3D Printing a Backyard Chicken Coop: An Alternative to Factory Farming

Grade 10

Presentation

Problem

Background

Factory farming is a method of raising large numbers of animals in confined spaces in order to meet demands for meat and animal products. While it is a cost-effective farming method, it can create serious issues in terms of animal welfare, human health risks and environmental damage. This project began as a part of a design class I took in June, where I researched the harms of factory farming, specifically on chickens. I then explored potential solutions to the issue, such as people having chicken coops in their own backyards. Since then, I have expanded on my initial work by conducting further research and refining my design ideas. My goal is to create a backyard chicken coop design that can be used to reduce the issue of factory farming for chickens. My design will be unique because of its combination of having a modern aesthetic, being made out of sustainable materials and having practical features that address common issues with backyard coops, including having limited access for cleaning or poor ventilation.

Project Plan

Table #1: A 10 step plan to guide my science fair project

| Step | Task to complete | What this will involve |

| 1 | Conduct research | I will learn about the harms of factory farming and understand its various impacts. I will present my research in a format that makes it easy for others to see what I have learned. |

| 2 | Justify my solution | I will explain why backyard chicken coops are a good alternative to the factory farming of chickens. |

| 3 | Analyze existing products | I will evaluate an existing backyard chicken coop to identify its strengths and weaknesses so that I can improve my own design. |

| 4 | Create design specifications | I will come up with clear goals and requirements for my backyard chicken coop design. |

| 5 | Make design sketches | I will draw sketches of my design based on the specifications I create. |

| 6 | Create a final product | I will use the 3D printing software Fusion 360 to create a detailed, three-dimensional model of my chicken coop design. |

| 7 | 3D print the product | I will print the final design using a 3D printer at my school so that I have a physical prototype to show at the science fair. |

| 8 | Evaluate the design | I will assess my final product to see if it meets the design specifications I created. |

| 9 | Explain how the design could practically be used | I will look into how my chicken coop design can be sold so that people can easily buy and assemble the product for their own use, allowing the design to help with sustainable farming in the real world. |

| 10 | Reflect on the project | I will reflect on what I learned and the challenges I faced while completing my science fair project. |

Step 1: Conduct Research

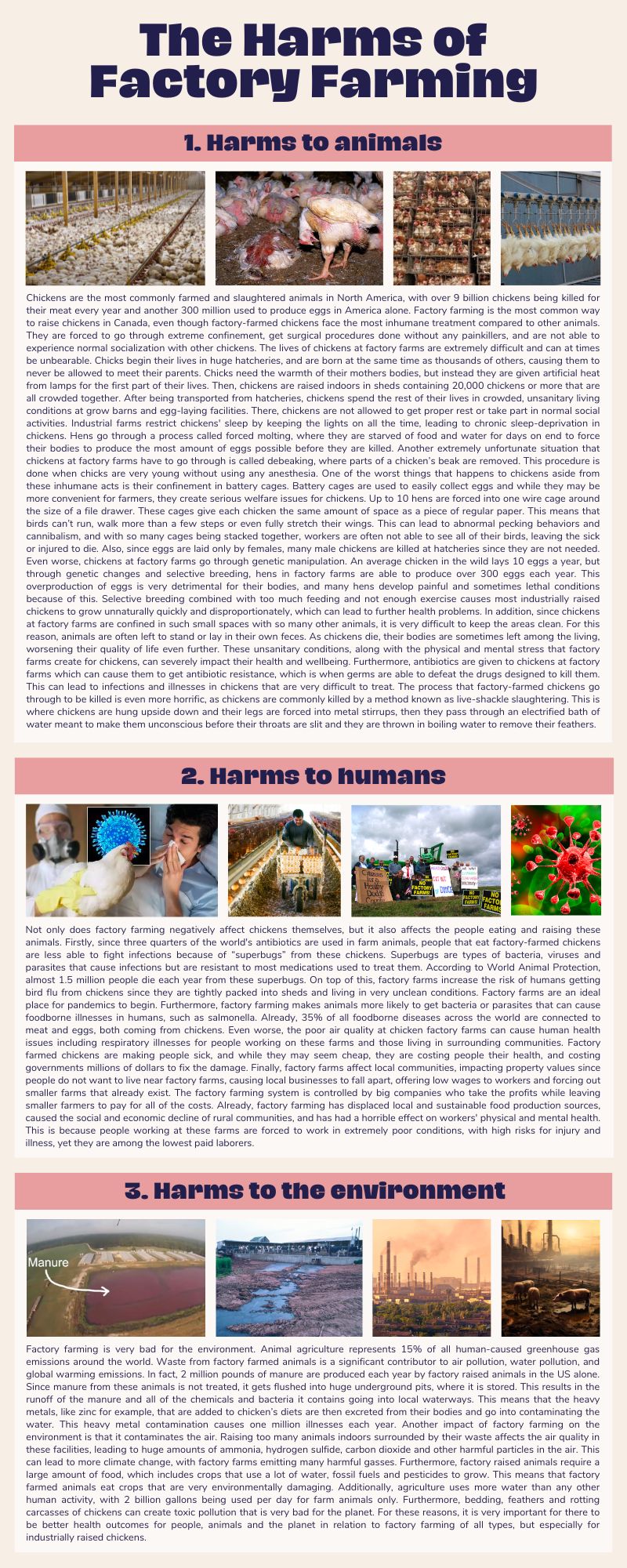

To learn about the negative impacts of factory farming and ultimately be able to share this information with others, I have done some online research and created the infographic below. Making this infographic has allowed me to understand the issue of factory farming in more depth so that I can then come up with a better solution.

Figure #1: An infographic about the harms of factory farming to animals, humans and the environment

Method

Step 2: Justify my solution

In my design class a few months ago, I learned that backyard chicken coops are an effective solution for factory farming concerns. I have done more research about residential chicken coops and believe that they are a beneficial way to mitigate the issue. I want to ultimately create my own backyard chicken coop design. So, I have done more research to create another infographic that highlights the benefits of residential chicken coops.

Figure #2: An infographic about the benefits of backyard chicken coops, including providing nutritious food, producing fertilizer and having new pets

Step 3: Analyze existing products

I have evaluated an existing backyard chicken coop design I found using the acronym ACCESS FM. In addition to this analysis, I got feedback from family friends who built their own residential chicken coop. They said that their main concerns with their chicken coop design was that the coop lacked proper ventilation and was challenging to clean since humans couldn’t easily enter the coop. This research will help me refine my own design so that it addresses these common concerns.

