How Does The Grip Strength of Robotic Prosthetics Hold up to Appendicular Human Limbs?

Grade 8

Presentation

Hypothesis

If the prosthetic is going to mainly be compared in areas of movement and grip, then it will likely not be able to hold objects as efficiently as a regular hand as the structural integrity/design of the build and texture of a prosthetic normally being more bare with less functions and also being harder to replicate.

This is especially applicable to the grip sector of this experiment, as you need the thumb to be far enough from the hand to grasp objects but still be flexible enough to wrap around the object and touch the other fingers to hold it tight. Also, another process that may be difficult is having the 3 phalanges bend individually so it can wrap around the object enough to be held properly and stabilized by the fingertips.

Research

Background Research

Anatomy of the forearm and hand:

The hand is composed of many different types of bones, muscles, and ligaments that allow for a large amount of movement and dexterity. Your wrist is the joint at the end of your forearm. It acts as a hinge between your arm and hand that lets you reposition your hand. Tendons are flexible pieces of tissue that connect bones to muscles. There are two types of tendons: flexor and extensor. These allow for multiple different movements of the hand or joints, such as flexion, extension, and hyperextension. Flexor Tendons run from the forearm and go all the way to the ends of our fingers on the palm side of the hand which gives the ability to bend fingers and make things such as a fist or pinch objects. There is also flexion, flexion is when you bend a joint and the angle of that joint is then decreased. Extensor tendons run underneath the skin alongside the back of your hand and wrist and they control the hand's ability to straighten your fingers and wrists. This can be compared to a pulley system of sorts that allows fingers to be bent or straightened depending on the strain of movement force. These tendons are held in place by the band of the tissue, otherwise known as the retinaculum.

The bones that make up hands are the carpal bones, metacarpal bones, and Phalanges which make up the hands bone structure. The Carpal bones and Metacarpal bones make up the palm of the hand, while the Phalanges make up the fingers. There are three bones which can be distinguished by looking at the space from the palm to the knuckle, and that knuckle to the next knuckle, and so on. The three phalanges that make up each finger are called the Distal Phalange, Medial Phalange, and Proximal Phalange respectively in a top to bottom order. These altogether create the bone structure of your hands. The bones in the forearm connecting to the wrist and hand are the Radius and Ulna.

There are also three muscles called the thenar that arch toward the thumb called the Flexor Pollicis Brevis, Abductor Pollicis Brevis, and the Opponens Pollicis. These are some of the most important muscles in the hand and allow one of the most important functions of the hand, which is to hold or grasp objects as the Abductor Pollicis Brevis pulls away the thumb from the hand and the Flexor Pollicis Brevis move it toward the little or pinky finger. The Opponens Pollicis opposes the thumb and keeps it in that place to allow it to completely stay farther from the index finger and grasp objects.

Tech:

