Advancing Brain-Computer Interface Technology through Innovative Design for Enhanced Human-Machine Interaction

Daniil Tyurin

Grade 10

Presentation

Problem

The creation of Brain-Computer Interfaces (BCIs) represents a groundbreaking frontier in the convergence of neuroscience, technology, and medicine, with a profound impact on healthcare [1], [2], [3]. BCIs offer transformative solutions for curing blindness by directly stimulating the visual cortex and restoring mobility to paraplegics through the interpretation of neural signals. These interfaces also advance brain disease treatment and research by providing real-time insights into neurological disorders and facilitating targeted therapies. Beyond clinical applications, BCIs serve as powerful tools for general neuroscience research, offering unprecedented opportunities to study cognitive processes and enhance cognitive abilities through neurofeedback. The integration of BCIs into medical practice also holds the promise of eliminating or significantly mitigating the limitations imposed by neurological conditions, ushering in a future where healthcare is revolutionized by the seamless integration of the human brain with cutting-edge technology. But despite the transformative potential of BCIs, their current adoption faces challenges rooted in the size, invasiveness, and lack of spatial resolution of existing devices [3]. Additionally, concerns about infection and malfunction further impede accessibility. The technology's decoding capabilities remain limited, affecting the precision of neural signal interpretation. Addressing these challenges, including the need for advanced computational power, is critical for optimizing BCIs and for their widespread acceptance.

Current state of the art BCI technologies exhibit limited capabilities in one or more of several ways, size, damage to the surrounding neural tissue, longevity, capability, safety, and ease of implantation [3]. Microwire based brain computer interfaces are prone to issues such as buckling, limited recording capabilities, damage of the surrounding tissue, and a relatively low longevity [3], [4]. Flexible film sensors are incapable of accurate or large scale detection, localized implants create challenges such as heat distribution and potential damage to the neural tissue, and intravascular means create background noise, hindering the decoding capabilities of the technology. It is for these reasons and more a different approach to the creation of BCIs is proposed. Several hundred microscale neural implants that relay with an external decoder would minimize damage, increase longevity almost indefinitely, increase precision within recording, and create ease within the implantation system itself. The design and creation of such a system of micro scale neural implants is the basis for this project, and if successful, would bridge the gap in accessibility, safety, and capability of BCI technology.

Method

Abstract

This scientific paper introduces an approach to neural activity detection utilizing micro-scale piezoelectric crystals, wherein backscatter ultrasound waves are generated through an external device, and the crystal, deformed by neural tissue voltage, sends back distinct waves indicative of the applied voltage. My proposed methodology involves implanting micro-scale piezoelectric crystals near neural tissue. As neurons generate electrical impulses, the corresponding mechanical vibrations from the piezoelectric crystals induces backscatter ultrasound waves when an external device sends ultrasound signals to the crystal. The paper emphasizes the high sensitivity, spatial resolution, and temporal precision of the proposed approach, surpassing current invasive techniques. The paper also details the creation of piezoelectric crystals with multiple tentacles, each having different electrical resistances. This innovative design enhances spatial detection capabilities, allowing for the differentiation of neural signals based on the unique electrical resistance profiles of the crystal's tentacles.

1.2.Broad Review

Although BCI’s are not a new concept, and their design and implementation dates back to as early as 2010, their safety and capabilities have been severely lacking, especially in comparison with the advancement of other technologies and sciences that further our understanding of things such as material sciences and neurobiology. And as such, with recent advancements within neuroscience, and materials sciences, a new approach to the detection of not only neural activity within the brain, but also within other regions of the nervous system must be presented, which is the purpose of this project. But before even considering the possibility of designing a new system and approach to this problem, previous approaches, systems, materials, and results must first be understood, which is the purpose of this broad literature review, as to solve a problem, the problem must first be understood.

As previously explained, this paper outlines and demonstrates the engineering process in the design, development, and testing of a system of microscale piezoelectric material based crystals, and external sensor devices for the detection of neural activity in not only the brain, but other areas of the nervous system as well. This was proposed as the primary focus of this research based on several factors, including previous background knowledge of several ideas within BCI’s, material science, and neurobiology, and, more specifically microscale piezoelectric materials and ultrasound backscatter, because of the growing necessity for the individual to be more interconnected with the digital world around them, safely, quickly, and reliably. The biggest “selling points”, so to speak, of this project are the predicted safety in both the implantation, and long term use of microscale piezoelectric crystals within biological tissue. While their size, if successfully and functionally properly created, would most certainly distinguish them in safety over other, current state of the art BCI systems, it would also allow for higher density of detection sites in similarly sized areas of neural tissues.

To analyze and explain why it would be beneficial for this system to remain on the microscale, and use ultrasound, in conjunction with piezoelectric crystals, instead of other wireless means of communication, and other material choices that may at first seem simpler, let us first discuss current state of the art BCI’s and their shortcomings.

BCI’s are generally split into two major categories, invasive, and non invasive. Although other categorizations of BCI’s exist, such as chemical sensing, electrically sensing, and so on, let us first look at the primary differences between invasive and non invasive. Invasive BCI systems are just that, an invasive system that breaches the confines of skin and bone to get a higher detailed, more in depth analysis of the brain activity within a certain area. Non-invasive systems on the other hand are systems that generally remain outside of the body, or systems that enter the body through familiar, and previously well repeated means, such as intravascularly. Oftentimes, the preferred methodology for patients, and for individuals who are necessitated by outside circumstance to receive a BCI, is the non-invasive system, due to both its relatively low risk, and its capability to be removed at almost any time if complications were to arise. Invasive BCI’s on the other hand, are the preferred methodology for more accurate, and higher resolution patterns, due to the nature of the applied signals. The sensor is not only closer to the signal that it initially needs to monitor and detect, but it is also more precisely placed in the landscape of the biological tissue, be it that of the brain, or that of other nerves or parts of the nervous system. Most state of the art, or groundbreaking technologies within BCI’s today are invasive in nature, due to several factors, but the primary leading one being that material science and knowledge of scientific principles has not yet caught up with the requirement of accurate detection of tiny electrical impulses deep within tissue, and behind a barrier of bone. Although safer systems for invasive BCI’s are being developed, and it is often those systems that are referred to as groundbreaking, their limiting factors in the nature of the detection, and the accuracy of detection hinders them from being used in neurobiological research when it is often times necessary to detect small activations, rather then detect large areas of simultaneous activation. This is a primary driving factor in the development of micro piezoelectric crystals for neural detection, as on such a small scale, the crystals have the ability to detect activation of only a couple neurons, rather than large chunks of neurons for the cataloging of the activity. Their small size would also make them safer and less invasive then the current system, allowing for unparalleled research into the neural activity of the brain.

Furthermore, the other greatest theoretical benefit for the use of micro scale piezoelectric crystals within the detection of neural activity, is the ability for the crystals to provide a higher resolution image of activation, compared to other methodologies. If the detection of neural activity is thought of as a three dimensional map of the brain, we can with most current state of the art technologies, detect activation on a single planar site, without very much variation of depth within the detection, because the probes cannot be stacked on top of one another, and cannot be placed in high density. Micro scale detection sites, on the other hand, provide the ability to be placed incredibly densely within the brain, but also on top of one another, depth wise. The ultrasound backscatter wave, should also theoretically be much different for each layer of depth, at least in the sense that if it is at least detectable at different intervals, due to the distance, and the speed of travel within the medium, it should be possible to differentiate between the crystals at different depths.