Figure #3: An explanation of ACCESS FM-based analysis

Figure #4: An existing residential chicken coop design

Table #2: Analyzing the existing design

| Aesthetics | This chicken coop looks very modern. It is made of mesh (hardware cloth), wood and wire to support the structure. It has a geometric design and has an angled dome shape. |

| Cost | This chicken coop likely has a low cost and could be made at home. Wood, metal sticks and mesh are materials that can be found at many local stores and do not have a high price. |

| Customer | People who want to have a backyard chicken coop will use this product. |

| Environment | This chicken coop is fairly environmentally friendly as it is not made of plastic. Instead it is mostly made out of metal and wood, which are materials that have a lower environmental impact than others. However, these items are still not incredibly sustainable, but this problem could be fixed by using an eco-friendly type of mesh and less wood. |

| Size | The chicken coop is 20 feet large. It has enough space to fit many chickens and even humans. This means that it is very comfortable and can easily be used. The design would be more practical for people to have in their backyards if it was a bit smaller, around 8 feet instead of 20. |

| Safety | The chicken coop is very safe. It is made out of a sturdy material to protect the chickens inside and it is stuck to the ground so it won’t fly away in case of wind. There are no sharp materials poking out and the coop is well constructed. |

| Function | The function of this backyard chicken coop is to be a home for chickens so that they can live in it and lay eggs. It provides chickens with a safe shelter that protects them from harm and gives them the resources they need to survive. The chicken coop fulfills its purpose because it is a functioning habitat for chickens. |

| Material | The chicken coop is made out of mesh, wood and metal rods. These materials are often used for agricultural purposes because they are strong, sturdy and fairly weather resistant. The coop’s metal frame was probably bought from a hardware store and the rest of the parts could easily be made at home. It is not too complicated to make and someone that knows how to do light construction work could easily build this chicken coop. |

Step 4: Create design specifications

I have created five of my own specifications for my backyard chicken coop design, and have researched specifications for residential coops created by the Alberta government. I will try to make sure that my design meets all of these specifications. Based on my research, I have determined that having good ventilation and offering easy access for humans to enter the coop are some of the most essential aspects of having a functional chicken coop.

Table #3: Backyard chicken coop design specifications I have created and the reasoning behind these specification

| Specification | Reasoning |

| The chicken coop must be comfortable for the chickens that live in it. | The chicken coop should have enough space for each hen to prevent overcrowding. It should also have ventilation to make sure that there is good air quality. Making sure that this specification is met is important because the chickens must be comfortable in order to be healthy and ultimately produce more eggs. |

|

The chicken coop must be aesthetically pleasing. |

The chicken coop should be made out of materials and colors that look natural, so that the design of the coop complements the environment where it is placed and does look strange. It should also not be overly large, so that people actually want to put it in their backyards. Making sure that this specification is met is important because more people will want to have backyard chicken coops if they look visually appealing. |

| The chicken coop must be designed using durable and weather-resistant materials. | The chicken coop should be constructed using high quality materials such as treated wood, steel and weather-proof paint. The roof should also be strong to prevent any water from leaking into the coop. Making sure that this specification is met is important because having a durable chicken coop will allow it to be functional for a longer period of time. The coop should protect the chickens inside of it, be cost-effective and be worthwhile for people to have in their backyards. |

|

The chicken coop must be easy for humans to access. |

The chicken coop should provide easy access to humans for things like feeding, cleaning or egg collection purposes. Making sure that this specification is met is important because allowing humans to have easy access to the coop will allow humans to clean the coop more often and more thoroughly since it will be accessible, thus improving the well-being of the chickens. Also, humans will be able to save a lot of time and effort when collecting eggs and providing food for the chickens if this specification is met. |

| The chicken coop must have a sustainable and eco-friendly design. | The chicken coop should use renewable or recycled materials that have a limited impact on the environment. Making sure that this specification is met is important because one of the main goals of this project is to create a sustainable solution to factory farming, and this can occur by using eco-friendly materials that are better for the environment. |

Table #4: Backyard chicken coop design specifications created by the Alberta government

| The chicken coop must be a maximum of 10 square meters. |

| Each hen in the chicken coop should have a minimum of 0.37 square meters of space. |

| The chicken coop should be able to fit 5-10 hens. |

| The chicken coop should have a roof. |

| The chicken coop should have windows. |

| The chicken coop should have venting, preferably on 2 sides of the coop. |

| The chicken coop should have a waterer and feeder. |

| The chicken coop should have roosting platforms or bars. |

| The chicken coop should have nest boxes. |

| The chicken coop should have an outdoor run attached to the coop that provides a minimum of 0.92 meters of enclosed outdoor space for each hen. |

| The outdoor run must be fully enclosed with mesh, including the roof and sides. |

