Electroplating

Grade 6

Presentation

Hypothesis

Nickle will prevent rust, and will be easiest to plate. The electroplating will work.

Research

1. Electroplating is the process of coating one metal onto another through the use of an electric current.(google search)

2. Electroplating is used for many reasons, sometimes to improve the durability of a metal, or sometimes to make the metal to look better. There are many benefits.(google search, https://www.sharrettsplating.com/blog/engineers-know-electroplating/)

3. We learned how to electroplate(https://www.youtube.com/watch?v=G-PtnwtOR24)

4. Nickel plates easiest.(My friend/science fair partner said it. We proved it when experimenting)

Variables

Voltage, solution conductivity, wait time, type of metal, distance apart of anodes.

Procedure

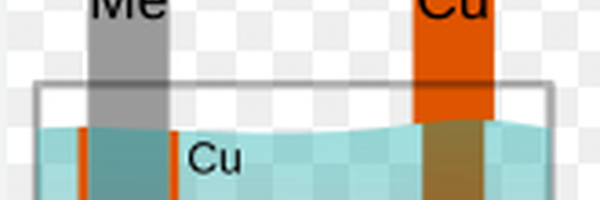

- Put vinegar in container

- Add pinch of salt

- Stir evenly

- Clean part/ take of all rust

- Bend plates and hang opposites sides in solution

- Connect wires to plates. 1 wire/plate

- Let it sit for 25-40 minutes(charging)

- Replace the plate with bubbles on it with what you want to electroplate

- Let is sit for another 25-40 minutes (electroplating)

- Take out electroplated item

Observations

Nickel plating is easiest, Copper plated things rust easily, copper sulfate plating requires less voltage and time, bubbles come from the negatively charged piece of metal, there's anode mud on the bottom of the copper sulfate plating container, but not nickle. Anode mud is impurities.Nickle and copper plating uses 4-5 volts and has a wait time of 25-40 min, while copper sulfate use 1 volt and 5-10 min.

Analysis

Conclusion

In conclusion, electroplating was very successful. It also has many benefits.Nickel and Copper Sulfate didn't rust, and Nickle and Copper use higher voltage and more time to plate. Copper easily rusted. Copper Sulfate took less time and lower voltage to plate. Nickel was the easiest to plate and was the most succesful. Copper was the hardest to plate.

Application

Electroplating can be used to make metal more durable, anti-corrosive, smoother, have better conductiveness, and much more. This could be used on metal things that experience a lot of wear to make them last longer, like railroad tracks and bridges, or on utensils to make them look better.

Sources Of Error

wrong wait time, wrong voltage, to much salt, wrong type of metal used, wrong procedure

Citations

to search some things up, as well as watching how to electroplate on youtube(https://www.youtube.com/watch?v=G-PtnwtOR24

). I also used the infomation from this web(

https://www.sharrettsplating.com/blog/engineers-know-electroplating/).