1.3.Biological Background

As this project is an engineering project in nature, with certain elements of physics involved, its primary purpose is still biological, and by that, I mean that the projects main purpose is to advance biological, and mainly, neurobiological sciences by advancing the systems that test and catalog the information of neural tissues, and the brain. As this is the case, and if we consider this project as the design of the tools that measure and analyze biological processes and tissues, then it becomes easier to understand why biological background is required before even the initial design of the project. To create a tool to measure and analyze a phenomenon, primarily the interactions between neurons, and other neural cells, we must first understand the phenomenon thoroughly. With this brief introduction, let us first analyze our primary target, the brain.

The brain is an incredibly complex biological structure within us that regulates our thoughts, our feelings, and our background processes that keep us alive. In its entirety, it is still not fully understood, and may never be fully understood, due to its sheer complexity, and perplexing nature. While we understand approximately what each area of the brain is responsible for, and how, as well as why it functions, we cannot with full certainty be sure of, basically anything about it. The brain, while primarily made up of roughly 60% fat, the other, 40%, is full of functional, and incredibly important neural cells. Further, the brain is divided into large subsections, such as the prefrontal cortex, in accordance with their function, and while these areas are important to understand for the purposes of placement of the microcrystal detection sites, they are not of importance in the understanding of the cellular makeup of the brain, which is the primary interest when creating a device for the measurement of that activity. For our cells of interest are the neurons, and while the brain is composed primarily of two divisions of cells, glial, and neural, neural cells, or neurons are our cell of interest for their primary function. Glial cells provide structure to the brain, and act as assistants to the function of the neurons, and while they do serve an important purpose within the overall function of the brain, neural cells are responsible for thought, and as such, are the cells important in the design of the tools to measure them, to further our understanding of the brain, but to also allow for heightened human-machine interaction. Neurons are an electrically excitable cell that fire electrical signals called action potentials across a neural network, and they communicate with other cells via synapses, which are specialized connections that use amounts of chemical neurotransmitters to pass the electrical signal from the presynaptic neuron to the target cell through the synaptic gap. And, although it is true the process within a neuron the transmits information is not entirely electrical, it is still the primary driving factor behind the passing along of information inside of a neural network, and while systems for the chemical detection of transmission between neurons is in development, and to some extent do exist, this project will focus entirely on the electrical potential and the electrical discharge of a neuron for the detection of its activation. Neurons, are cellular structures just like any other, meaning that they consist primarily out of the same components as any other animal cell, such as the cell membrane, nucleus, and all the other organelles that comprise the primary structure of a cell responsible for many things, such as the maintenance of energy within that cell, although, as a specialized cell neurons do exhibit slightly different structures than ordinary cells. For our purposes, major organelles within the neuron will be excluded from our analysis, due to the fact that they are unnecessary for the understanding of the overall function of the neural cell, in terms of outside electrical activation and stimulation. While they are responsible for these happenings, they are ultimately unimportant and the detection of the activation of a neuron, and we will therefore assume some amount of background knowledge within the organelles of cells and their primary functions. With that being said, let us first analyze a typical neural cell, or rather one of the most common types of neural cells. Neurons are highly specialized for the processing, and the transmission of signals within a neural network, and given their said diversity of function, there exists a wide variety within shape, structure, and positioning within neural cells, and as such the following description of a neural cell is one that is very generalized, and might not apply to every single type of functional neuron. Firstly, within a neuron there exists the soma, and it acts as the primary body of the neuron, it contains the functional organelles of the cell and can range anywhere from five to one-hundred some micrometers in diameter. The soma of the neuron is also intrinsically connected to the detection of activation within a neuron, as it is connected to the cell membrane on which the action potential of the neuron occurs, but this is discussed later Nextly within the overall structure of a neural cell, there exist dendrites, and they are the extensions of the neural cell, similar to branches of a tree, and they are the primary source of input of the neural cell, and for our purposes of the detection of neural activity, will be the primary areas of implantation of the micro crystal, besides of course the axon of the neuron, for the detection of neural activity in surrounding neurons, as communication and activation of a neuron is a two-way process requiring first the initial activated neuron, and secondly the receiving neuron. Finally, there exists the axon, which is a long, fine, cable-like protrusion of the neural cell that has the capability to extend hundreds, if not thousands, or tens of thousands of times the diameter of the soma in its length, and its primary purpose is to carry nerve signals away from the soma. Most types of neurons only have one primary axon, but this axon often branches extensively, enabling the singular length of the axon to communicate with several target cells. The connection between the soma of the neuron and the axon is called the axon hillock, and is oftentimes the most easily electrically excitable part of the neuron, due to its high concentration of sodium channels, which we will discuss in depth later. The furthest part of the axon away from the soma is called the axon terminal, and it contains the synapses of the neuron which allow the communication of the neural cell with other neurons via the use of neurotransmitting chemicals. A basic structure of the neuron can be seen below in figure 1.3.1.

While all of the aforementioned aspects of the neural cell are important to understand within the grand scheme of the neuron, our primary focus is the neuron's ability to transmit signals between cells. This occurrence is due to the neuron producing an electrical action potential along the cell membrane, which as a signal is transmitted and conveyed to other cells via chemical means. Neuron action potentials are a fairly complicated process, and they are the process most valuable to us in the detection of neural activity using a system which relies on electricity for detection, but the process essentially breaks down into five stages. First, before explaining the process of the action potential in depth, it is important to understand the fact that a neuron's membrane, at rest, has a potential, or an electrical charge difference across the cell membrane of the neuron when they are not actively transmitting a signal. At rest, the inside of the neural cell has a negative charge relative to the outside, at around -70mV. This resting potential is maintained by the selective permeability of the cell membrane to different ions, primarily sodium, potassium, and chloride. During the firing of the neuron, and the activation of the process of the firing of the action potential, the neuron firstly experiences depolarization. Depolarization it the neurons ability to temporarily change the membrane potential by selectively opening certain ion channels allowing positive ions, typically of sodium, to flow into the neural cell, and as more sodium ions enter the neuron, it becomes less negative, leaving its resting potential state, and allowing it to transition to the next stage of the action potential process when the depolarization of the neuron reaches a critical maximal threshold of approximately -55mV. Once this critical action potential threshold is reached, voltage-gated sodium channels in the membrane of the neural cell open, causing a sudden influx of positively charged sodium ions into the cell, which causes a sudden, and sharp reversal of the cells membrane potential, forcing the inside of the cell to become more positive than the outside, which is the action potential of the neuron. After reaching the peak of the cells action potential, which can range anywhere from 40mV - 70mV, the membrane potential begins to repolarize to its original resting state, as voltage-gated potassium channels open, potassium ions flow out of the neuron, creating an outward movement of positive charge from the inside of the neuron, restoring the inside of the neuron closer to its original negative state, leading to the fall of the neurons action potential. After this, in some cases, exists the force of hyperpolarization, which is the direct result of the repolarization state of the neuron, in which the membrane of the cell becomes more negative than the resting potential, which is caused due to the over prolonged opening of the potassium channels, or the over prolonged closing of the sodium channels. Following either the period of hyperpolarization, or the more adequate repolarization of the membrane from the action potential of the neuron, comes the refractory period, which is a period of time after the firing of a neuron in which it is incapable of producing another action potential. This period ensures that the action potential travels in one direction along the neuron, and is also a period for the repolarization of the neuron from the hyperpolarization state of the neuron. A graphical representation of the firing of a neuron's action potential can be seen below in figure 1.3.2.