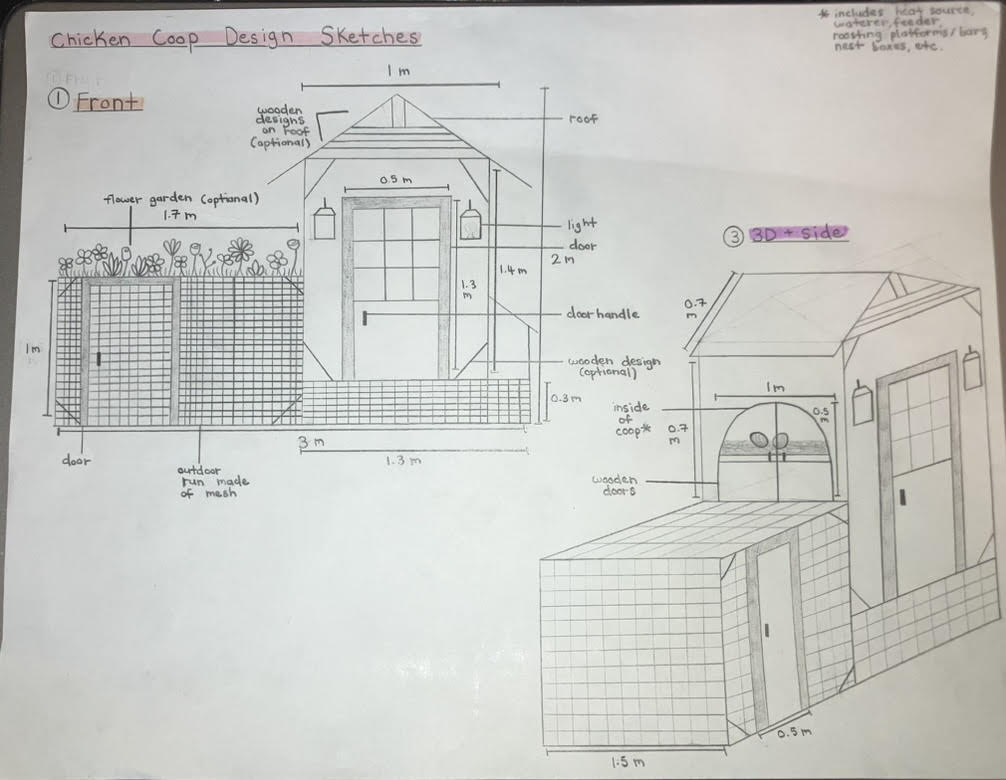

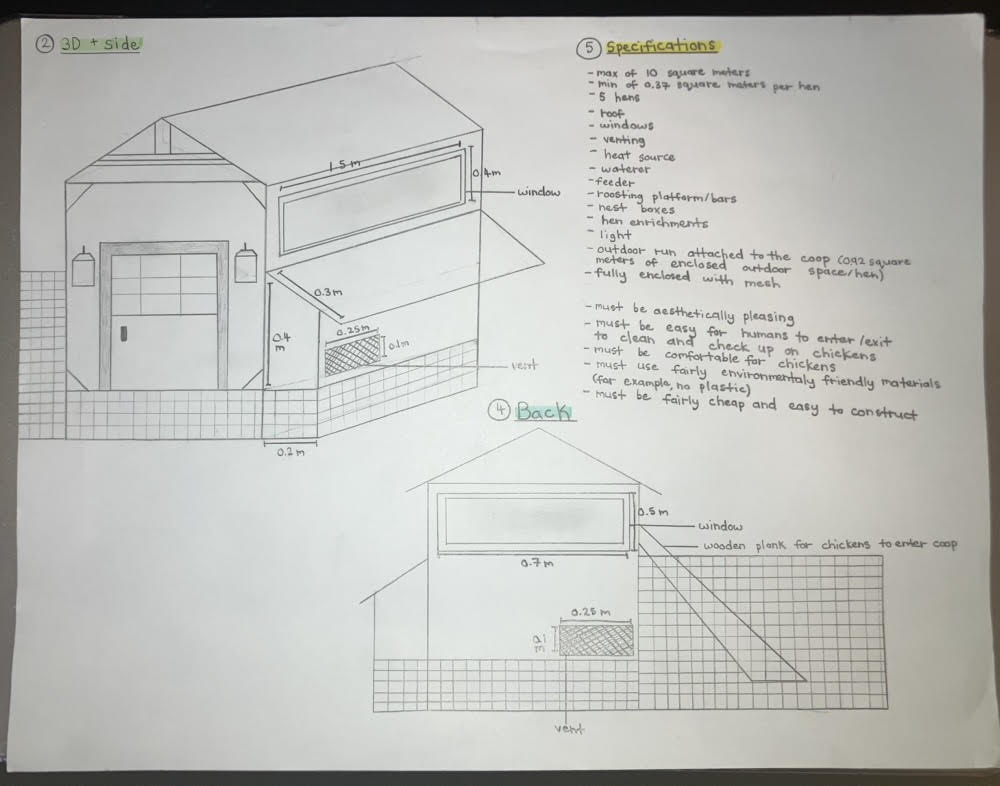

Step 5: Make design sketches

Using the design specifications I created, I have created a plan for my backyard chicken coop design. I drew sketches of my design on paper, making sure the sketches were labelled with the correct dimensions and materials. These sketches include four different views of my chicken coop design, so that I have a clear idea of what I want to 3D print as my final product. This may not be exactly what my end product looks like, but it is similar to the type of backyard chicken coop I am aiming to produce.

