-news/southern-albertas-flooding-history

Acknowledgement

I would like to express my sincere gratitude to Mr. Nayak for his guidance and support throughout the completion of this project. I also thank my parents for assisting with the purchase of materials and sharing their valuable knowledge. A special thanks to my mom for helping with the materials and my dad for the large trifold and transportation. Lastly, I am grateful to Sean Savage and Lance Beairsto at BURNCO for creating the concrete samples specifically for my experiment. Your contributions have been invaluable.