Bike Gearing and Gearing Ratios

Grade 5

Presentation

No video provided

Hypothesis

If the gearing is at maximum efficiency then the wheels will turn heist speed and least amount of energy

Research

Wheels

“Bicycles operate via a gear that the operator moves via the pedals. The gear connects a chain to the wheels. Thus, the wheels turn when the pedals are turned. The amount of energy the operator needs to exert to turn the wheels of a bicycle is determined by two things: the diameter of the bicycle wheels and the gears. You could have a bicycle with a very large wheel (like a penny-farthing bicycle) so that one turn of the pedals turns the wheel one time, if your wheel is 53-inches in diameter and it rotates once, the bicycle moves a distance equal to the circumference of the wheel: 166-inches!” (Beaton, 2025)

So this means that there are many parts to a bike and different gear ratios between the front and back. it will affect the speed and efficiency of the bike so it will take less energy for a different speed.

“There are two main types of tires, those made of metal and those made of rubber. Railroad cars, which run on smooth steel rails, use iron or steel tires for low rolling resistance. The metal tire is basically a flat hoop fitted tightly over the exterior of the wheel. Besides low rolling resistance, its other attributes are strength, durability, and resistance to wear.

Free-moving vehicles such as automobiles, trucks, buses, bicycles, and airplanes need more friction to turn, climb, accelerate, and brake, so these vehicles use rubber tires, which provide both high friction and some cushioning ability”(firestone,2024)

So this means because the wheels on a bike are rubber thay have more resistance to grip the trail better but if bikes had metal tiers thay would roll a lot faster on a track but it would be really hard to pedal on a trail that was dirt.

“Bicycle tires come in a bewildering variety of sizes. To make matters worse, in the early days of cycling, every country that manufactured bicycles developed its own system of marking the sizes. These different national sizing,”(Round 2025).

There are a lot of different wheel sizes that change the speed so that the smaller the wheel the easier to accelerate but harder to maintain a faster speed and bigger wheels.

Gears

“Often, there are two different-sized gears that are linked together. The smaller gear is called the driver gear. The larger gear turns when the driver gear turns. Because the driver gear is smaller, it turns twice or three times as fast as the larger gear. These two linked gears turn together and end up activating an engine,” (Nice, K., Hall, K., & Brain, M. (n.d.)).

A lot of times there are two different gears the smaller is called the driver gear and the bigger is the gear that gets turned if the smaller gear is halve the size it turns twice as fast as the smaller gear.

“Gears can change the speed, torque, and direction of a power source. For example, in a bicycle, gears help you adjust the effort needed to pedal depending on the terrain,” (Nice, K., Hall, K., & Brain, M. (n.d.)).

This means that the gear size changes the speed and efficiency and how easy it is to peddle.

Common types of gears include spur gears, which have straight teeth and are used in simple machines; helical gears, which have angled teeth for smoother operation; and bevel gears, which are used to change the direction of motion.” (Nice, K., Hall, K., & Brain, M. (n.d.)).

Bikes have spur gears because then the chain can fit on to the gear without it slipping off the gear and the bike geting de chaind.

Friction

“Friction is the force that opposes motion between any surfaces that are in contact. There are four types of friction: static, sliding, rolling, and fluid friction. Static, sliding, and rolling friction occur between solid surfaces. Fluid friction occurs in liquids and gases,” (Brainard, 2024).

Any surface hase friction even if it is a liquid or gas but static,sliding and rolling friction happen on solid forces while fluid friction happens on liquids or gasses.

“Rolling friction is friction that acts on objects when they are rolling over a surface. For example, as a soccer ball rolls along the ground, it will come to a stop because the rolling friction acts in the opposite direction to the motion of the ball. Rolling friction is much weaker than sliding friction or static friction.” (Brainard, 2024).

Rolling friction is the friction that happens when a tire from a bike is rolling on the ground and it is why we have to peddle.

