Is Mycelium The Key to a More Sustainable 21st Century Lifestyle?

Justin Tan

Grade 9

Presentation

Problem

Problem

In this project, I investigated how mycelium can be an alternative 21st century building material. The focus is on repurposing the byproduct of mushroom cultivation, known as mycelium, to address various real-world applications that are significant contributors of global emissions. Mycelium has numerous attributes, such as being lightweight, moldable, or easily compostable enabling it to be a sustainable and environmentally friendly alternative to materials that are currently used widely.

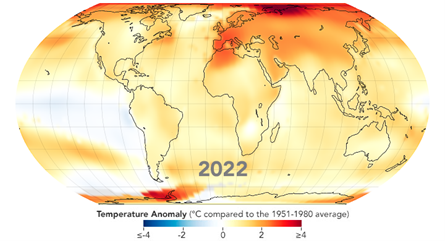

Over the past few years, there have been many indications that Global Warming and Climate Change are becoming more concerning. Since 1880, the average global temperature on Earth has increased by at least 1.1°C (NASA, 2022). However, Global Warming does not mean temperatures rise everywhere at the same rate. Temperatures may rise five degrees in one region but drop two degrees in another.

Figure 1: Global temperature anomalies in 2022 (NASA, 2022).

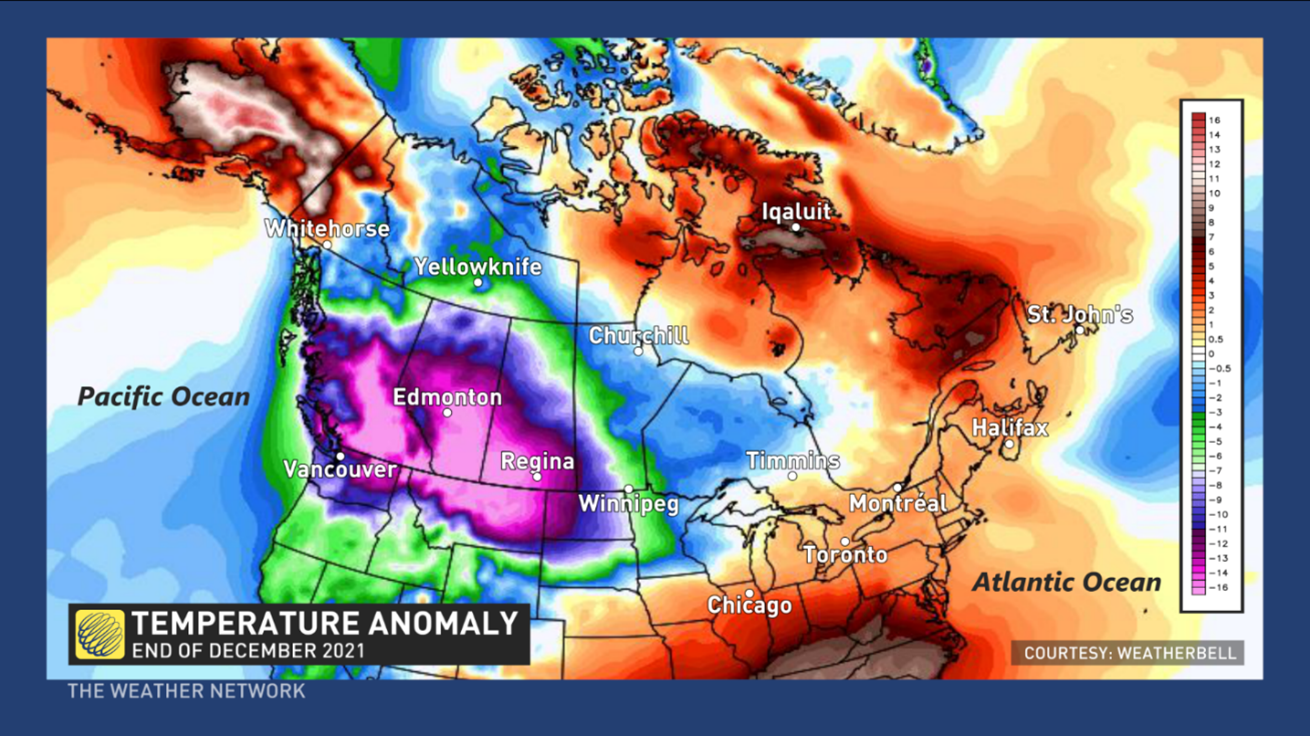

For instance, on December 26, a temperature of -51.1°C was recorded in Rabbit Kettle, Northwest Territories, but the Alaska town of Kodiak, only fifteen-hundred kilometers away, reached a temperature of 19.4°C, almost a 70°C difference. (Corp, 2021).