Figure #5: The front and side views of my chicken coop design

Figure #6: The side and back views of my chicken coop design

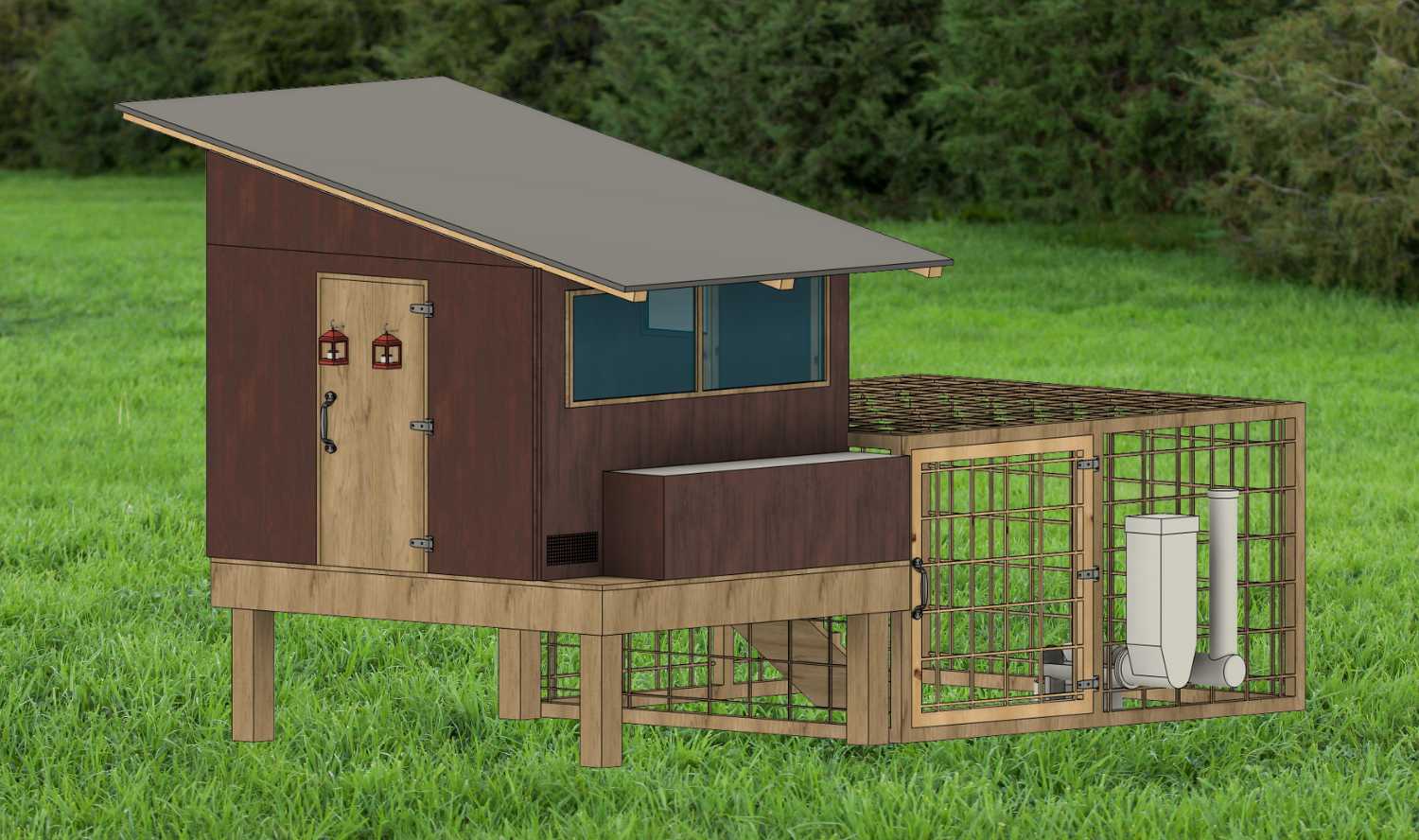

Step 6: Create a final product

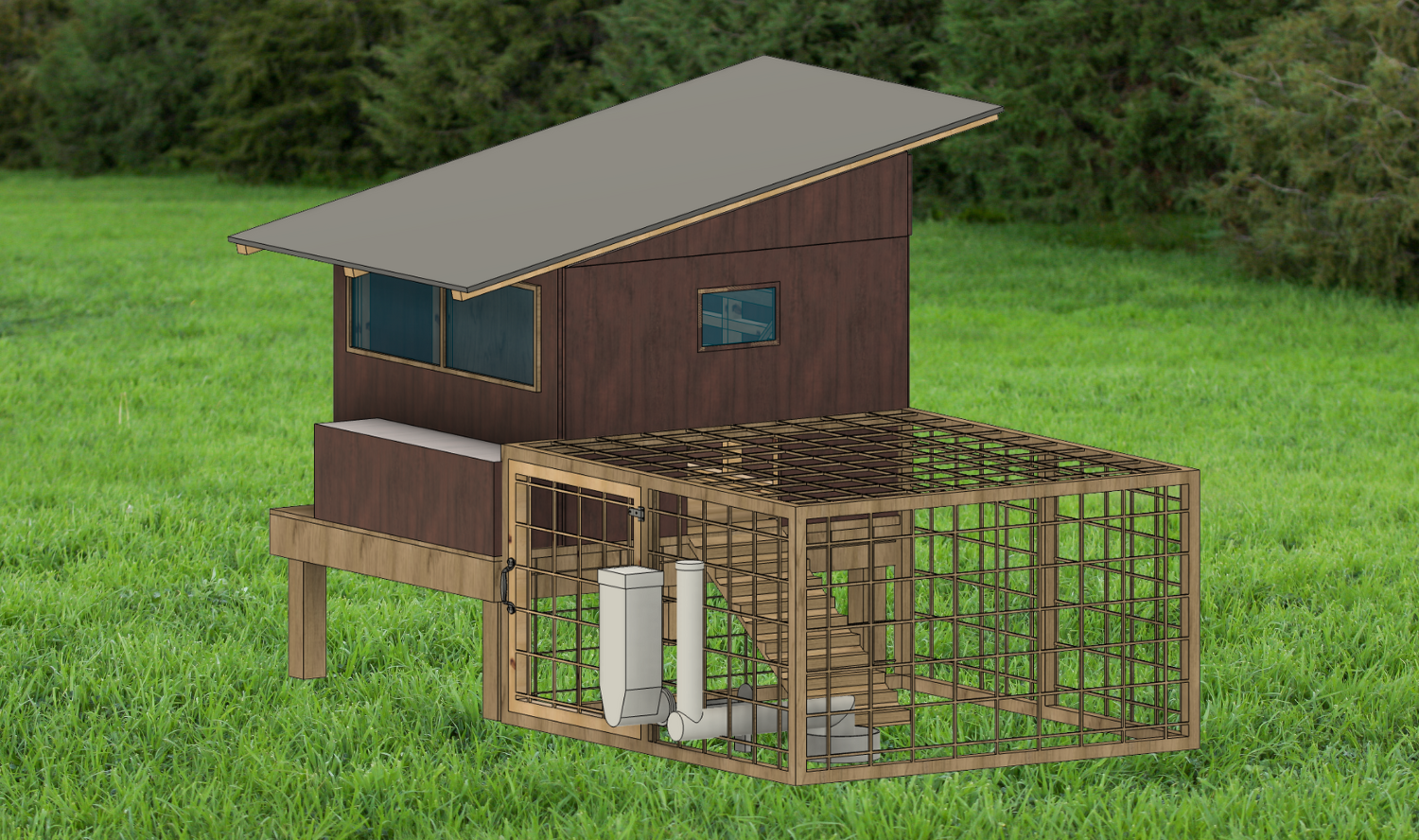

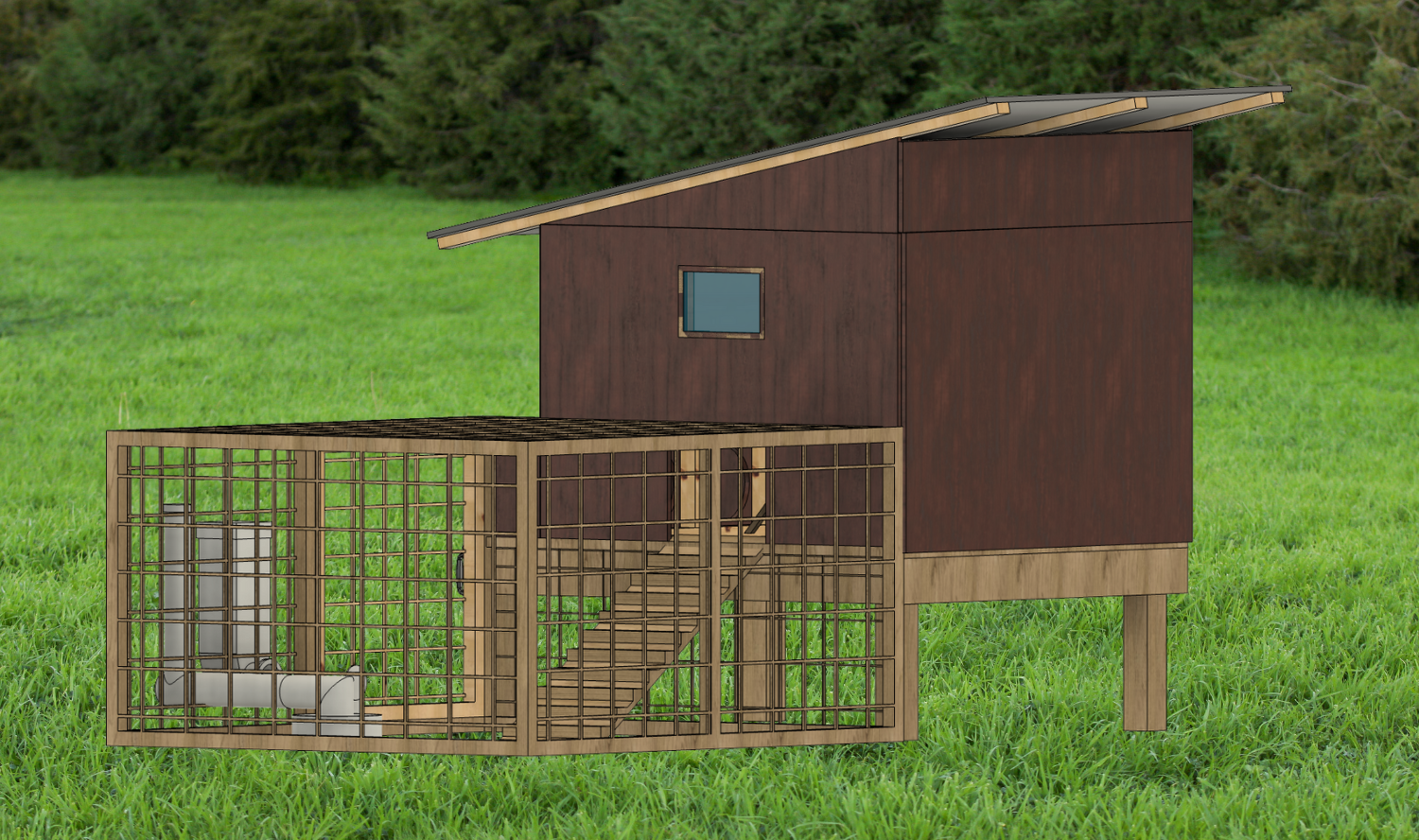

Figure #7: Front view of the chicken coop

Figure #8: Side view of the chicken coop

Figure #9: Back view of the chicken coop

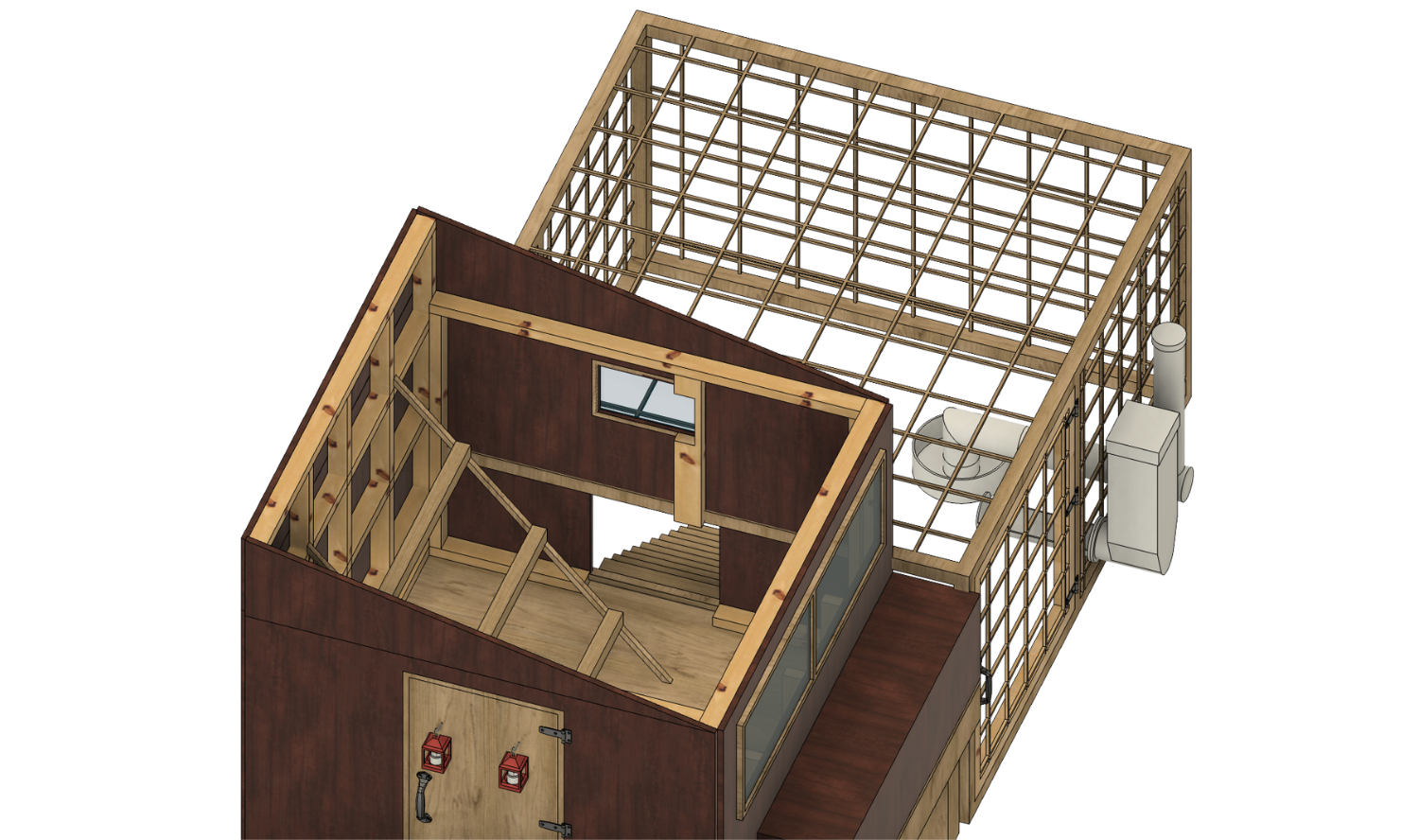

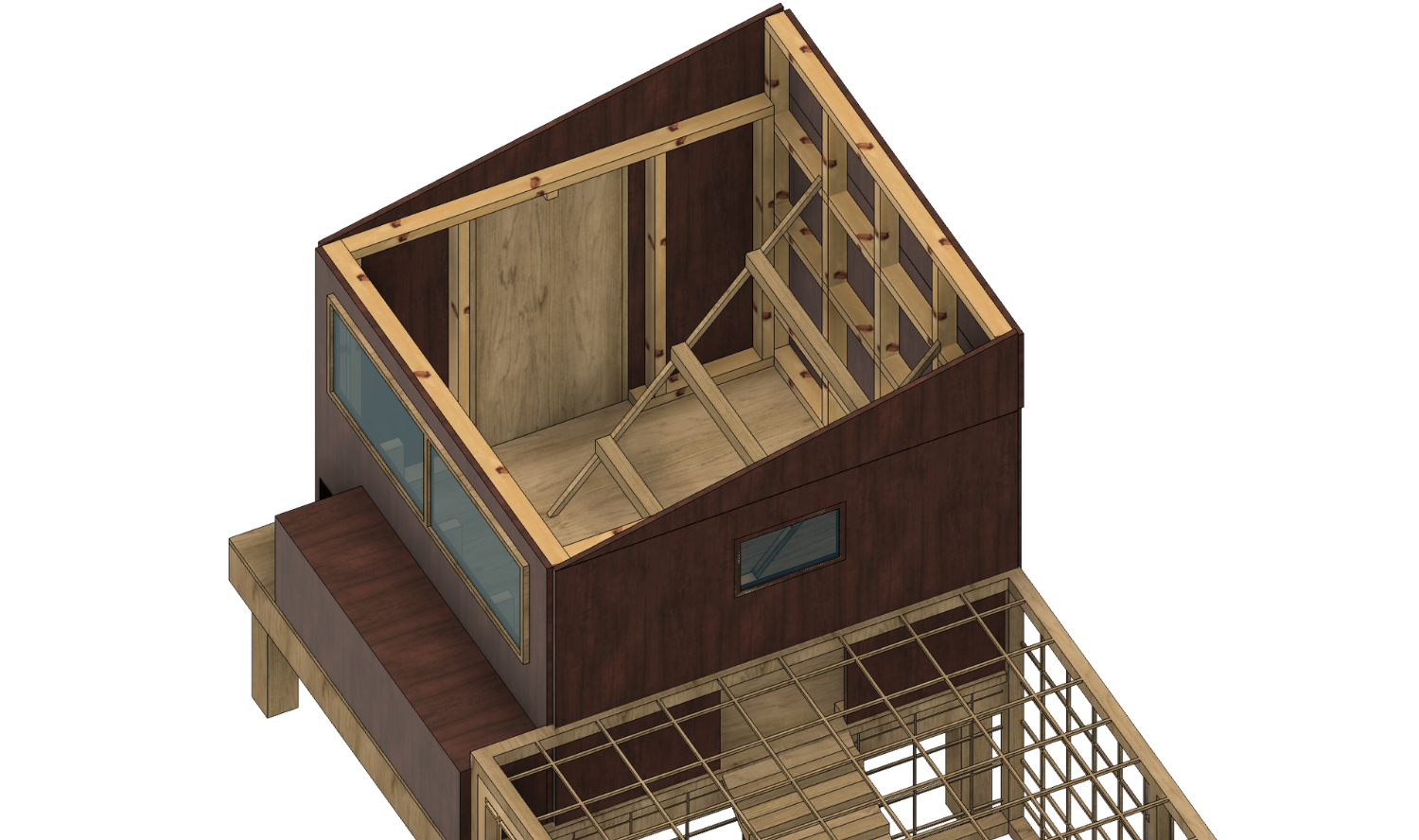

Figure #10: Inside back view of the chicken coop

Figure #11: Inside front view of the chicken coop

Figure #12: Inside side view of the chicken coop

Figure #13: Inside side view of the chicken coop

Step 7: 3D print the product

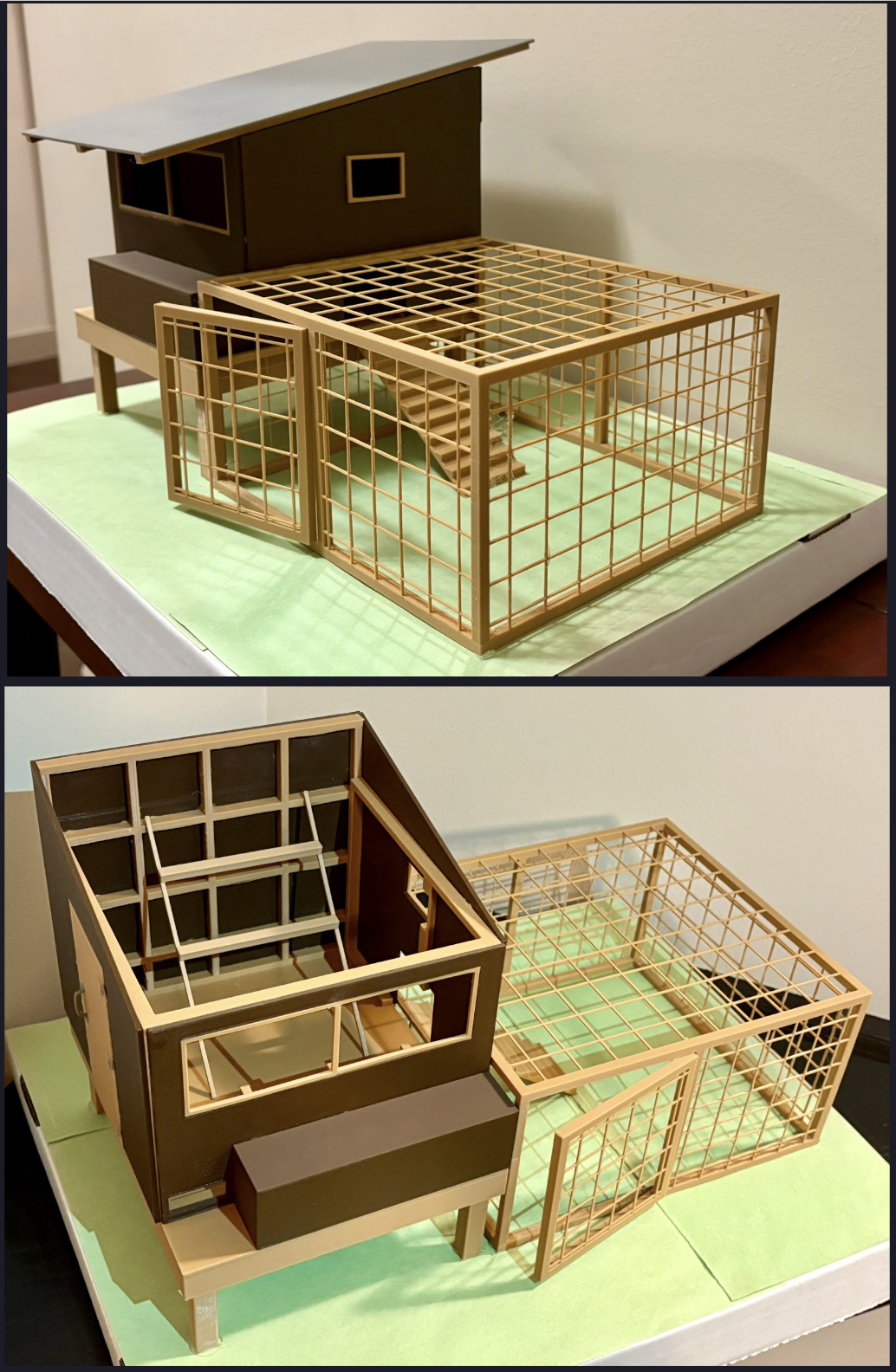

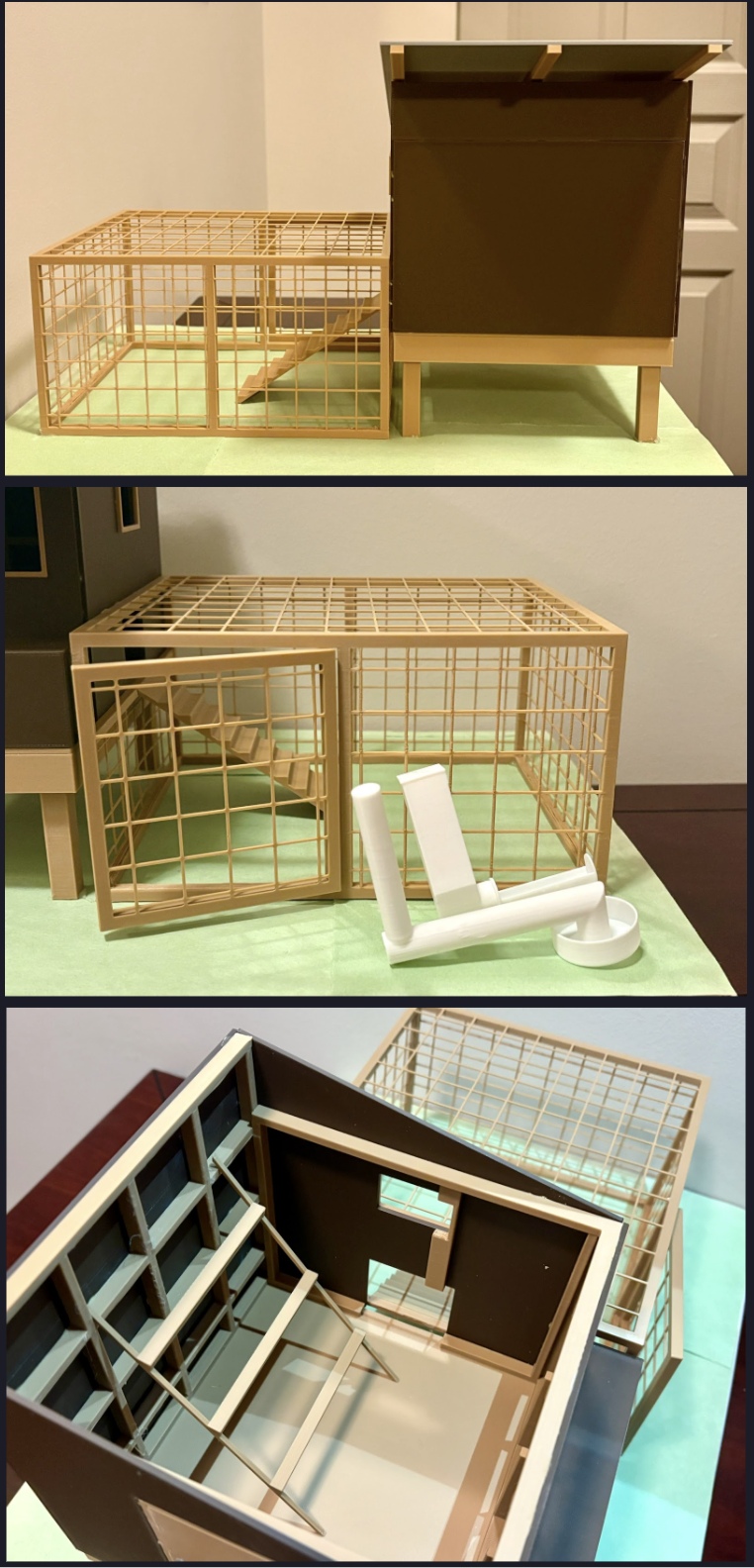

Figure #14: Side views of the 3D-printed chicken coop model

Figure #15: Back views of the 3D-printed chicken coop model

Figure #16: Inside views of the 3D-printed chicken coop model

Figure #17: Other miscellaneous views of the 3D printed chicken coop model including the waterer/feeder

Analysis

Step 8: Evaluate the design

Table #5: Evaluating whether the design specifications I created for my backyard chicken coop innovation were unmet, partially met or fully me

|

Design specification |

Was this specification unmet, partially met or fully met? |