“Rolling friction is a force resisting the motion, which arises when a ball, tire, or wheel surface rolls on a counter surface. Nevertheless, a rolling body may be of an irregular outline such as boulders or pebbles. Irreversibility in the deformation of contacting materials can be also considered as one of the sources of rolling friction,” (Abdelbary, 2023).

Even an object that is irregular can have rolling friction.

Cassettes

“The cassette is the main element which, together with a set of other components, allows the transmission to change its gear ratio. It is made of a plurality of packed sprockets which are fixed on the cassette support,” (Zahar, 2021).

The cassette is the part of the bike that changes the gear ratios to change speed.

“[The] cyclist selects the desired gear ratio by actuating a device located on the bicycle handlebar, which then actuates a device which sits below the cassette, which derails the chain to the needed position [5,6]. Since the sprockets need to have a well-defined distance between them, a plastic or metallic spacer is used. In recent years, in order to save weight and to make stiffer components, a number of sprockets are being manufactured as a unique solid part. This brings a weight advantage but it removes the cyclist’s ability to customize the combination of the used teeth. A few considerations on the effects of lateral shifting the chain will be made at,” (Zahar, 2021).

The changing of the gear ratio takes multiple parts that have to work together to change ratios.

“Similar to road cassettes, mountain bike cassettes have also increased in size as technology has progressed. Mountain bike cassettes can be found in much bigger ranges with bigger jumps between gears, this is because of the terrain and conditions that mountain bikes are used in compared to road bikes. A lot of mountain bikes now have only one chainring on their chainsets. Due to only having one chainring the cassette needs to have an even bigger range – some mountain bike cassettes are 10-52!” (Bicycle Maintenance Guide, 2023).

Mountain bike cassettes have a lot of a bigger range of gears they can go from 10 teeth to 50 teeth and they also can be found with big jumps from gears to gears

Variables

Manipulated variable wheel gear size.

Responding variable outcome speed on speedometer

controled variables same front gear, same drill and batery, same two speedometer, same chain.

Procedure

- Drill a hole the same size as the bearing at one end of the peic of wood

- Put a bearing into the hole in the block of wood so it spins freely

- Put a shaft in the bearing (make sure it spins freely)

- Connect the center of one gear to the center of the shaft

- Drill a hole in the opposite end of the wood with a drill bit that fits the shaft

- Mount a wheel onto another shaft in the same piece of long wood but at the opposite end.

- Instal cassette onto the wheel.

- Wrap the chain around the single gear in the front and one of the gears in the cassette on the wheel in the back

- Connect the two ends of the chain together with tools needed

- Tighten the chain as tight as you can then add two links of deflection

- Instal the speedometer according to the instructions that came with the speedometer

- Attach a drill to the single gear and shaft in the front

- Turn the drill onto low setting but with full speed of the setting

- Let the drill run until the speedometer stops changing speeds and has a sdedy high speed

- Record the top stable speed of the speedometer

- Turn of the drill and let the wheel come to a full stop

- Repeat steps 10 ,11,12,and 13 four more times

- Move the chain to the next gear on the wheel

- Repeat steps 10,11,12,and 13 five times

- Repeat steps 15 and 16 for the remaining gears

see atacments for experimental set up pictures.

Observations

|

Gear size and ratio compared to wheel speed |

|||||||||||||||||

| Front Gear Size (teeth) | Rear Gear Size (teeth) | Gear Ratio | |||||||||||||||

| 24 | 13 | 24:13 | |||||||||||||||

| 24 | 15 | 8:5 | |||||||||||||||

| 24 | 17 | 24:17 | |||||||||||||||

| 24 | 19 | 24:19 | |||||||||||||||

| 24 | 21 | 8:7 | |||||||||||||||

| 24 | 24 | 1:1 | |||||||||||||||

| 24 | 28 | 6:7 | |||||||||||||||

| Wheel | Input Gear | Ratio | Wheel | Input Gear | Ratio | Wheel | Input Gear | Ratio | Wheel | Input Gear | Ratio | Ratio | |||||