The above graph demonstrates the resting potential of the neuron, and the sudden spike of the neuron's activity, before the climb of its action potential. The y axis is representative of the millivolts of difference within the neuron's membrane, and the x axis is representative of some arbitrary time. The tight side of the graph displays the period of hyperpolarization of the neural membrane, and the neuron's slow flow of positive ions to regulate its overly negative potential, to a more natural resting potential for the cell. The propagation of the action potential, starting with the body of the neuron, and traveling down the axon to transmit a signal is exactly what we are trying to monitor with electrically sensitive monitoring equipment. The propagating action potential through the axon is the indicator of cellular activation, and is exactly the easiest area to detect this electrical activation in. While chemical methodologies for the detection of the activation of the neuron are incredibly interesting for several reasons, their placement would be slightly different, and their measurements would also be slightly different. Now, with a slightly better understanding of the electrical activation of the neural cell, which has not been mentioned yet, but is several orders weaker than the 50mV - 100mV of action potential difference within the membrane of the cell, as it is not directly monitoring the travel of ions through the membrane, and is not directly placed within the membrane. The actual measured signal is much weaker, and is solely from the induced electric field from the action potential, and changes within the membrane potential, we can now begin to understand what we need from the designed system, and how it needs to be achieved.

1.4.The Physics of the Reverse Piezoelectric Effect

Piezoelectricity is the foundational principle behind the basis of this project, and can be summarized as the accumulation of electric charge on the surface of a material resulting from the deformation of the crystal lattice structure of the material. Since it is the materials capability to generate an electric charge on the surface of the material from the materials crystal lattice structure being deformed due to outside stress, the effect relies on the asymmetry within the crystal lattice structure of the material to produce the charge. The word piezoelectricity itself means electricity resulting from pressure, and is derived from ancient Greek. The effect is the result of the electromechanical interaction between the mechanical and electrical states in a material which exhibits no inversion symmetry, which is the symmetry within the crystal lattice structure of the material. The effect is closely related to the occurrence of electric dipole moments within a set material, and the asymmetry of the crystal lattice structure of the material.The non-centrosymmetric crystal structure, and the distribution of positive and negative charges within within a set unit cell being asymmetrical produces a shift in the charge density of the material when an external mechanical force is applied to the material, and therefore the crystal lattice structure. The mechanical deformation, and the resulting shift of positive and negative charges along the planes of the materials crystal lattice structure, creates displacement regions of the charges, resulting in an electric dipole across the material. The cumulative effect of the electric dipoles across the materials crystal lattice structure, leads the material to the generation of an overall electric polarization, which manifests as an electric field within the material, creating potential difference across the materials surface, creating a voltage potential difference. Figure 1.4.1 demonstrates an example of the type of asymmetry within the charge distribution of the material required for the production of the piezoelectric effect.

The creation of the slight difference within the overall electric charge of the crystal lattice structure on the atomic scale, produces an overall voltage across the materials surface on the macro scale. This is of course dependent on the structural formation of the crystal lattice structure within the material, and the deformation of the crystal on the macro scale. While the piezoelectric effect is responsible for the creation of the transducer device, and several technologies responsible for the production of ultrasound waves, our true understanding needs to be within the inverse piezoelectric effect, or the reverse piezoelectric effect. The reverse piezoelectric effect is the effect responsible for the deformation of an asymmetrical crystal lattice structure under the introduction of an external electrical potential across the surface of the material. This effect is the primary effect behind the basis of this project, and is the foundation on which the methodology of detection of neural activity is built, as under the applied voltage across the crystal from an action potential from a neuron, the crystal will deform, producing a different backscatter wave. The reverse piezoelectric effect is connected closely to the piezoelectric effect, and is the direct result from the asymmetrical charge distribution within the crystal lattice structure of the material. As the inverse of the piezoelectric effect, oscillation of the electrical potential across the material creates an oscillating mechanical deformation within the crystal, creating a wave of sound, and if tuned correctly, ultrasound. This creates an interesting opportunity within the creation of the micro crystals, as the design can both rely on ultrasound backscatter, but also creation of an original ultrasound wave. The effect of piezoelectricity is also important to understand to properly balance the required voltage across a certain size of crystal to create noticeable deformation, with the amount of deformation required for its detection within backscatter, and the equations for which are vast, and incredibly complex. The equations responsible for the prediction of the factors and results of the piezoelectric effect rely on several factors, including the crystal lattice geometry, the voltages, pressures, and overall material properties. Typically, you would first start by describing the constituent properties of the material through the equations that describe the strain, the electric field, and the piezoelectric coefficient, but since this data has previously been discovered and recorded, for the development of piezoelectric requiring technologies, this data, when required for the testing and production of the micro crystal, will be used from these sources. After the basic properties of the material are laid out, we can estimate the strain produced by the piezoelectric effect, but again, this information is already well established, and as such, will simply be used from reputable scientific publications when the time for production and testing occurs. The most important thing to note, the takeaway so to speak, behind the physics of the reverse piezoelectric effect, is that the deformation is miniscule. The unit in which piezoelectricity, and subsequently the inverse piezoelectricity is measured in, is picometers per volt, in the case of a material in the thickness of millimeters. While backscatter can detect this, it becomes an issue when talking about whether it is feasible of a system that is confined to the human body to detect this size of a deformation. This coefficient of piezoelectric deformation of course changes with the size of the crystal, and therefore the amount of energy required to shift the crystal lattice structure of the system, and on the micro scale, the deformation, even in picometers, becomes much more noticeable. And this value further changes because of the size difference, as the energy required to shift the crystal in the same order of picometer deformation becomes less, from a singular volt, so some amount of millivolts, depending on several factors. This understanding of the piezoelectric effect, and the subsequent inverse piezoelectric effect become incredibly beneficial in the design of the crystal structure of the system for several reasons. We can roughly, without conducting any sort of mathematical testing, estimate the crystal deformation of some set crystal under some set voltage, and vice versa, allowing us to create a system that can properly react, or modify, and then react, to the minute signal produced from the action potential of a firing neuron. We can also experiment with different, slightly more hypothetical methods for the detection of activation, such as non-backscatter based systems, that rely entirely on the implanted system to produce an initial ultrasound wave.