| The chicken coop must be comfortable for the chickens that live in it. | This specification was fully met because there is enough space for 5-10 chickens to live comfortably, with the coop being large enough for each chicken to receive ample room. The design specifications for the measurements of the chicken coop, which were created based on the Alberta government’s regulations, have all been met. I have also included venting that is made out of mesh to make sure that the air inside of the coop is clean and safe for all of the chickens to breathe. Additionally, the chicken coop has an outdoor run, feeder/waterer, roosting bars, nesting boxes and other features that make it more comfortable for chickens. |

| The chicken coop must be aesthetically pleasing. | This specification was fully met because the chicken coop is brown and gray, which are colors that can blend into most environments. These colors are not extremely bright so they will look natural in an outdoor setting. I have also used a lot of wood in the design of the chicken coop, which is very easy to camouflage in the outdoors. The coop has a very modern and minimalist design, with a slanted roof and sleek edges to make the design have a pleasing exterior. |

| The chicken coop must be designed using durable and weather-resistant materials. | This specification was fully met because the chicken coop is made out of a steel roof and wood. Since the roof is made out of steel, it is completely weather resistant and will be functional for many years to come. Also, the pressure-treated wood used on the walls of the coop and the frame of the outdoor run area is also quite weather resistant and long-lasting, as long as it is well maintained. Both wood and steel are strong materials that will not break or get damaged easily so that they can last for multiple years while protecting the animals inside of the coop. |

| The chicken coop must be easy for humans to access. | This specification was fully met because the chicken coop is tall enough for humans to easily clean the inside of it, provide food/water for the chickens and collect eggs. It has a large door at the front with a handle for humans to enter or exit the coop. The outdoor run also has a door so that humans can enter the coop, and the waterer and feeder placed in the outdoor run have easy accessibility from above so that humans can quickly give the chickens food and water. The design makes it very convenient for humans to do maintenance within the coop. |

| The chicken coop must have a sustainable and eco-friendly design. | This specification was fully met because the chicken coop is made out of steel and wood which are two eco-friendly materials. Steel is an especially sustainable material because it is permanent, reusable, recyclable and does not harm the environment very much, so it meets this specification. Also, while wood is not the most eco-friendly material to use in the design because it involves cutting down trees, it is still better than using other materials (such as plastic) which cause more environmental damage. So, even though these materials may not be the most sustainable compared to all other options, they work well in this design. |

Step 9: Explain how the design can practically be used

My 3D printed chicken coop design could be sold on platforms like Etsy, Thingiverse or eBay, or through specific farming suppliers. These platforms would allow individuals and small farm owners to easily use my design.

To create a commercial-grade version of the coop, I would need to use stronger materials and 3D printing filaments. This would include using PETG, ASA, or carbon-fiber-reinforced filaments, which are more durable than standard PLA filaments (which have been used in the current model), and cost around 50 to 150 dollars per kilogram. A larger coop capable of housing 10 or more chickens would require between 20 and 50 kilograms of filament, leading to material costs of around 1000 dollars per unit. Additional reinforcements, such as metal framing, UV-resistant coatings and industrial fasteners, could add another 500 dollars to the cost. Based on these factors, a commercial-grade 3D printed chicken coop could be priced at around $1500.