| Gears | 28 | 24 | 0.86 | 24 | 24 | 1.00 | 21 | 24 | 1.14 | 19 | 24 | 1.26 | 0.86 | 1.00 | 1.14 | 1.26 | |

| speed 1 | 24.7 | 28.7 | 0.86 | 22.5 | 22.5 | 1.00 | 10.7 | 5 | 2.14 | 29.6 | 20.7 | 1.43 | 0.86 | 1.00 | 1.14 | 1.26 | |

| speed 2 | 24.9 | 28.7 | 0.87 | 29.6 | 29.6 | 1.00 | 7.7 | 3.9 | 1.97 | 29.6 | 20.7 | 1.43 | 0.86 | 1.00 | 1.14 | 1.26 | |

| speed 3 | 18.7 | 21.8 | 0.86 | 19.3 | 19.3 | 1.00 | 24.3 | 21.3 | 1.14 | 26.1 | 20.4 | 1.28 | 0.86 | 1.00 | 1.14 | 1.26 | |

| speed 4 | 24.9 | 28.7 | 0.87 | 26.3 | 26.3 | 1.00 | 35.1 | 31.5 | 1.11 | 26.6 | 20.4 | 1.30 | 0.86 | 1.00 | 1.14 | 1.26 | |

| speed 5 | 26.8 | 31.5 | 0.85 | 29.3 | 29.3 | 1.00 | 36.5 | 32.3 | 1.13 | 26.6 | 20.4 | 1.30 | 0.86 | 1.00 | 1.14 | 1.26 | |

| speed 6 | 29.3 | 33.8 | 0.87 | 30.6 | 30.5 | 1.00 | 36.5 | 30.9 | 1.18 | 25.1 | 19 | 1.32 | 0.86 | 1.00 | 1.14 | 1.26 | |

| speed 7 | 18.9 | 22 | 0.86 | 33.8 | 33.8 | 1.00 | 28.4 | 31.6 | 0.90 | 24.9 | 19.1 | 1.30 | 0.86 | 1.00 | 1.14 | 1.26 | |

| speed 8 | 24.7 | 28.7 | 0.86 | 23.1 | 31.6 | 0.73 | 24.9 | 19.6 | 1.27 | 0.86 | 1.00 | 1.14 | 1.26 | ||||

| Average | #REF! | #REF! | 0.86 | 1.00 | 1.14 | 1.26 | |||||||||||

| speed 9 | 24.1 | 20.9 | 1.15 | 30.6 | 24.3 | 1.26 | 0.86 | 1.00 | 1.14 | 1.26 |

