The Golden Egg

Grade 8

Presentation

Problem

Dryers waste tons of electricity all year round. Have you ever felt clothes that were just dryed? Were they warm? Well I can tell you that almost certanly they were. Dryers waste tons of electricity during the drying cycles because they only rely on a timer. Occasionaly dryer machines might have a moisture sensor that could impact the running time of the dryer. Most of the time that change affects the consumption of electricity. The moisture sensor is incorrect almost all the time. This is the problem I am trying to solve by creating a device that uses a humidity sensor instead of a moisture sensor which will automaticaly detect when the clothes are dry and notify the user.

Hypothesis:

If I can create a device that can detect when clothes are fully dry then it can save electricity because the device will sense the set amount of humidity when the clothes are dry so it will tell the person(or the dryer) to turn machine off so it will stop using unneccesary electricity.

How a dryer works:

A dryer is a home appliance made to dry the clothing by using heat instead of the “traditional” way of just letting it sit on a drying rack. There are two main types of dryers Vented dryers and Condenser(ventless) dryer.

Vented dryers work by taking air from the inside of the house, heating it up and then pumping it outside. With my experiment i used this kind of dryer. It is mostly used in houses that have an easy way to put the air exaust pipe outside.

Vented dryers work by taking air from the inside of the house, heating it up and then pumping it outside. With my experiment i used this kind of dryer. It is mostly used in houses that have an easy way to put the air exaust pipe outside.

This is a condenser dryer. A condenser dryer work by reusing the air already in the dryer, heating it up and then after some time it goes through a condenser which removes most of the water vapour in the air, then it heat the air back up and runs in through the machine again. This type of dryer is mostly used in apartments where there is no easy acces outside to pump air like a vented dtyer.

How the device works:

My device works by having a capacitive humidity sensor(SHT3X) measure the humidity inside of the dryer on a constant basis with a set amount of time between mesurments that results in more accurate predictions on when the clothes in the dryer are completely dry.

My sensor, the SHT3X, is a capacitive humidity sensor(sometimes it is also called a relative humidity sensor). It works by consisting of two metal electrode layers between a dielectric (non-conductive) material. The dielectric film inside the capacitive humidity sensor attracts and absorbs moisture from the surrounding air. Once the moisture contacts the electrodes a voltage change occurs.

When moisture is absent, the capacitive ability of the sensor is determined by the dielectric constant (the dielectric constant also known as relative permittivity is the measurement of how much a certain material can store electrical charge) . As the humidity changes in the surrounding air the dielectric layer absorbs and releases water vapor. As a result the electrical capacitive ability of the sensor changes(hence the name "capacitive").

As an example the dielectric constant of water at room temperature is 80, which is significantly larger than the dielectric constant of the dielectric material used inside of the sensor. When the dielectric material absorbs water vapor from the surrounding air because the water particles that are now absorbed by the dielectric layer have a much higher relative permittivity which means they increase the dielectric constant of the dielectric layer, an increase in the dielectric constant occurs, increasing the capacitive ability of the humidity sensor.

The change in the dielectric constant is directly proportional to the relative humidity(the maximum amount of water vapor that air could hold at a given temperature), therefore by measuring the electrical current given by the dielectric constant that changes I could calculate and turn those changes into humidity readings that I used.

The device it self worked by reading the data that the sensor was giving it and when it reached a certaint amount of water vapour in the air(which was the range from 25-35%) it sent me a signal via wifi, recorded the time from the point of it being turned on to the point of it turning off. That is the data I used in my graphs. The set amount of water vapour in the air had to be stable for about two miniutes before the device could positively turn off and send me a signal. Those two miniutes are there to ensure that the clothes are dry and that the humidity sensor did not pickup any air with a lower humidity that just entered the dryer.

Method

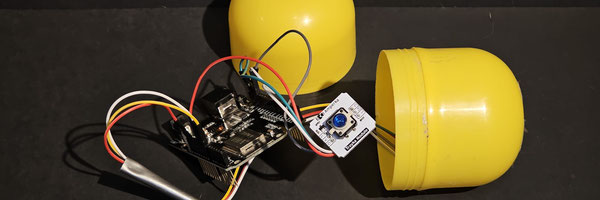

To create a device I first used materials that I already had. Then I also reasearched on what motherboard and batteries to use for the device. I settled on the ESP32 and a double lithium battery holder as the power source. I chose the ESP32 because it has a built in wifi module that I used to connect the device with the app I made that sends a notification as soon as it recieves a signal from the sensor. It also has a 32-bit processor(hence the name ESP32) and approximately 520 KiB RAM, which lets me store and use the code very fast and effectively. The dual lithium battery holder which is connectable to the motherboardwas my choice because of its durability and its “shield” feature that doesn't let the batteries supply too much power preventing a fire or even an explosion during the drying procces. The outer shell of the device was a yellow kinder egg capsule. This is where I got the idea of the project name - the golden egg. This capsule withstood the temperatures of up to 50 degrees celcius inside of the drying machine. It was also impermeable and had enough space to fit all of the compartments of my device inside of it without cramping everything together. To start the proccess of my code I used a button. The main component of my device was of cource the humidity sensor which I talked about earlier.

For the app connected to my device I used the help of AI(ChatGPT) to help me create and understand the procces of making a mobile app. It also helped me debug some of the code thast was not working. For the code of the device itself that was completely made by me and revisioned by a specialist of the field- a veteran coder Dmitry Sadakov, he is now a international teacher for coding on multiple languages. To run the app I used AndroidMachine as it is one of the most commonly used softwares for the job.