Other ways to monetize the design include selling STL files for farm-scale coops, offering a subscription model where customers could receive custom blueprints of chicken coop designs like mine, or creating partnerships with poultry equipment companies to integrate my design into their products. These strategies would help make my chicken coop design practical, scalable and widely accessible, and are future steps that I could take. As a part of this, it would be important to have simple assembly instructions for the coop so that people with limited construction experience could use the product.

In order to sell the product, further testing would be required to ensure that the design is safe and functional for chickens. This would include testing the coop’s airflow and ventilation, drainage efficiency, temperature regulation across different seasons, waste management, structural integrity, and protection against predators. Conducting these tests would require printing a larger model so that the design's safety and practicality could be verified before making it available for sale.

Conclusion

Step 10: Reflect on the project

I have created a few reflection questions to help me share my final thoughts about the project.

1. What parts of my sustainable coop design am I especially proud of?

First, I am proud of the overall appearance and aesthetic of my chicken coop design. It looks professional and has a simple design that is visually appealing. By using a slanted roof and a minimalistic style to make the coop, more people would be encouraged to purchase my design since it can easily blend into its environment. I made my chicken coop look aesthetically pleasing by including many small details to enhance the design, such as adding door handles/hinges, lights, venting, mesh and sleek windows. Second, I am proud of the outdoor run that I have created beside the coop. It took me a lot of time to learn how to create a mesh pattern, but eventually, by using the pattern tool on Fusion 360, I was able to create a realistic mesh design. This part of the coop has made the entire design much more realistic, and would be helpful for the chickens living inside the coop by providing them with a large outdoor space to roam free. Third, I am proud of the inside of the chicken coop. I have included roosting bars and nest boxes to make the design as functional as possible, providing chickens the tools they need to produce lots of eggs. I think that spending time adding detail to the inside of the coop was very beneficial. Finally, I am proud that my chicken coop has met all of the required design specifications, including the ones I created and those from the Alberta government. I made sure that all specifications were met so that my design completely aligns with the government’s requirements and would be completely safe for chickens.

2. What was challenging?

The most challenging concept for me was to learn how to use Fusion 360 since I had limited experience with using it prior to this project. However, I overcame this challenge by simplifying what was initially a very complex design and doing research to help me learn. I watched many different tutorial videos to figure out how to use the design software. While this factor made the project more challenging, I think that the time I spent learning how to use Fusion 360 was completely worth it as I am pleased with my final design. I also incorporated elements that other Fusion 360 users had made into my own design by importing the door handles/hinges and waterer/feeder from other sources instead of making them myself. There were many times when I felt confused and even frustrated with Fusion 360, but I was able to ultimately overcome these challenges by getting help and working hard to complete the design.

3. What required creativity and what was awesome about this project?

This entire project required creativity. From brainstorming a list of ideas at the start, to making sketches, and then coming up with a final design idea, creativity was used at every step of the way. I enjoyed having the ability to be creative since I had the freedom to design a chicken coop however I wanted. There were few restrictions and I could create something that reflected my own unique ideas. Specifically, I enjoyed using my creativity to come up with ideas at the start of the design cycle and then to make sketches when solidifying these ideas. It was fun to combine many different ideas into a final design.

I think that this project was awesome because it was informative and practical. Before I even started designing my chicken coop, I learned about why people should have backyard chicken coops in the first place by researching the consequences of factory farming. Then, I created a design that was actually printed and people could use in real life. In fact, my parents have been thinking of having a backyard chicken coop for many years, and showing them my design has given them ideas on how to build their coop in the future. Furthermore, this project has allowed me to learn about the design cycle and gain important skills from this that I can use in the future. It has given me an avenue to be able to come up with a creative solution to a real problem in the world.

4. What could be improved about my project and how?

There were a few elements of my design that I included in my plan for the coop that I didn’t implement in my design on Fusion 360 because I didn’t know how to make them. For example, in my original plan, I wanted to add more details to the coop such as placing wooden embellishments on the outside of the coop and a flower bed on top of the outdoor run to make the coop more visually appealing. I didn’t get to actually include these parts of my plan on Fusion 360 as I realized that designing these details required using tools that I didn’t know how to use. These elements were not very necessary, and I already spent lots of time on other aspects of the design, so I decided to eliminate these details from my final design. If I had more time and were more adept at using Fusion 360, I could have made the design better, but I am still very content with my design as it is right now. Also, if I had more time, I would improve my design further by designing an automated feeding system to dispense food for the chickens in intervals throughout the day. This would make having a backyard coop much more convenient.

Additionally, I faced some difficulties with actually 3D printing my chicken coop design since I had hoped for it to be done at school at a lower cost, but this wasn’t possible in the end. My design teacher at school tried to help me print the coop, but he didn’t have access to the right colors I needed, was unable to print it with all of the details included, and it was very small when a test version was printed. So, I had to reach out to a 3D printing company to print a model of my design. This ended up being beneficial as my final design was printed almost exactly as I had intended it to be. However, even though I used a professional 3D printing company, my design was so complex and intricate that certain details couldn’t be printed and assembled, such as the lights on the chicken coop, the feeder and waterer being inside of the outdoor run or there being hinges on the gate to the run. This could be solved by using an even larger scale company that focuses on 3D printing small details. This would be more expensive but would result in a more accurate 3D print.

The biggest flaw with my project for consumers would be its price. If it were sold at a bigger scale, it would cost around 1500 dollars, which may not be affordable for everyone. However, while the design is somewhat expensive, the benefit of my design is that it comes with everything needed to set up a chicken coop and would require little hassle to assemble. It would be up to consumers to decide whether they want to pay less but spend more time setting up the coop which may not be as professional as this design is, or pay more to have a professional, easy-to-assemble backyard chicken coop. However, I could explore using more cost-effective materials such as bamboo or corrugated metal sheets to reduce expenses while maintaining the durability of the product.

I showed my final backyard chicken coop design to some family friends who have chickens and built their own residential chicken coop, and they thought that my design would be very functional. Also, I was unable to test my design for things like its airflow or drainage because I only printed a small prototype of the model. If I had access to a larger prototype, I could have conducted practical tests to confirm the effectiveness of these features.

Citations

Acknowledgement

I would like to thank my science fair coordinator, Ms. Willoughby, for helping me stay on track and giving me feedback on my project. I would also like to thank my friend Lily for brainstorming ideas for the project with me. Finally, I am thankful to Mr. Schweitzer, my design teacher at school, for teaching me how to use Fusion 360, and Randy Thompson from Affordable 3D for helping me 3D print my innovation.