1.5.Knowledge Gap and Purpose

The knowledge gap of existing, and already well grounded research, and the necessary questions within this project are very closely interlinked, as there is no reason for asking a question, and conducting experimental analysis within this project to answer it, if it was already something well established, and known. The gap, within the overall scope of the project, that the project aims to fill, is whether a deformation within a piezoelectric crystal can be advantageously used for the detection of neural activity, and if so, what is the most optimal geometry, and set up, as well as creation of the micro sized piezoelectric crystal? The purpose of the project is well outlined, and has several far reaching implications in several fields, the primary of which, and what the project is focused on are medicine, and neurobiology. A system with the appropriate parameters that have previously been outlined, if produced, and if functional, has the potential to expand, and propel our understanding of the functions, functionality, and the overarching complexity within such a large structure as the brain. Not only this, but when applied to less research focused, and research dependent fields, such as commercial and medical use, paralysis, vision, and locked in syndrome all have the potential to be cured. The system, while showing great commercial and medical use potential, if successful, can also be applied to several other sectors of development, such as micro and nano fabrication, ultrasound technologies, and ultrasound and acoustic microscopy.

2.Methods

Now, with a complete understanding of the biological sciences, relating to this project, as well as the properties of piezoelectric materials, we can start to consider the design, development, and testing of the system. This includes, but is not limited to, the production and testing of the micro crystal system, the potential implantation methodologies, the production and testing of the transducer device, and coding of the system for potential medical use. This section outlines aspects of the system such as material considerations, design considerations and designs of the crystal system, as well as the transducer system, the design of the testing set up, and the production of each of these aspects of the project. It also outlines the procedure for testing within the system.

2.2.Research Questions

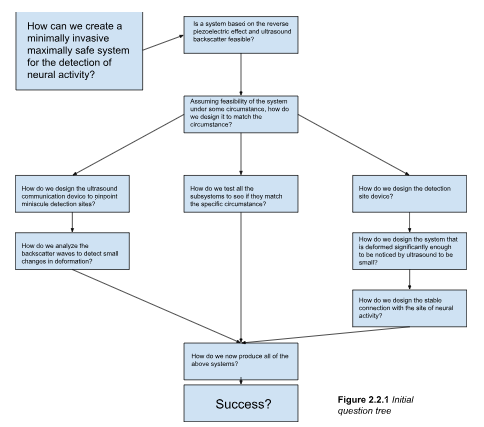

The purpose of this research, and the primary question asked when setting out to conduct this project, was, is it possible to create a minimally invasive system for the detection of neural activity within the human body? When further examined the question itself could be broken up into subsections that analyze and question the safety, reliability, production, and actual detection of activity on a reliable scale. Through not only broad literature review, but also preexisting background knowledge on the topic, the question and primary goal of this research was shifted, from a generalized perspective on the analysis of possibility of such a system, to the creation of a system that relies on the reverse piezoelectric effect, the subsequently created deformation and the resultant patterns of ultrasound backscatter. The question from this point on, narrowed down from the initial purpose of the creation of a minimally invasive and maximally safe device for the detection of neural activity, to the creation and testing of such a system based on the reverse piezoelectric effect and ultrasound backscatter, becomes, is it possible to create a system reliant on these properties, and if so, how? The question, broken down for simplicity and for the quick understanding of the purpose of this research is broken down in figure 2.2.1 below.

The above figure demonstrates a logical progression of questions asked in the development of such a system, and as such is the basis of questions asked, and questions answered in this paper. By splitting the design into first the theoretical, then the developmental stages, the creation of the final product is simplified. It is also important to note that this project is written as both a logical progression of events, especially in the design and production phases, but also as a straightforward recollection and description in the necessary areas, such as the abstract and conclusion sections of the project. Since the project follows a more engineering-like approach to the design of the system, some amount of creative leniency is allowed within the design and description of the design, such as reworks based on foreseen difficulties, or changes to the project that are dependant on results which would have otherwise not been mentioned in that area of the project.

2.3.Initial Design

In the domain of BCI’s, the pursuit of improved spatial resolution, reduced size, and enhanced data collection efficiency prompts the exploration of innovative design approaches. The primary goal is to achieve unprecedented spatial resolution by integrating piezoelectric microscale crystals into the BCI architecture, aiming to surpass limitations related to the bulkiness of conventional BCIs and spatial precision constraints. To reduce the size and intrusiveness of the BCI, the utilization of microscale materials is proposed for seamless integration into neural tissues. This reduction in physical footprint enhances patient comfort and safety, and allows for more precise placement within the neural environment. While the general concept for the use of microscale materials is proposed, the engineering requirements for this system must include, at a minimum, the accurate detection of activation and the precise measurement of the location of activation relative to other implants. The overarching goal is to ensure the system is safe, minimally invasive, and maximizes resolution. The proposal of microscale piezoelectric crystals over other means of detection is one well grounded in previous research.

Free floating implants maximize efficiency of data collection over a broad area of neural tissue, but challenges arise from the transmission of data between the free floating implant and an external decoding device in terms of safety and size of the device itself. Microwires are limited to small areas of neural tissue, and issues such as buckling and displacement arise from the substantially different Young's modulus of the microwire and soft neural tissue. Other instances and methodologies for the detection systems of BCIs can be examined, and all have considerable drawbacks in one or more of several aspects. Microscale implants remain one of the only solutions that balances the issues with current state of the art BCIs, and are feasible. For these reasons, the constraint that the detection device must be at a microscale is placed on the design and development of the device. The goal in creating a device of such a small scale is to allow for maximum safety by effectively bypassing abrasion damage due to differences within Young's modulus of the device and the neural tissue. It is also set out within the goals that the system is capable within an acceptable degree of accuracy to detect and transmit the presence of neural activity. The system must also be maximally safe, and must remain non toxic, as the major driving reason for the development of a microscale BCI is improved safety, in combination with improved spatial resolution, due to the fact that more detection sites can be placed in one area due to their size.

A microscale implant, due to the limitations of current technologies, cannot instantly detect and transmit a signal from its implanted location, potentially several centimeters within tissue, to an external device. Therefore, to enhance the capability of the system while keeping it within the parameters of the microscale, it is important that the actual microscale implant acts as the detection site, and a partner device, most likely located on the outside of the tissue, acts as the receiver of data from the microscale implant. To establish a wireless connection between the two devices, radio waves and other high energy waves, due to the potential for the tissue to absorb excess energy and heat up, are excluded. Ultrasound remains the only feasible method of wireless communication between the detection site and the partner device, without complicating the detection site device, as a microscale piezoelectric crystal can be used. Piezoelectric crystals have been the main methodology for the creation of ultrasound devices, and deform when introduced to an amount of voltage. This deformation is measurable by external ultrasound waves in a process known as backscatter, in which the deformation of the crystal causes a different, and measurable backscatter wave, and is the basis for the entire project. The piezoelectric crystal has the potential to be made small enough to fit within the microscale parameters (20-100 micrometers) of the device while still exhibiting the reverse piezoelectric effect, powered solely by the voltage difference within neural tissue. To minimize size of the detection site device, backscatter can be employed by the partner device to return a different wave depending on the deformation within the micro crystal, which itself is dependent on the voltage imparted on the device. The micro crystal itself must be designed small enough to be safely implanted within neural tissue, and must have a simple enough geometry to be produced via current nanofabrication techniques, while still exhibiting a complex enough geometry that the backscatter is noticeable and distinct. While on the other hand the transducer device must be made small, and effective enough to be placed, primarily, beneath the skull, without negative interaction with the brain matter. Both devices must also be safe enough to be implanted into neural tissues, without causing severe abrasion damage, and without causing long term poisoning from the degradation of the chemical constituents of the devices.