Analysis

Results

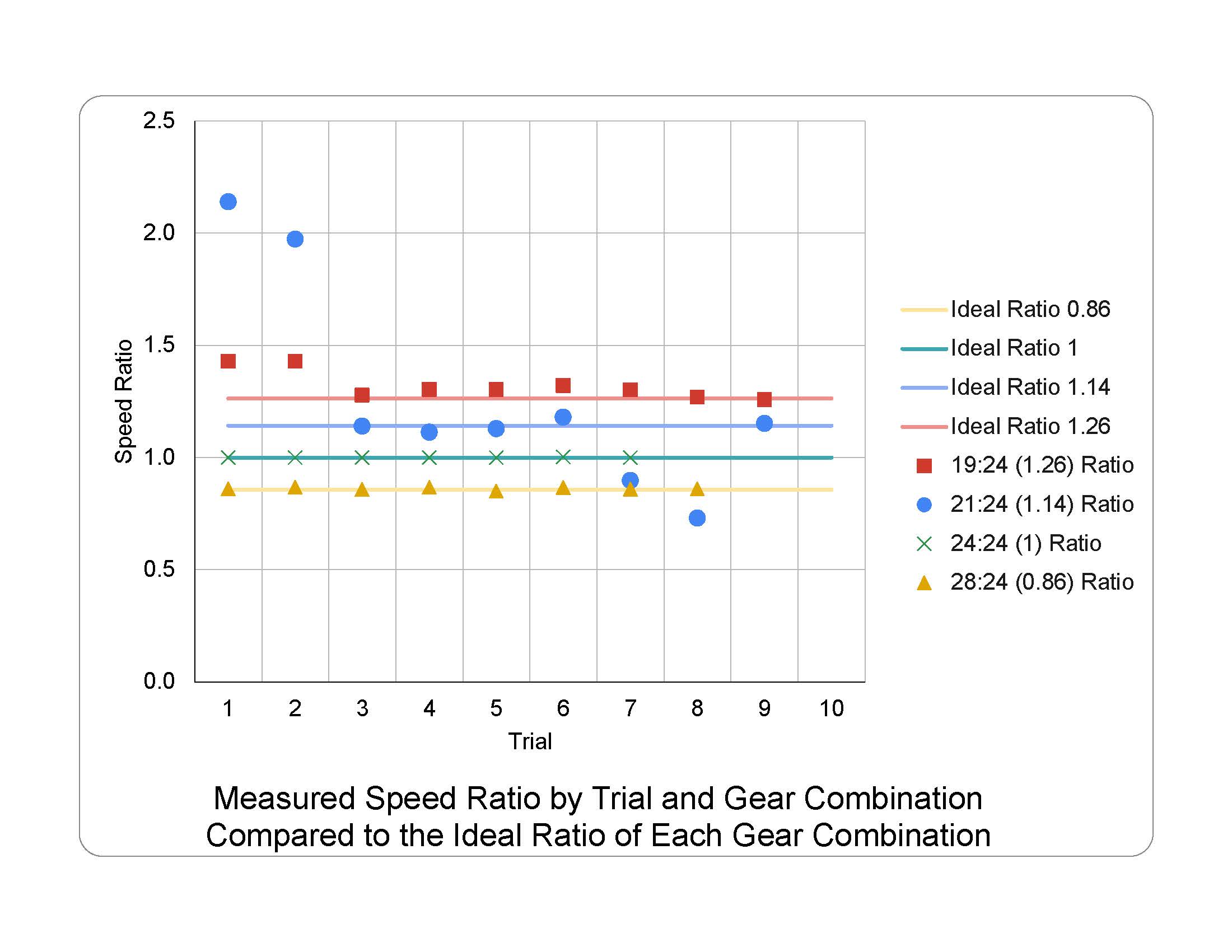

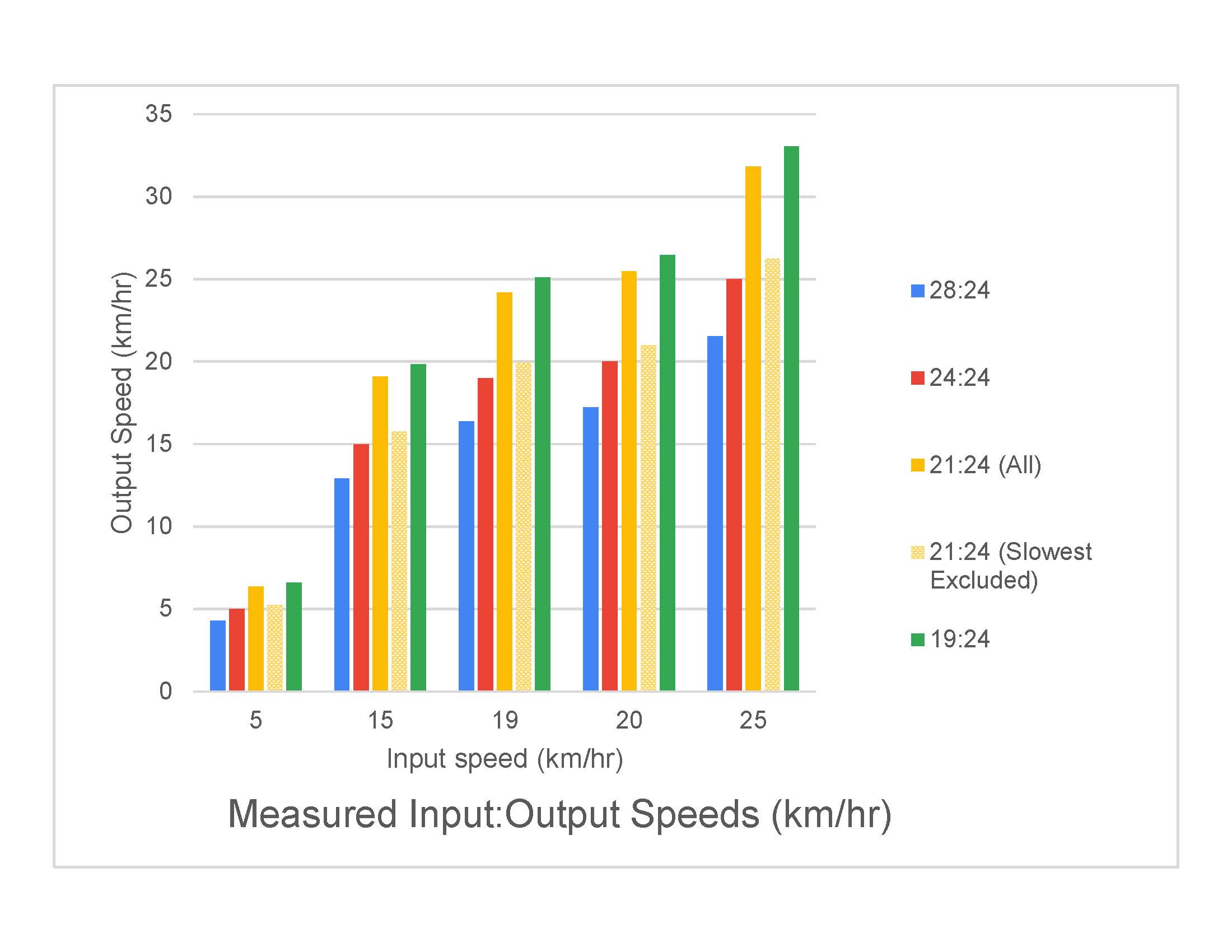

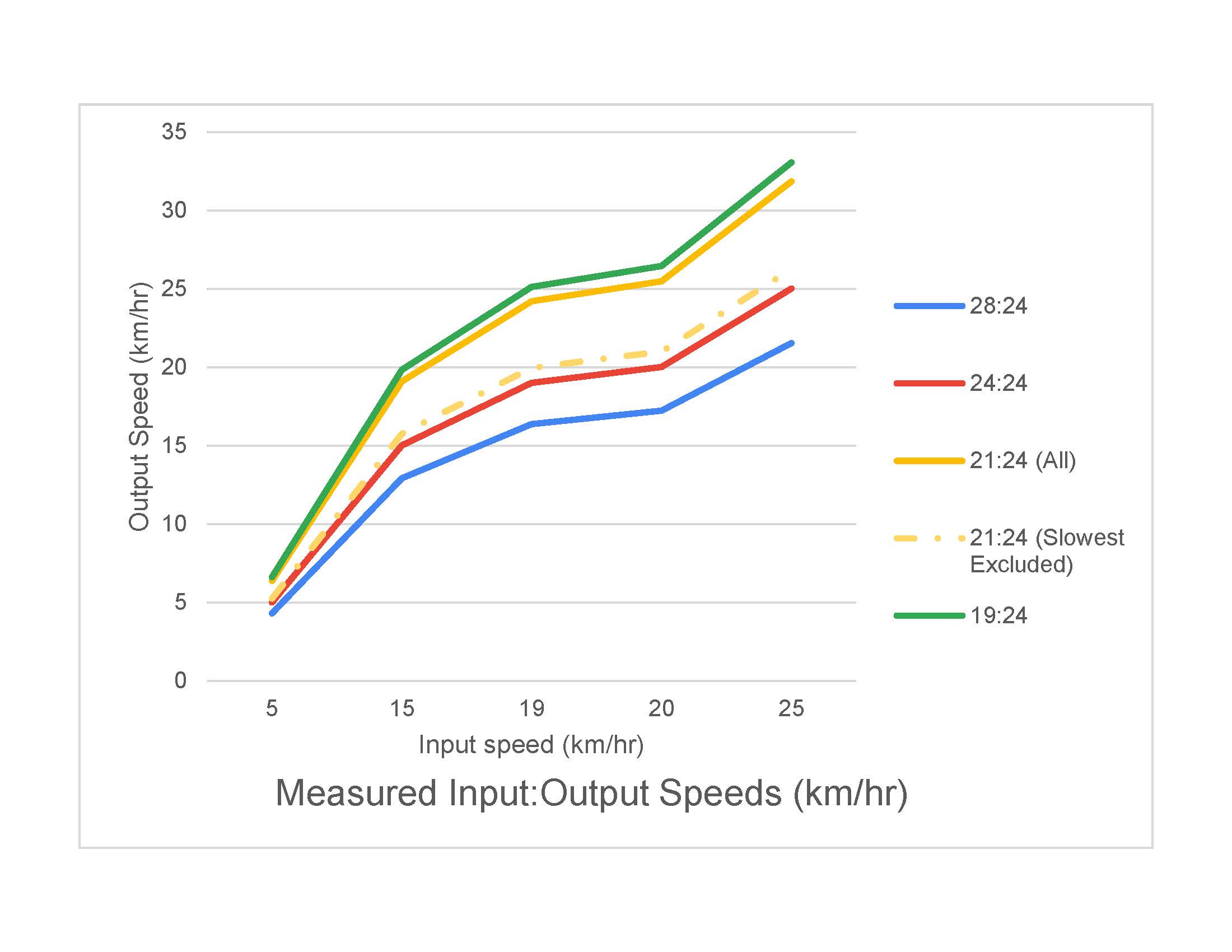

In this experiment I studied the speed and efficiency of different size gears and how they affected energy loss. I tested how the gear size changed the outcome speed thar for if you have a gear that has less outcome speed you will have more energy loss (figure 1 and 2) I found that all of the test except 2 of the tests were close to the ideal speed ratios (0.86,1.00,1.14,1.26) and 2 were not close and they were way off the two blue dots way up near the 2.00 (figure 3).I found that

the smaller gear , so In my case 19 teeth the higher the output speed and the bigger the gear the less output speed and more energy loss you get. so in my case 28 teeth.

Conclusion

Conclusion

I chose my science fair project because I wanted to know if it would be faster to have a smaller gear in the back while riding then having a bigger gear in the back while riding and because my brother and I are very big bikers so in races it would help increase my speed and efficiency.