Figure 2: Temperature anomaly between two with a 70°C temperature gap (Corp, 2021).

Hypothesis

Based on my preliminary research, I am optimistic that mycelium can become an alternative environmentally sustainable 21st century material.

Method

Methodology

Hy-Fi, a zero carbon emissions compostable structure, was a twelve-meter, building made of ten thousand bricks grown naturally from mycelium and corn stalks (Benjamin, n.d.). According to the article, after three months of hosting cultural events, it was disassembled, and composted.

Figure 3: Hy-Fi building in real life (Benjamin n.d.).

This piqued my curiosity and I wanted to find more about this amazing material.

I started my research in September 2023 and have recorded all my findings into my scientific logbook.

When researching this project, I gathered information from many different sources. This included government and corporate websites, news articles, scientific reports, and YouTube videos. Some of the more notable sources were the United Nations Environment Programme (UNEP), National Aeronautics and Space Administration (NASA), National Library of Medicine (NLH), and Forbes.

Besides researching online, I also approached Dr. Tatenda Mambo, a postdoctoral scholar at the University of Calgary’s Sustainability Studies, who manages the experimental Simon Farm. Dr. Mambo is an expert in mushroom growing, having researched into using spent coffee grinds to grow mushrooms. Not only did he provide invaluable guidance during my research, but he also provided me with different strains of mushroom culture to carry out my experiments.

For me to understand the perspectives of my audience, I shared all my project findings with my teacher, friends, and family. Their feedback and insights were then incorporated into my final write up.

Background Research: What is Mycelium?

When mycelium comes to mind, you may think of the green or blue mass growing on moldy food such as cheese or bread (Johnston & Brewer, 2023). However, mycelium are the parts of a fungus other than the mushroom. It is most commonly hidden from sight growing in the soil or under rotting logs creating huge networks of tiny fungal strands called hyphae.

Figure 4: Mycelium colonizing the soil creating huge networks of hyphae (Caucus Blog, n.d.).

The hyphae travel through the soil and other substrates where fungus is found, secreting digestive enzymes onto the dead organic materials and occasionally living things that serve as their food source.

These enzymes decompose the material into smaller pieces that nourish several other creatures in addition to the fungi and their plant partners. In reality, the breakdown of organic matter is essential to the health of the soil, the recycling of leaf litter, and the delivery of food for the multitude of microorganisms and creatures that live in the soil (Johnston & Brewer, 2023).

Figure 5: Mycelium colonizing the soil under mushrooms (Souza, 2020).

Mycelial networks come in different sizes. While the majority are microscopic, some have the ability to grow to enormous sizes. Would you be surprised that the largest organism in the world is actually a mycelial network? Named the “Humongous Fungus”, it occupies approximately one thousand hectares of soil and is located in the Blue Mountains of Oregon (Casselman, 2007). That is the size of more than sixteen-hundred football fields or three blue whales (Daley, 2018).

Figure 6: Closeup shot of the fruiting body of the “Humongous Fungus” (Daley, 2018).

Experiment: Creating Mycelium-Based Bricks

The process of constructing commercial concrete bricks is very carbon-emission intensive. This was my inspiration to create bricks out of mycelium just like how Ecovative used mycelium bricks to build Hy-Fi. My goal was to test if mycelium-based bricks would be able to replace commercial concrete bricks.