2.4.Material Considerations And Specific Design

With the initial idea described, we can now begin to consider the specific designs of both the implanted microcrystal detection site, and the transducer device, the former of which will be discussed in much more depth than the latter, for the sole purpose of centralizing, and focusing on one area of research within the project, to not only conserve energy, time, and resources. With that being said it is important to understand that the crystal itself, will not be designed and made as a traditional, and simple crystal structure, but is instead, when referencing the crystal, is referencing the complete micro scale detection site, which must be composed out of several different components. All of these components play a vital role within the overall functionality of the crystal system as a whole, and each one must be dealt with carefully. Although there are several subsystems of the crystal structure, it can primarily be broken down into two, the tendrils, or the connective leads between the crystal and the surrounding neurons, to allow for extended range and not just the immediate surface of the piezoelectric crystal, and the piezoelectric crystal itself, responsible for the communication of neural activation, through its own personal deformation, detected by the ultrasound wave produced by the transducer. First, as one of the most crucial aspects of the project, it is important to consider the properties of the piezoelectric crystal itself, as it is responsible for communicating the activation of neurons in its vicinity to the external transducer device. It must be considered for several properties, the primary of which, in the current state of development, is the level of energy required to deform the crystal, and the ease at which the crystal is deformed. It is of course, in the long run important to also consider the toxicity of the chosen material, and the ease at which it can be produced into some chosen geometry, but these will affect our consideration much less than the actual order of deformation of the crystal. The below table is a compilation of all of these factors of some randomly selected materials, all chosen for some part of ease within at least one section of the required fields.

|

Name |

Reactivity and Toxicity |

Order and Strength of Piezoelectric Deformation |

Production Methodologies |

Other Considerations and Overview |

|

Lithium tantalate (LiTaO3) |

Generally safe. Lithium compounds may become toxic if exposure becomes increasingly excess. No adverse reactions can be identified on the biological level if the material is properly encapsulated. If not, complications arise. |

Lithium tantalate exhibits strong piezoelectric properties. For exact value calculations refer to the following mathematical formulas. |

This material, under very specific conditions, can be grown like an ordinary crystal. Under constant agitation from an outside source inside a bath of solution, the crystals can grow, and from there, can manually be chosen for the most optimal conditions. Adjusting flow rate, and agitation amount will also be beneficial to the crystal growth. “Powdering”, is another method for the production of the crystals specifically, which is the process of taking larger crystal pieces and working them down to a smaller size, and hand picking the desired crystals under microscope. While more labour intensive, it may be the only option when techniques involving nanosecond lasers are not available. |

Lithium tantalate is widely used in acoustic optic devices, and other such devices where frequency control due to piezoelectric responses is necessary, due to the materials powerful piezoelectric response. Overall due to the materials general safety, and strong order of piezoelectric deformation, it remains a highly ranked potential candidate for the production of the finished microcrystal. |

|

Lithium niobate (LiNb03) |

Generally safe. Lithium compounds may become toxic if exposure becomes increasingly excess. No adverse reactions can be identified on the biological level if the material is properly encapsulated. If not, complications arise. |

Lithium niobate exhibits strong piezoelectric properties. For exact value calculations refer to the following mathematical formulas. |

This material, under very specific conditions, can be grown like an ordinary crystal. Under constant agitation from an outside source inside a bath of solution, the crystals can grow, and from there, can manually be chosen for the most optimal conditions. Adjusting flow rate, and agitation amount will also be beneficial to the crystal growth. “Powdering”, is another method for the production of the crystals specifically, which is the process of taking larger crystal pieces and working them down to a smaller size, and hand picking the desired crystals under microscope. While more labour intensive, it may be the only option when techniques involving nanosecond lasers are not available. |

Lithium niobate due to the high piezoelectric coefficient is often used in acoustic wave devices, Telecommunications, and modulators. For similar reasons as lithium tantalate, lithium niobate remains a strong competitor for the final production of the micro crystals, due to its general safety and strong piezoelectric effect response. |

|

Langasite (La3Ga3SiO14) |

Generally safe. Compounds may become dangerous in high quantities of exposure without proper encapsulation. |

Langasite exhibits moderate piezoelectric properties. For exact value calculations refer to the following mathematical formulas. |

This material, under very specific conditions, can be grown like an ordinary crystal. Under constant agitation from an outside source inside a bath of solution, the crystals can grow, and from there, can manually be chosen for the most optimal conditions. Adjusting flow rate, and agitation amount will also be beneficial to the crystal growth. “Powdering”, is another method for the production of the crystals specifically, which is the process of taking larger crystal pieces and working them down to a smaller size, and hand picking the desired crystals under microscope. While more labour intensive, it may be the only option when techniques involving nanosecond lasers are not available. |

Due to langecites moderate exhibition of the piezoelectric effect, it is often used for weak surface acoustic wave devices. Overall, while an interesting consideration for the final production of the microcrystal, due to its low piezoelectric coefficient, it will most likely not be selected for initial testing. |

|

Lead titanate (PbTiO3) |

Extremely toxic. Lead compounds are incredibly hazardous, and incredibly dangerous situations may arise from the implantation of lead crystals within neural tissue. Adverse reactions can be avoided on the biological level if the material is properly encapsulated. Otherwise complications arise. |

Lead titanate exhibits strong piezoelectric properties, and any material consisting of lead, primarily, will exhibit incredibly strong piezoelectric properties, with the weak voltage of activation within the material crystal. |

This material, under very specific conditions, can be grown like an ordinary crystal. Under constant agitation from an outside source inside a bath of solution, the crystals can grow, and from there, can manually be chosen for the most optimal conditions. Adjusting flow rate, and agitation amount will also be beneficial to the crystal growth. “Powdering”, is another method for the production of the crystals specifically, which is the process of taking larger crystal pieces and working them down to a smaller size, and hand picking the desired crystals under microscope. While more labour intensive, it may be the only option when techniques involving nanosecond lasers are not available. |

While an unsafe option due to the toxic nature of lead, Lead titanate is an incredibly strong material in terms of the piezoelectric properties within it. And while it is important to mention the safety aspect of the finished product, for our purposes it is incredibly important to consider the strength of the piezoelectric effect within the material, and the activation voltage of the material. It is also important to note that while lead remains an unsafe choice, it is one of the strongest competitors in terms of functionality. |

|

Quartz (SiO4) |

Safe. Quartz crystals are not toxic, and major complications only arise from the inhalation of fine quartz crystal dust. |

Quartz exhibits weak piezoelectric properties, but properties that are nonetheless potentially useful. |

This material, under very specific conditions, can be grown like an ordinary crystal. Under constant agitation from an outside source inside a bath of solution, the crystals can grow, and from there, can manually be chosen for the most optimal conditions. Adjusting flow rate, and agitation amount will also be beneficial to the crystal growth. “Powdering”, is another method for the production of the crystals specifically, which is the process of taking larger crystal pieces and working them down to a smaller size, and hand picking the desired crystals under microscope. While more labour intensive, it may be the only option when techniques involving nanosecond lasers are not available. |