All of the clothes were evenly washed on the same cycle, using the same laundry producs before all of the tests. The amount of clothes was also fairly the same filling the dryer by about 75% each time.

To start the test I had to load all of the clothes into the dryer, then i had to press a button in the device, seal it up with duct tape and then put it in with the clothes and start the dryer. Then I would have the app running on my phone and I would time until i got the notification from the device. Then I would go and check if it was correct.

There was only one outlier during the testing of the device. That outlier happed on the last and eight test of the device. I did not properly seal the "egg" which in result caused the motherboard to break. I had spares to completely duplicate the device.

Analysis

Table of "Normally" Dried Clothes and Time Recorded by the Device:

Test 1 Test 2 Test 3 Test 4 Test 5 Test 6 Test 7

Normally(Miniutes) 120 124 118 131 125 122 124

Device(Miniutes) 93 102 97 120 114 110 103

As we can see from the table above the device showed consistent results of recording the time of the clothes being completely dry. The average time of the time recorded by the device being shorter than the normal cycle was about 15%. That 15% can be corelated to an average of close to 18-20 miniutes saved each drying cycle.

Now to calculate the electricity and money saved. The energy consumption of my dryer unit is 2.5 kWh per hour. The current cost of 1 kWh is approximately 0.09$ + delivery fee which is about 0.03$ per kWh. If we multiply it all together we get 60-70 cents per each drying cycle using the same model as me.

If we account that with the device that the drying was 15% faster, we can calculate that we will save 10-25 cents on each load. Depending on the usage of the dryer the amount saved per year will vary. I recorded my familys usage of the dryer over the course of this years Science Fair(about 4 months) and applied it as an example here, I calculated if my family(a standart family of 4) will continue using the dryer at the same rate we could possibly save 30-40$ each year.

We can use this data to form a conclusion of how much electricity will be saved and where it can be used instead.

Conclusion

My device worked in achieving the goal i set it to do, which was to automatically detecting when clothes are fully dry and then notifying the user(in this case me). The device showed steady results of recording the time of the clothes being dry compared to the finish time of the drying cycle was 20% shorter. I expected this kind of outcome based on my backround research that shows that moisture sensors are not always correct in their readings and will in most cases affect the time in a negative way increasing the electricity consumption thus wasting energy. This project is also an extension of my last years project, so basing my hypothesis and infrences on that data it proved to be correct. Most people that use dryers dont mind the waste of electricity, but if we scale things up to every household in Calgary(which is about 220,000) then we use the approximate amount saved anually in one household(about 30-40$ saved) then we get a whoping 8 million dollars! That is only Calgary and thats not even counting the countless buisnesses specializing in cleaning clothes for example laundromats. All of that electricity could power approximately two thousand homes for a year, two million houses for a day, street lights in a city like calgary for half a year. Thats only the electricity saved from Calgary, imagine what would it be on a bigger scale.

Citations

https://howtomechatronics.com/tutorials/arduino/arduino-ds3231-real-time-clock-tutorial/

https://lastminuteengineers.com/sht31-temperature-humidity-sensor-arduino-tutorial/

https://www.whirlpool.ca/en_ca/blog/washers-and-dryers/how-many-kwh-does-a-dryer-use.htm

https://docs.arduino.cc/built-in-examples/sensors/Ping

https://www.arduino.cc/reference/en/libraries/ds3231/

https://forum.arduino.cc/t/how-to-fix-all-lcd-problems-read-this/100051

https://www1.enmax.com/electricity-and-natural-gas/easymax

https://howtomechatronics.com/tutorials/arduino/arduino-ds3231-real-time-clock-tutorial/

https://lastminuteengineers.com/sht31-temperature-humidity-sensor-arduino-tutorial/

https://www.whirlpool.ca/en_ca/blog/washers-and-dryers/how-many-kwh-does-a-dryer-use.html

https://charts.livegap.com/v2/app.php?lan=en&gallery=line

https://www.consumerreports.org/appliances/laundry/energy-saving-laundry-tips-a9261296729/

https://home.howstuffworks.com/dryer.htm

https://www.consumerreports.org/appliances/laundry/energy-saving-laundry-tips-a9261296729/

https://www.techtarget.com/whatis/definition/sensor

https://learn.sparkfun.com/tutorials/what-is-electricity/all

https://ars.repair/dryer-repair/how-to-replace-a-dryers-moisture-sensor/

https://atlas-scientific.com/blog/humidity-sensor-types/#:~:text=Capacitive%20relative%20humidity%20(RH)%20sensors,moisture%20from%20the%20surrounding%20air.

Acknowledgement

I have to give a special thank you to the Science Fair curator at Louis Riel School - Mrs.Davis a huge thank you for this opprotunity and the ability to participate in this years CYSF.

I also need to acknowledge my science teachers Mrs.Rowley and Mrs.Sleiman because they have introduced me to this years Science Fair and have given me lots of feedback on my project.

A person who also helped me is Dmitriy Sadakov, he has been my coding teacher for the past couple of years and has helped me with debugging and partially creating my code template. With him I originaly brainstormed ideas for my project and came up with this.

My dad is also a big part of my support, he helped me with my trifold, helped me with proceding with the project and reminded me to leave time to work on it. He gave me so much support during the project.

I must be thankfull to all the people who read, looked, and talked about my project, gave me advice and supported me.