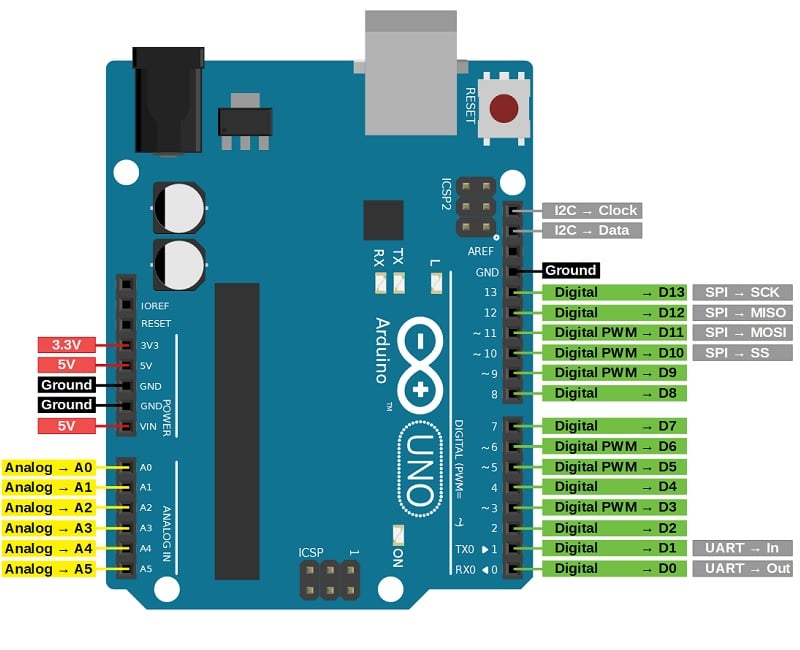

Pinout: The Arduino Uno has 4 types of power pins, the VIN, 5v, 3v3, and GND. The VIN is used to po wer the Arduino board using an external power source. The 5v and 3v3 pins provide regulated voltage to power external components. Finally, the GND (ground) pins are used to close the electrical circuit and provide a common logic reference level throughout the circuit. There are 6 analog pins, labelled from A0 to A5. These pins can read the signal from an analog sensor and convert it into a digital value that we can read. 7 Digital pins, which can be used for both digital input and digital output. PWM is a technique used to encode a message into a pulsing signal. They are composed of 2 components: frequency and duty cycle. PWM frequency dictates how long it takes to complete a single cycle and how quickly it fluctuates from high to low. The cycle determines how long a signal stays high out of the total period. Finally, Serial, Serial communication is used to receive and transmit data between the Arduino board and another serial device.

wer the Arduino board using an external power source. The 5v and 3v3 pins provide regulated voltage to power external components. Finally, the GND (ground) pins are used to close the electrical circuit and provide a common logic reference level throughout the circuit. There are 6 analog pins, labelled from A0 to A5. These pins can read the signal from an analog sensor and convert it into a digital value that we can read. 7 Digital pins, which can be used for both digital input and digital output. PWM is a technique used to encode a message into a pulsing signal. They are composed of 2 components: frequency and duty cycle. PWM frequency dictates how long it takes to complete a single cycle and how quickly it fluctuates from high to low. The cycle determines how long a signal stays high out of the total period. Finally, Serial, Serial communication is used to receive and transmit data between the Arduino board and another serial device.

Principles:

For our robotic prosthetic, we decided to do something reminiscent of a pulley system and flexor and extensor tendons to move our robotic hand. We will have strings throughout the palm and fingers which are attached to the servos and are thus able to move. The hand itself reflects Newton's third law of motion, where it states that for every action (or force) in nature there is then an equal and opposite reaction that occurs. If object A exerts a force onto object B, object B also exerts an equal and opposite force back onto object A. In other words, forces result from interactions. This principle is what guides the hand in a way when it comes to the pulley system or tendons, as we pull one string and put force, the finger bends, and pull the other to straighten the finger. This is a relationship with the string and finger, object A and B.

Robotic Prosthetics:

Robotic prosthetics, also known as bionic or robotic limbs, are designed to replicate natural movement and provide enhanced functionality for individuals who had lost their limbs, such as their arm. The development and manufacturing of robotic prosthetics involve advanced technology and engineering. But how are robotic hands made in the first place? In the start, people often start out creating a human-like hand using a 3D printed plastic skeleton or bone structure of sorts, and also soft, moulded silicone material. Multiple sensors may be incorporated into the hand depending on if they only want to mimic functionality and movements, or if the manufacturer has plans to mimic other parts of the hand as well. For example, to mimic the way hands feel pressure, flexible pressure sensors are often applied to the hand’s palm and fingers. This may also be used as of recently in modern technology and prevents objects from slipping out of grasp with just wrist movements. Making it so a lot of parts of the robotic hand don't have to be moved at once. Gyroscopes or Accelerometers may also be used to detect movement and positions. Finally, Electromyography sensors (EMG sensors) may be used to detect electrical signals from their muscles, which allows users to control the prosthetic based on their muscle activity. High-Strength, lightweight materials such as carbon fibre or titanium are commonly used as material for constructing robotic prosthetics. Though for 3d printing, materials like Nylon for its strength and flexibility, Resin for its high-resolution and smooth printing, Acrylonitrile butadiene styrene (ABS) for its durability and its impact-resistance, and also Polylactic Acid (PLA) for its biodegradability and also being lightweight. But one more, which is also the one we opted for, is PETG for its mechanical strength, thermal resistance, and is even more resilient and stronger than PLA. After the construction of the robotic prosthetic, it is often put through clinical trials and tests to see the liability, and functionality of the hand and if it really is fit to be used as a prosthetic.