My hypothesis was correct if the gearing is at maximum efficiency then the wheel will turn at the highest speed . because in my data I fond out that The smaller the gear (19 teeth) the faster output you get for the amount of speed you put in( Fig 1 and 2). The gear in the front of my machine stayed the same while the gear in the back changed gear sizes (28,24,21,19) to get the outcome I got. I think I got the results I got Because of how me and my dad set up my project to run and because we use the drill instead of hand cranks it was more accurate when you took out the data of the speedometer with a phone to take pictures And if we'd use different gears like a 52 tooth a 62 and a 82 tooth instead of 28,24,21,19 tooth it would have had a different outcome which would change my data and graphs and maybe a totally different project outcome using Excel also got the data into the format in graphs that we wanted that we couldn't do on google sheets.

We got 2 unexpected results from the tests when there was a very off ratio ( two blue dots fig 3) which changed how we did our data analysis and changed what the graphs and data we got. First one my experiment we built the parts to the build to create the data that we got this connects to my project because it tells you what gears Change the speed outcome to be higher or lower and because my scientific question was what gearing is best for Speed and efficiency it also gave us the data we needed for efficiency in gearing. I learned the smaller the gear the faster the tire spins and you have more outcome then you have a more efficient gear set up. and relation to the ratios and that if I were to have changed the front gear I would have gotten way different speed outcomes so if we made the front gear bigger all the ratios would be higher and probably would change the averages that I got. Overall the answer to my scientific question is the fastest gear is the smallest gear in the back and biggest in the front and the smaller gear also gives you the highest outcome for the less income so it has the best efficiency for riding on flats or Downs but on ups you would most likely use a smaller gear that has less outcome but is easier to spin .