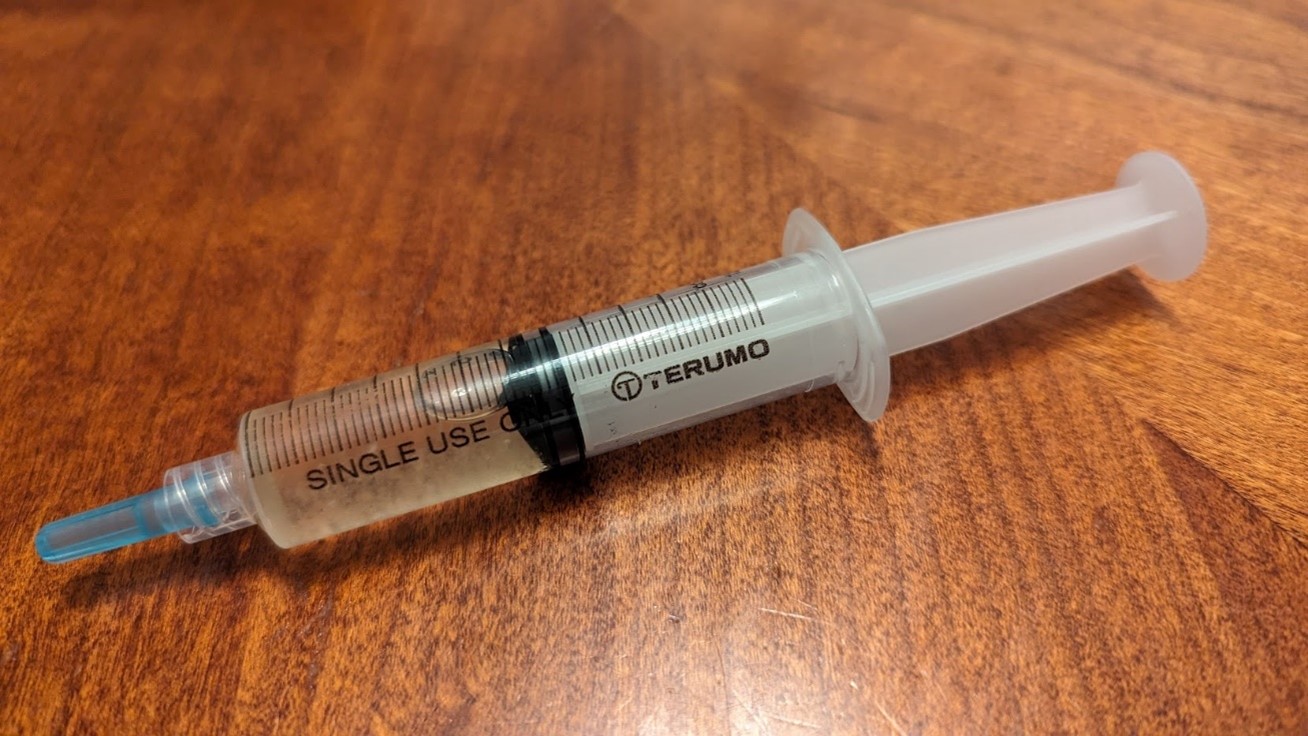

Mushroom liquid culture is a popular method of propagating mycelium. The culture is a mixture of mushroom spore and mushroom, suspended in a liquid growth medium. The mushroom spore is the source of all the genetic information needed to grow mushrooms, and the liquid culture provides a convenient way to transfer this information to the growth medium.

Figure 7: Image of liquid culture in a syringe (Own Photo).

There are different types of liquid culture, including pure culture and mixed culture. Pure culture is made from a single strain of mushroom, while mixed culture is a combination of several strains of mushrooms. For my experiments, I used liquid culture for both the Blue Oyster and Turkey Tail mushroom strains.

The liquid culture was used to inoculate a substrate, such as a mixture of grain or sawdust, which acted as a food source for the mushrooms. I injected these "liquid mushrooms" into an inoculation jar of whole oats.

There were a couple of steps needed to prepare the jar of grains. First, I had to hydrate the grain by boiling it at low heat for an hour, and then letting it sit in the liquid for approximately twenty-four hours. Then, I transferred these grains into a mason jar, sealed the jar, and sterilized it using a pressure cooker for about two hours to eliminate any mold or contamination. After the sterilization, the jar of oats was left to cool down in the pressure cooker for about twelve hours. This was necessary because the heat could kill the mushroom spores in the liquid culture. Once the sterilized jar of oats had cooled down sufficiently, I added the liquid culture through an injection port and kept the jar in a dark environment for two weeks.

Figure 8: Closeup shots of the inoculation process (Own Photo).

When the oats had been fully myceliated, I started preparing the fruiting bag. The fruiting bags contain nutrient rich materials such as hard wood pellets. These hard wood pellets are first hydrated using boiling water. I kept the weight of the water and the weight of the hard wood pellets equal. This was left in a sterilized cooler box for about twelve hours. Once it had cooled, the colonized grain from the inoculation jars were added to the fruiting bag and the bag was sealed.

The grain from the inoculation jar acted as numerous “inoculation points” for the mycelium to start growing. As the hyphae of the mycelium branched out in its search for food, it would create a network in the substrate. Observing the hyphae colonize the substrate was quite fascinating. Since there were so many grains from the jar, the process of creating mycelial network took a little less than two weeks.

Figure 9: Different stages of the mushroom fruiting process (Own Photo).