Variables

Variables

Controlled Variable: The controlled variables for each trial would be the size of each prosthetic and the materials used for the grip and the rest of the hand.

Manipulated Variable: The manipulated variable is the dimensions and shape of the object needed to be held.

Responding Variable: How well a robotic prosthetic can grip and hold certain objects.

Uncontrolled Variable: After multiple usages, the material and prosthetic may not be as smooth and efficient compared to when it was created.

Procedure

- Open up the Arduino IDE software and install our libraries. Because we are coding the PCA9

685 servo driver first, I will install the AdaFruit Servo Driver Library. This allows the PWM sequence to be installed into our circuit, without having to code it ourselves.

- The next step is to define the minimum and maximum pulse length for our servos.

- Next, define how many servo motors we will be using.

- Now, I will be controlling the amount of steps the servo will take. I will start

from 0 degrees (SERVOMIN) and go to 180 degrees (SERVOMAX). Now I need to move it back to 0 degrees. I will create a delay so it isn't an instant movement, and then I will start from SERVOMAX and go to SERVOMIN.

- The final step would be to test our code with the servos, we did this multiple times until we were sure everything was working properly.

__________________________________________________________________________________________________________________

- After brainstorming on how we wanted the prosthetic to work, we implemented our thoughts onto our modelling software tinkercad, which is an online modelling software which allows for advanced models even with basic principles and is an intermediate software friendly to those who have prior knowledge on modelling. During this process, we purchased all of the materials.

- Once the model was completed, we printed it locally from a 3d printing service.

- When the model was received, we had to construct it.

- First, we had to join the finger together. We put the elastic bands in the hole, and created tension with an aluminium rod.

- Next, we tied string on the back and front of the fingers, feeding it through the holes in the palm to our servo pulley system.

- We attached the strings to each of the pulleys, and repeated this process for the other fingers.

- Now, after constructing the prosthetic, we will conduct our experiment. During the three trials, we will focus on 2 main criteria:

- Mobility

- Grip

This was done during the course of the 3 trials. Once completed, we will collect our data and compare it to a human hand. This data will then be used to create our final conclusion.

Observations

Some things I observed in this experiment were that as it was holding the object, it would eventually start to slowly lose its grip. For example, though it could hold the Light & Small object toward the 60 second limit with ease and likely for much longer, when it held the Medium & Moderate object it tended to lose its grip around the 45-50 second mark. The same thing happened with the Heavy & Large object, it began to lose its grip around the 30-35 second mark. It then quickly lost its grip and the object had dropped for every other Medium and Heavy object trial. The reason it loses grip is comparable to gripping a basketball or other spherical object with your hand, it's not only about the the ability to grip well itself, but also mainly having large enough hands to hold the ball comfortably and have large enough fingers to not lose grip or tire out as fast. In conclusion, our robotic hand demonstrated the ability to grip onto both small to large objects for an extended period of time, however the robotic hand did not exceed the abilities of a human hand due to the limited amount of movement and functions. Though, being large was not as much of a problem for our new hand, but more so how slippery the hand seemed, especially the fingertips. For the human graph, it constantly held for the maximum amount of time/limit that was applied, 60 seconds. This is because the human hand had a better grip on the object, and the fingers were somewhat thinner, and also longer to wrap around the objects.

Analysis

People may be interested in our results and project as it reflects on amputees and their daily struggles. Studies and efforts to not only improve quality of life but also increase the efficiency of robotic prosthetics and alleviate pain or uncomfort has only recently arisen. Before, many prosthetic limbs were based on use, not comfort, or giving the ability to feel things such as pressure on your hand, or heat. For hands especially, moving fingers or wrists could be tough with a prosthetic hand and tiring as they would have to tense up in a way in order for the electromyographic sensors (EMG sensor) and such to move hands, but recently electroencephalographic sensors (EEG sensors) have been beginning to replace electromyographic sensors (EMG sensors). There are lots of amputees, whether it was from an accident, an external source or weather conditions such as frostbite, or something else. Many people are in need of prosthetics, and robotic prosthetics not only allow them to regain crucial abilities that will help them in their life and re-establish parts of their body.