Application

This applies to the real world because you could apply this to cars and motorcycles. And if olympians used this work they could have faster times in sprints and distance. This could also make biking a more used sport that would use less gas and decrease global warming and less toxic gases would slowly close the hole in the ozone layer. And decrease the amount of cancer in the world. When I ride in races or in everyday life on my bike it will improve my speed and efficiency. And then I can brag to my brothers when I win in a race. Specifically gears are the things that make a bike run so without knowing is the best you would go slower. Gearing is used in a lot of basic and complicated machines and it applies to them in the same way as it does to bikes.

Sources Of Error

- The chain constantly kept coming off at a higher speed(30-32 km ph) when we speeded up the drill.

- Different amounts of tension on the chain when we changed gears and had to move the wheel.

- The alignment of the magnet and sensor on the wheel would cause the speedometer to read different speeds

- Any drive speed reading taken at a slower speed than the last measurement needed enough time for the wheel to slow down on its free hub so the drive gear was again driving the wheel gear.

Citations

References

(2003). https://www.sciencedirect.com/science/article/abs/pii/S0341816203000195

Abdelbary, A. (2025). Rolling Friction. science direct. https://www.sciencedirect.com/topics/materials-science/rolling-friction#recommended-publications

Beaton, M. B. (2025, january 1). spinning your wheels! ck12. https://flexbooks.ck12.org/cbook/ck-12-basic-algebra-concepts/section/12.1/related/rwa/spinning-your-wheels/?referrer=search

Bicycle Maintenance Guide. (2023, June 9). Bicycle Cassettes – Explained. bike maintenance. https://bicyclemaintenanceguide.com/bike-cassettes-explained/

Brainard, J. (2024, december 5). types of friction. ck12. https://flexbooks.ck12.org/cbook/ck-12-middle-school-physical-science-flexbook-2.0/section/10.5/primary/lesson/types-of-friction-ms-ps/?referrer=search

Brown, S., & Allen, J. (n.d.). Articles about Bicycle Wheels. Sheldon Brown. Retrieved January 9, 2025, from https://www.sheldonbrown.com/wheels.html

Kershaw, J. (2025, january 1). Put the pedal to the metal. ck12.org. https://flexbooks.ck12.org/cbook/ck-12-middle-school-math-concepts-grade-8/section/8.3/related/rwa/put-the-pedal-to-the-metal/?referrer=search

Nice, K., Hall, K., & Brain, M. (n.d.). How Gears Work | HowStuffWorks. Science | HowStuffWorks. Retrieved January 8, 2025, from https://science.howstuffworks.com/transport/engines-equipment/gear.htm

Wheel | Invention, History & Uses. (2024, December 31). Britannica. Retrieved January 7, 2025, from https://www.britannica.com/technology/wheel

Zahar, A. (2020/2021). POLITECNICO DI TORINO. Master of Science in Mechatronic Engineering. https://webthesis.biblio.polito.it/17959/1/tesi.pdf

on/10.5/primary/lesson/types-of-friction-ms-ps/?referrer=search

Acknowledgement

graphs or data the way I wanted it he let me use excel on his computer.he also helped by dying the things I needed. James, my oldest brother, helped inspire me to do this project . Whenever I hadI would like to thank all the people who helped me through this project. First, I would like to thank my mom Janet. She is also my STEAM and science teacher. She helped me with my background research and with all the times I couldn't figure out the computer. And when I was having a bad day. Next I would like to thank my dad. He helped me with building my design to run tests on and because I have a chromebook I couldn't get a question in STEAM and I was on the help list. She would try her very best to help.