Once the fruiting bags were fully myceliated, I cut slits in the bags and placed them in a high humidity tent. As the days went on, mushrooms started to appear from all sides. Some mushroom strains like Blue Oyster were more aggressive so the mushrooms (“fruits”) grew quickly. After just thirteen days, I harvested those mushrooms and created a stir fry dish with them. They had a very smoky flavor, and their texture was quite chewy.

After harvesting the mushroom, I then broke up the remaining myceliated substrate in the fruiting bag. Upon sifting out the oats, I packed the substrate into a brick mold. After a week, I took the mycelium bricks out of their molds and placed them into an oven, baking it for a few hours. The heat helped to remove the moisture from the bricks and killed the mycelium. At this point, they were finally ready to be experimented with.

Figure 10: Images of the final steps of creating the bricks. On the left, I am packing the substrate into their brick molds and the other two photos showcase the baking process (Own Photo).

Experiment: Mechanical Tests

There are a series of tests for commercial bricks related to their compressive strength, hardness, water absorption, thermal conductivity, soundness, and their overall strength. Due to a lack of appropriate facilities and equipment, I only tested the mycelium bricks for their tensile strength (weight bearing capability), water and fire resistance.

Mechanical Test 1: Tensile Strength (Weight Bearing Capability)

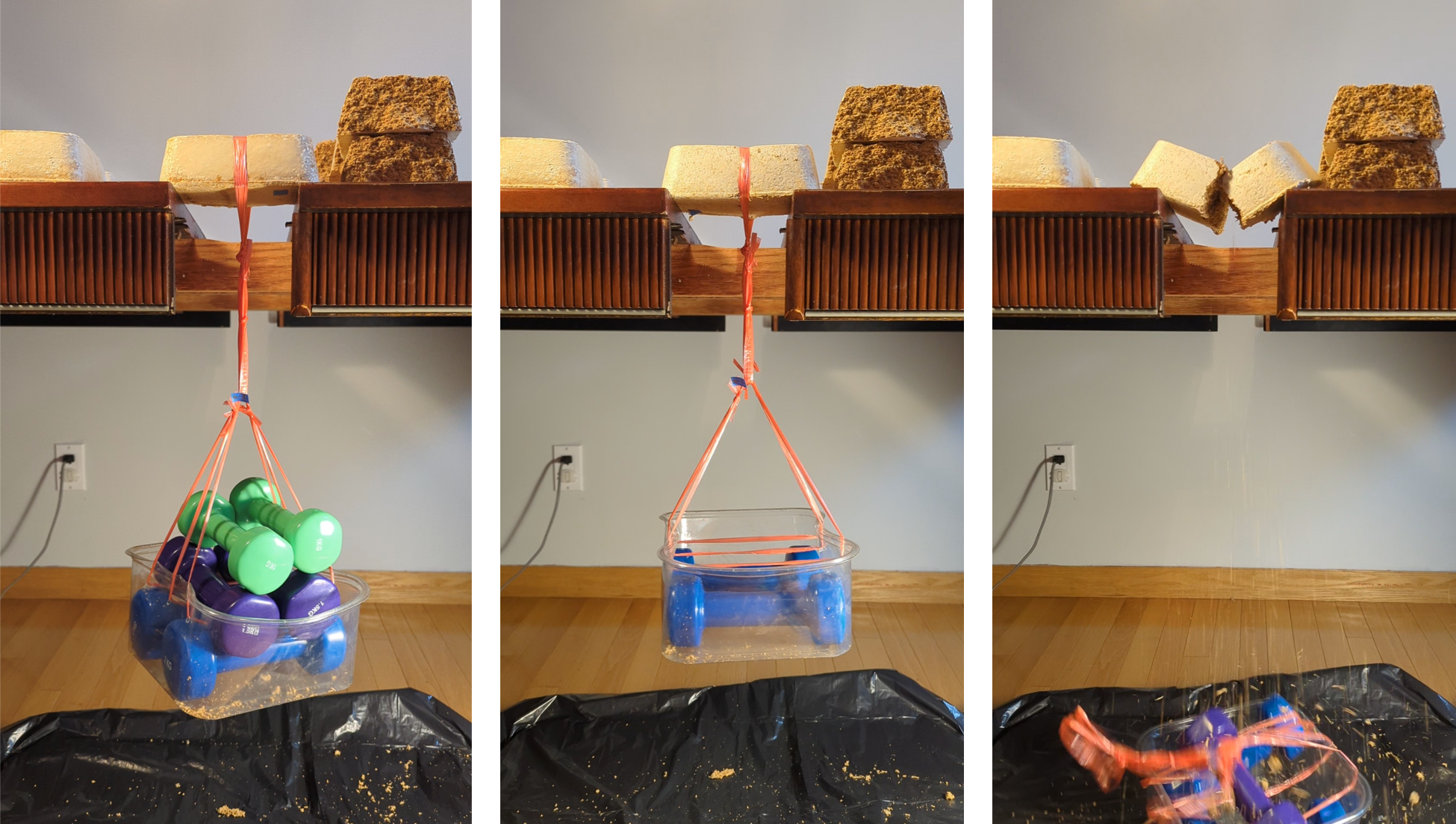

Below are some images of the strength test that I performed. I attached a bucket of weights with a string to the brick. I slowly added weights to the bucket until the brick eventually snapped.