While quartz does demonstrate the piezoelectric effect within its crystal structure; its weak nature may push it out of the running for the finished micro crystal production. This might be changed later on, if safety becomes a higher priority than functionality, due to quarts being non-toxic in nature, and its simplicity within production. |

|

Sodium bismuth titanate (NaBi(TiO3)2) |

Generally safe. Compounds may become affected by biological reactions if not properly encapsulated. |

Sodium bismuth titanate exhibits strong piezoelectric properties, but due to its complexity has a slightly higher voltage of activation. |

This material, under very specific conditions, can be grown like an ordinary crystal. Under constant agitation from an outside source inside a bath of solution, the crystals can grow, and from there, can manually be chosen for the most optimal conditions. Adjusting flow rate, and agitation amount will also be beneficial to the crystal growth. “Powdering”, is another method for the production of the crystals specifically, which is the process of taking larger crystal pieces and working them down to a smaller size, and hand picking the desired crystals under microscope. While more labour intensive, it may be the only option when techniques involving nanosecond lasers are not available. |

Sodium business titanate is used in multi-layer ceramic capacitors, ultrasonic transducers, and piezoelectric sensors. The materials overall strong nature for the piezoelectric effect puts it high in the running for the finished micro crystal production. complexity of the substance may be difficult to work with, but if proven stronger or more effective than other compounds, difficulty within production may be overlooked. |

|

Lead zirconate titanate (PZT) |

Extremely toxic. Lead compounds are incredibly hazardous, and incredibly dangerous situations may arise from the implantation of lead crystals within neural tissue. Adverse reactions can be avoided on the biological level if the material is properly encapsulated. Otherwise complications arise. |

Lead zirconate titanate exhibits the strongest piezoelectric properties out of all the materials on this table. As it is a lead containing compound, its voltage of activation also remains relatively low, and the strength of the piezoelectric deformation remains high. note that for all of the aforementioned chemical substances exact calculations can be done using the mathematical formulas given in the following pages. |

This material, under very specific conditions, can be grown like an ordinary crystal. Under constant agitation from an outside source inside a bath of solution, the crystals can grow, and from there, can manually be chosen for the most optimal conditions. Adjusting flow rate, and agitation amount will also be beneficial to the crystal growth. “Powdering”, is another method for the production of the crystals specifically, which is the process of taking larger crystal pieces and working them down to a smaller size, and hand picking the desired crystals under microscope. While more labour intensive, it may be the only option when techniques involving nanosecond lasers are not available. |

Lead zirconate titanate is one of the most widely used piezoelectric materials today, its strong nature for the piezoelectric effect puts it incredibly high, or rather first place in the running for the finished product of the micro crystal, in terms of functionality. Due to the compound's lead makeup, this might change if priority is shifted from functionality to safety. |

|

Sodium tungstate (Na2WO3) |

Generally safe. Adverse reactions within biological matter do not require a special encapsulation, unlike many other compounds. |

Sodium tungstate exhibits weak piezoelectric properties, with a high voltage of activation. |

This material, under very specific conditions, can be grown like an ordinary crystal. Under constant agitation from an outside source inside a bath of solution, the crystals can grow, and from there, can manually be chosen for the most optimal conditions. Adjusting flow rate, and agitation amount will also be beneficial to the crystal growth. “Powdering”, is another method for the production of the crystals specifically, which is the process of taking larger crystal pieces and working them down to a smaller size, and hand picking the desired crystals under microscope. While more labour intensive, it may be the only option when techniques involving nanosecond lasers are not available. |

Sodium tungstate, due to its weak nature for the piezoelectric effect, may be completely excluded from the running for the final finished product of the microcrystal, unless ease of production within this material overrules the functionality of other materials. |

|

Potassium niobate (KNbO3) |

Generally safe. Adverse reactions within biological matter can be avoided within proper encapsulation of the crystal material. |

Potassium niobate exhibits strong piezoelectric properties. |

This material, under very specific conditions, can be grown like an ordinary crystal. Under constant agitation from an outside source inside a bath of solution, the crystals can grow, and from there, can manually be chosen for the most optimal conditions. Adjusting flow rate, and agitation amount will also be beneficial to the crystal growth. “Powdering”, is another method for the production of the crystals specifically, which is the process of taking larger crystal pieces and working them down to a smaller size, and hand picking the desired crystals under microscope. While more labour intensive, it may be the only option when techniques involving nanosecond lasers are not available. |

Potassium niobate used in piezoelectric devices and optical acoustic applications. Not much else can be said about the material besides the fact that if ease of production is incredibly evident within the material, it may be used within the creation of the final product of the micro crystal system. |

As is outlined by the above table, the materials all exhibit some form of positive inclination towards one beneficial trait. It is also important to note, that generally, compounds with a lower LD50, and more toxic and reactive compounds tend to have a higher order of crystal deformation due to the piezoelectric effect. This remains a complication when balancing the order of piezoelectric deformation with the safety of the crystal, but this might be a somewhat irrelevant aspect within the overall design, as the crystal can always be covered with a biologically safe compound. This of course has the potential to lead to further complications within degradation of the crystal, but let us overlook and ignore, for the favour of the testing of functionality and plausibility, before working on a finished product, ready for medical testing.

Besides the considerations of material for the piezoelectric crystal itself, it is also important to consider the material out of which the connective leads, or the tendrils for the systems will be made out of. This becomes a much simpler process, because it is logical that the material with the highest conductive value possible is selected. For situations in which resistive values are desirable within the system, another, semi conductive, or conductive material with lower electron permeability than the primary tendril will be chosen. The highest conductive raw metal is silver, and because systems for the growth of silver exist within chemistry, the process of growing connective tendril-like structures on the piezoelectric crystal will also remain simple. For situations in which a higher resistive value is necessitated, copper, or gold may be used, since techniques for the growth of these crystals also exist, and they have a considerably lower electron permeability than silver.

2.4.1.Crystal Design

If a micro scale crystal implant is made out of a material that exhibits the piezoelectric effect, then small patches of conductive material are placed on the crystal acting as the ground and extending connections, then a voltage difference from the firing of a neuron would force the crystal to undergo deformation. If a partner device was then to send out a “seeking” ultrasound wave, the backscatter wave that gets returned from the newly deformed micro crystal will be different from that of the non deformed baseline crystal backscatter. Backscatter waves under this central idea of deformation causing a different wave are also highly practical, as neural tissue does not contain areas which may act similarly to the implanted micro crystal, cutting down on background detection noise. It is also possible within this system to exploit the fact that the deformation of the crystal is proportional to the electric field applied, and therefore, if several leads of microwires are created with variable resistances then the deformation within the crystal would be proportional to the voltage. If the difference in the backscatter wave is evident enough, it would be possible to associate each wave pattern to a certain microwire, and therefore, a different position relative to the implant. The simplest method for the creation of the main piezoelectric crystal within this system would be to create a cube-like structure, but this may not result in the most sought after effect, and therefore, several different iterations of the crystal must be created besides the cube-like structure.