Conclusion

Overall this experiment was a success in some ways, even though we made many mistakes that limit the hands potential and ability, we still created a working hand that could grasp specific objects comfortably and could easily move its fingers. Our hypothesis was right as a hand could hold crumpled paper, an apple, or a metal water bottle for much longer with less degree of difficulty then the robotic hand would. Though it works it is still somewhat rigid and can't hold many objects for a long time. This is seen with the Heavy & Large objects trials especially.

Application

People may be interested in our results and project as it reflects on amputees and their daily struggles. Studies and efforts to not only improve quality of life but also increase the efficiency of robotic prosthetics and alleviate pain or uncomfort has only recently arisen. Before, many prosthetic limbs were based on use, not comfort, or giving the ability to feel things such as pressure on your hand, or heat. For hands especially, moving fingers or wrists could be tough with a prosthetic hand and tiring as they would have to tense up in a way in order for the electromyographic sensors (EMG sensor) and such to move hands, but recently electroencephalographic sensors (EEG sensors) have been beginning to replace electromyographic sensors (EMG sensors). There are lots of amputees, whether it was from an accident, an external source or weather conditions such as frostbite, or something else. Many people are in need of prosthetics, and robotic prosthetics not only allow them to regain crucial abilities that will help them in their life and re-establish parts of their body.

Sources Of Error

There were a lot of unprecedented errors that had come up with our experiment.

- One large oversight was the thumb, all fingers could comfortably bend and straighten. But the thumb could not rotate to grab cylindrical objects such as water bottles.

- This was a huge oversight and held the hand back quite a bit because it could not wrap around objects and was held back in use quite a bit because of it. Instead of rotating it would just be blocked by the object.

- Another was that we only had two phalanges that could bend, and not three, so the fingertips/distal phalanges were rigid and did not have much leeway to properly grasp objects.

- The grasp was awkward and stuck. When you grab a water bottle, you are bending your distal phalanges. But when you grab something thin like paper or a dollar bill, your distal phalanges are bent less and are more flat. So because we did not have control over the bending of the distal phalanges, some objects could not be grabbed efficiently.

Citations

References

Arduino Uno Pinout, Specifications, Pin Configuration & Programming. (2021, July 19). Components101. Retrieved December 18, 2024, from https://components101.com/microcontrollers/arduino-uno

Bones of the Hand - Carpals - Metacarpals - Phalanges. (n.d.). TeachMeAnatomy. Retrieved December 23, 2024, from https://teachmeanatomy.info/upper-limb/bones/bones-of-the-hand-carpals-metacarpals-and-phalanges/

Chu, J. (2021, August 16). Inflatable robotic hand gives amputees real-time tactile control. MIT News. Retrieved December 30, 2024, from https://news.mit.edu/2021/inflatable-robotic-hand-tactile-0816

Dunai, L. (2020, December 28). Sensors | Free Full-Text | Human Hand Anatomy-Based Prosthetic Hand. MDPI. Retrieved January 6, 2024, from https://www.mdpi.com/1424-8220/21/1/137

How Do Robotic Prostheses Work? – Human Technology Prosthetics and Orthotics. (n.d.). Human Technology Prosthetics and Orthotics. Retrieved January 7, 2024, from https://humantechpando.com/how-do-robotic-prostheses-work/

Padavic, K. (2023, April 12). Soft robot hand learns how to avoid butter fingers. New Scientist. Retrieved January 11, 2024, from https://www.newscientist.com/article/2368541-soft-robot-hand-learns-how-to-avoid-butter-fingers/

Zait, A. (2018, April 22). The Full Arduino Uno Pinout Guide [including diagram]. Circuito.io. Retrieved January 16, 2024, from https://www.circuito.io/blog/arduino-uno-pinout/

Acknowledgement

We would like to recognise and discern the contributions of both our parents, who aided financially and provided support for this experiment. Also our teachers at the school who aided us in polishing, developing, and encouraging our project to be the best it can be and helping us refine the project. Also guiding us and answering questions we may have had.