The cube, while the simplest in principle structure to create that will be beneficial to us, is still not as simple as shaping a crystal into a cube. Since the micro scale requirement of the crystal, or rather the entire system itself, so the actual piezoelectric crystal becomes smaller than expected to fit within the size constraints, simple procedures for the shaping of the crystal will be insufficient. Even proper procedure for the production of the crystal will become insufficient, due to monetary and time constraints. For this, a simpler methodology must be examined than additive manufacturing in a super controlled environment, or super controlled subtractive manufacturing methods, to properly shape the piezoelectric crystal of the micro system itself. Instead of these methodologies, it is proposed that we take advantage of the fact that the system itself, as well as the piezoelectric crystal can be grown like an ordinary crystal. We introduce the crystal to a bath solution, and entice a crystal growth on the surface of some outside particle, acting as a stable grounding point for the crystal, to allow the disposition of the piezoelectric material on the surface of the outside material particle. This simplifies the process of the creation of the crystal itself for several different reasons, as we can use outside particles produced by super effective means into certain shapes of designated size, like a disk, a cylinder, or a cube, to properly produce the desired piezoelectric crystal into the desired structure. The fact that there may also exist the material within the finished piezoelectric crystal, may in the long run benefit us in the detection of the backscatter, as both materials will have different acoustic impedances, creating several backscatter waves, but this is just a theory, and will need to be experimentally tested later. So with this, it just becomes a challenge to predict the most desirable shape of the crystal itself, and then produce the system around that shape of crystal. As previously described, a cube will be a simple start, but to add to that, another simple geometry that we may want to consider is a sphere. While more difficult to account for, in terms of piezoelectric deformation, both the order, and the effect of deformation, it might surprise us if tested experimentally. Besides this, it may also benefit us to use some sort of more complex structure for the crystal itself. Besides the spherical, and cube-like structure of the previously proposed shapes of microcrystals, we will also design and produce systems that include a cylindrical crystal, a flat disc crystal, and a randomly grown crystal shape, similar to that most like a snowflake. A table of all of the ideas for the grown shapes can be seen below, as well as the rationale for the design of the particular shape, as well as the predicted size.

|

|

Rationale: The cube-like structure provides simple anchoring points for the tendrils, or the connective points that allow for the extended detection of neural activity around the crystal. It also allows for the most effective deformation prediction of all of the other shapes, as the piezoelectric coefficient can easily be used in such a simple shape. |

Size Prediction and Attachment: The size of this shape will be slightly larger than average, at possibly more than 100 micrometers. The attachment points for the crystal will be on opposite ends of the crystal itself, and the wires will connect directly to the crystal, without the need for an external system. |

|

|

Rationale: The spherical structure, while providing little simplicity within the production of the tendrils, and within the estimation or prediction of backscatter, is a simple shape which provides us with the possibility of producing a vast number of them for testing purposes. |

Size Prediction and Attachment: The size of this shape can be varied from the smallest, to the largest, due to the simplicity of growing crystal spheres. Attachment points for the tendrils will be all over the crystal, producing a “fuzzball” like shape of branching tendrils. It will not require the use of an outside system. |

|

|

Rationale: The cylinder, similarly to the cube, allows for some incredibly simple mounting points for the connective tendrils. Its deformation is also rather simple to predict, and so is a great overall contender for the final shape of the piezoelectric crystal. |

Size Prediction and Attachment: The size of this shape will have to be similar to that of the cube, as the connection points for this shape or on the circular ends of the cylinder. The tendrils will attach to the shape directly, and will not require an outside system. |

|

|

Rationale: The flat disc, while at first appearing as a simple contender, is rather complicated. It is imagined that within the design of the crystal system, the cylinder acts as a collection and reverberation plate, which will produce substantially different ultrasound wave backscatter, when deformed. |

Size Prediction and Attachment: This shape will have a moderate size, as the wires will connect to either end of the circular disk. This system will also require an external system, producing a larger shape than usual, but a better predicted ultrasound backscatter, in terms of the distinct nature. |

|

|

Rationale: The random crystal growth is also an incredibly simple method for the production of the piezoelectric crystal itself. It remains the simplest to grow, and the simplest to attach tendrils to. |

Size Prediction and Attachment: This shape can also vary in size, as the crystal can just stop being grown once the desired shape and size is reached. The tendrils, similarly to the spherical fuzzball, will be grown randomly on the crystal surface. |

As displayed by the table of the image and the rationale for the creation of the specific crystal shape, all of the above will be produced for several different reasons. It is also important to note, that only one of the shapes requires an external surrounding system of a material that is not directly the tendril connective leeds, or the piezoelectric crystal, that being the disc. This is not due to any reasoning, besides the fact that it seems like an interesting idea to consider it almost as a speaker set up. If the crystal is suspended within the larger system, then is deformed, the backscatter from the freely vibrating crystal, suspended by metallic connective wires, would produce an interesting backscatter. It is also important to note that no definite size for the crystals is given within the design parameters, that is for the sole purpose of simplicity within production. Creating a set restriction on the size of the crystals within this stage will be beneficial, but it will be only that, a restriction that the crystals cannot go over. For the purposes of simplicity, a maximum size of 200 micrometers is set as the maximum of the crystals. That places it within the size small enough to not damage the tissue significantly, while still making it large enough to have a distinct shape.

2.4.2.Tendril Design

The micro tendrils are the connective leads that branch from the piezoelectric crystal, and act as its connection with the surrounding neural tissue. Each tendril, as mentioned previously will be designed with a different resistive property, after the successful production of the initial, non variable resistive tendrils has been verified as a functional method of production, allowing for a more accurate detection of activity around the implanted crystal, and therefore a higher spatial resolution. Each tendril must also be designed with a covering, exposing only the very tip of the tendril, as to avoid confusion within detection, as the tendrils will be positioned in the most optimally spread apart places, the detection must occur on the very edge of the area of influence of the device. The microtendril will be made out of several material iterations, and later attached to the piezoelectric micro crystal for simplicity of testing within the tendril system, or rather grown on the microcrystal system, dependant on whether the tendrils are attached to the crystal itself, or the system around it, and each iteration will be made out of a different combination of materials. Gold, silver, and biocompatible polymer will act as the central core of the tendril, and the polymer will be sandwiched between the other conductive material to act as the resistive layer within the system. This sandwiching technique will be continued by altering a layer of resistive polymer and gold or silver. Since each layer of the resistive material has a set thickness, and the resistance of the material is known, it would be possible to determine the total resistance, and alter the deformation of the crystal because of it. It is also important to note, that in this section, the discussion of the production of the surrounding containing system, as previously mentioned, will occur.

The design of the tendrils is simple for smaller crystal structures, such as the sphere, and other crystal structure on which the tendrils can randomly be grown under conditions of constant fluctuation, and no other maintenance of the system of growth is required, but placing the crystals in the tendril bath, and waiting for adequate growth. For other systems, where proper placement of the tendrils on specific locations of the crystal, this process becomes much more difficult than just placing the crystal within the bath and watching the growth of the tendrils. But this can be made easier if the crystals that require precise placement are larger than the crystals which don't, which in this case is true. The crystals which require specific placement of tendrils are larger, and therefore, need larger tendrils, which also means that the crystals can not only be handpicked, but so can the tendrils be hand placed individually on to the crystals. This is exactly what will be done within these systems, and this will also allow for the production of variably resistant tendrils, allowing for equally variable crystal deformation, meaning higher spatial resolution within the system. The problem now becomes the production of the surrounding system around the microcrystal. This is especially important within the case of the flat disc, which requires a circular, dream catcher-like surrounding system for the adequate suspension of the crystal disc. This is an unavoidable difficulty that must be faced head on, and some amount of extended expenditure will be allowed, solely for this purpose. If it is still not possible to create such a system, even with extended expenditure, out of preferably silicon wafers, then the flat disc will be resorted to a simple system that does not contain a surrounding containment system, and will just act as an independent crystal.

2.5.Previous Methods

This section will analyze both the previous methods of production of crystals on such a small scale, but also the tendrils, and when necessary, the surrounding system encapsulation. This will become the background basis for the personal production of the effective system of production later on. In essence, the methods in each system of production are simple, and could theoretically be done with relative ease. Initially, without the use of complicated methods of synthesising the desired crystals, it should be possible to simply include a point of nucleation for the crystals of the desired shape, and slightly smaller of the actual desired size. If this nucleation point is made out of a non reactive, preferably porous material, and produced externally, then the production of the crystals can be done simply, as the constituent chemicals can be mixed under the preferred conditions, and then forced to undergo nucleation of the crystals on to the desired nucleation points. Constant irritation and mixing of the solution tank will be necessary to ensure that multiple nucleation points do not form one large crystal, but otherwise, the process would remain simple, and effective. This can also be done similarly with the tendrils. While the conditions would have to be modified to allow first a deposition of a thin film of the tendril material onto the crystal, and then modified again to allow secondly, the growth of said tendrils of material on the initial surface coat of the crystal. Note that the entirety of the crystal cannot be coated in the metallic material, as then, there would be little piezoelectric effect occurrence, while not zero, it would be so little that it may potentially harm the results. Because of this, care must be taken to ensure that the entirety of the crystal is not covered, and that the crystal remains at least partially exposed, or rather, the coating doesn't connect on all edges. Other methods will also of course be analyzed, to create a more well rounded procedure for the manufacture of the system.

Template Assisted Synthesis:

Template assisted synthesis is similar to the technique already discussed within this section. By employing the use of a “template” for the crystals to grow within, or around, this technique can produce the desired micro crystal shapes. Many such templates exist, such as those which the crystals can grow within, restricting further growth of the crystals while the template exists, and being removed once the template is no longer needed for the growth of the crystal. This technique is viable for the growth of the majority of the crystal structures, as it will simply be removed once no longer needed. This technique will work well, but if not carefully planned, may result in disastrous results within the proper formation of the crystal. Below is an example of the types of structures that are common within this methodology.

This technique involves the creation of a solution of the precursor chemicals, and then producing crystal structures within, or around the template. This is done by ordinary means, by adding a second agent to kick the crystals into the nucleation process, or to produce the crystals. Furthermore, the technique involves the destruction or removal of the surrounding template via chemical means, leaving only the desired grown crystal, which can further be changed by altering the amount of irritation the crystal experiences during growth, and the temperature at which it is grown.

Sea Urchin Growth Technique:

The sea urchin growth technique is a technique for primarily the growth of the conductive tendrils surrounding the piezoelectric crystal itself, and is a rather simple process for the production of conductive tendrils on the surface of the crystal without first requiring the deposition of a film on top of the crystal. The process is rather simple, and involves introducing previously made particles of the material to the later growth stages of the crystal growth process, and then building up the little particles into long extensive tendrils. This process requires two primary things, the premade particles of the material desired to be grown, and a solution of the material that will be grown. By changing the factors of the solution while the crystal, with several particles of the desired growth material placed on the surface of the crystal, we can entice the growth of the tendrils onto the particles. It must also be noted that this method is reserved for the simpler, smaller particles where the variably resistant tendrils are not required. It also must be noted that this method is primarily for the production of nanoparticles, but with the appropriate changes can be introduced here. An example of the growth process can be seen in the below diagram.

While the above example uses gold, and silica nanoparticles, this can be repurposed for our uses, by swapping out the rough silica nanoparticles for rough particles of the piezoelectric crystal. But overall, this method will produce most of our simpler crystal designs that require tendrils.

Simplified Solution Crystallization:

Simplified solution crystallization is the randomized crystallization of both the piezoelectric crystal, and the tendrils that surround it. This method, while simple, is the one that will produce the least satisfactory results, and will most likely only be used on the randomized crystal structure design of the piezoelectric crystal. This will produce completely randomized piezoelectric crystals, as well as tendrils, and will be done by creating small nano nucleation points within a solution of the primary composed chemical within the piezoelectric crystals to allow for proper growth of the crystal within the solution. This will also be identical within the growth of the tendrils on the grown crystal, and the process needs little further explanation. By varying the temperature, pressure, and the irritation of the solution bath, it may be possible to some extent control the production and growth of the crystal, but this is not beneficial to us, in almost any way. This shape design of randomized growth within the piezoelectric crystal is designed almost entirely as a control for the other crystal shapes, because the randomized crystals may have the ability to form into somewhat desirable shapes. Overall, this method is a sort of last ditch methodology for the creation of the crystals if either time, or money becomes low.

2.6.Production

With the understanding of the required principles, and the rough design of the crystals complete, the production phase can begin. It is also important to note that the design stages of the project were rough, outlined ideas for the actual production, and in this stage of the project, the actual production of the roughly outlined designs could commence, to create better, more effective systems. It is also important to note that because of the nature of the project being somewhat reliant on the engineering principles, and the methodologies of engineering and the engineering cycle, being too reliant on a preconceived plan of some preconceived method of function will be detrimental to us. Instead, we go off of a rough idea, and produce a polished product based on our understanding of the methodologies, and the principles within the concept, and as such, things are prone to change. Nevertheless, let us continue with the production of the microcrystal system within this section, which will primarily outline four things, that being the procedures within the production of the finished systems, of the polished system from the rough idea design stages, as well as extra systems from foreseen issues and complications, the reasoning for which will be outlined here, the potential changes made within the procedure, and the finalized outlining of all of the above details. With this, let us analyze the production methodology used for the creation of the majority of the crystals, and their representative surrounding detective systems, such as the case of the DreamCATCHER system, with the production of the flat disc piezo crystal, and the fuzzball system in the case of the spherical piezo crystal. For the sake of simplicity, only two materials were chosen to produce the piezoelectric crystals, as production of more than two types of crystals, in terms of material, and the testing of these subsequent systems would be far too consuming in terms of resources and time. The two materials chosen were lead zirconate titanate and quartz, the former for its excellent piezoelectric coefficient, and the latter for its simplicity and relatively low reactivity and non toxic nature. Quartz, due to difficulty within its growth, was not produced using artificial controlled production. Instead, in the case of quartz crystal, it was powdered and milled into the desired shape, or rather powder into spherical pellets, onto which the tendrils could then be grown using artificial controlled production. The overall procedure for the production of the crystal quartz is simple, and will be looked over first.