Figure 11: On the left photo, is a Turkey Tail brick successfully holding nine kilograms of weight. The two photos to the right are the moments before and after disaster for the Blue Oyster brick (Own Photo).

Mechanical Test 2: Water Resistance

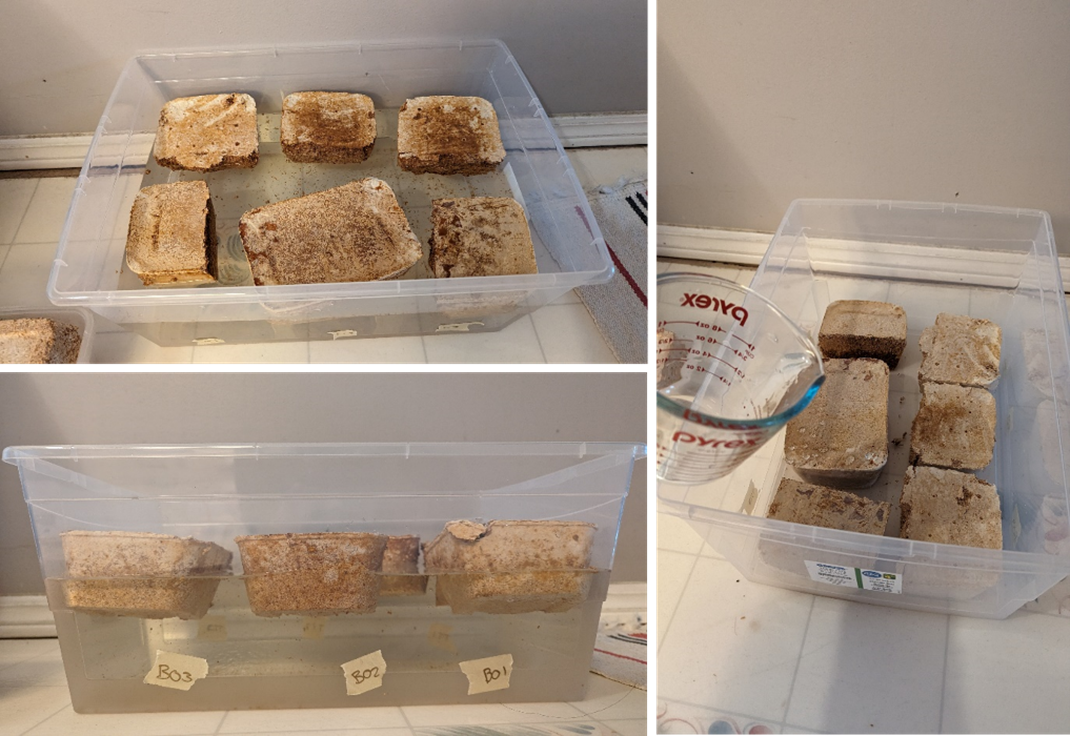

To test their water resistance, I soaked the bricks in water for over twelve hours. To measure the amount of water they absorbed, I weighed the bricks before and after being immersed.

Figure 12: Process of submerging the bricks in water (Own Photo).

Mechanical Test 3: Fire Resistance

My fire resistance test consisted of blowtorching the mycelium bricks for 20 seconds, observing if they would catch fire.

Figure 13: Process of blowtorching the bricks (Own Photo).

Analysis

Results

Mechanical Test 1: Tensile Strength (Weight Bearing Capability)

Tensile strength calculated with the formula:

s = F/A

s = tensile strength

F = force

A = area

Unfortunately, my tests were fundamentally flawed. In my test, I wrapped a string around the width of the brick, resulting in most of the force being applied to the corners. Instead, I should have placed a metal beam on the top of the brick and tied weights to the ends of the beam. If the beam remained rigid, the weight would be uniformly distributed throughout the brick's top surface. As a result, I did not calculate the tensile strength of my mycelium bricks.

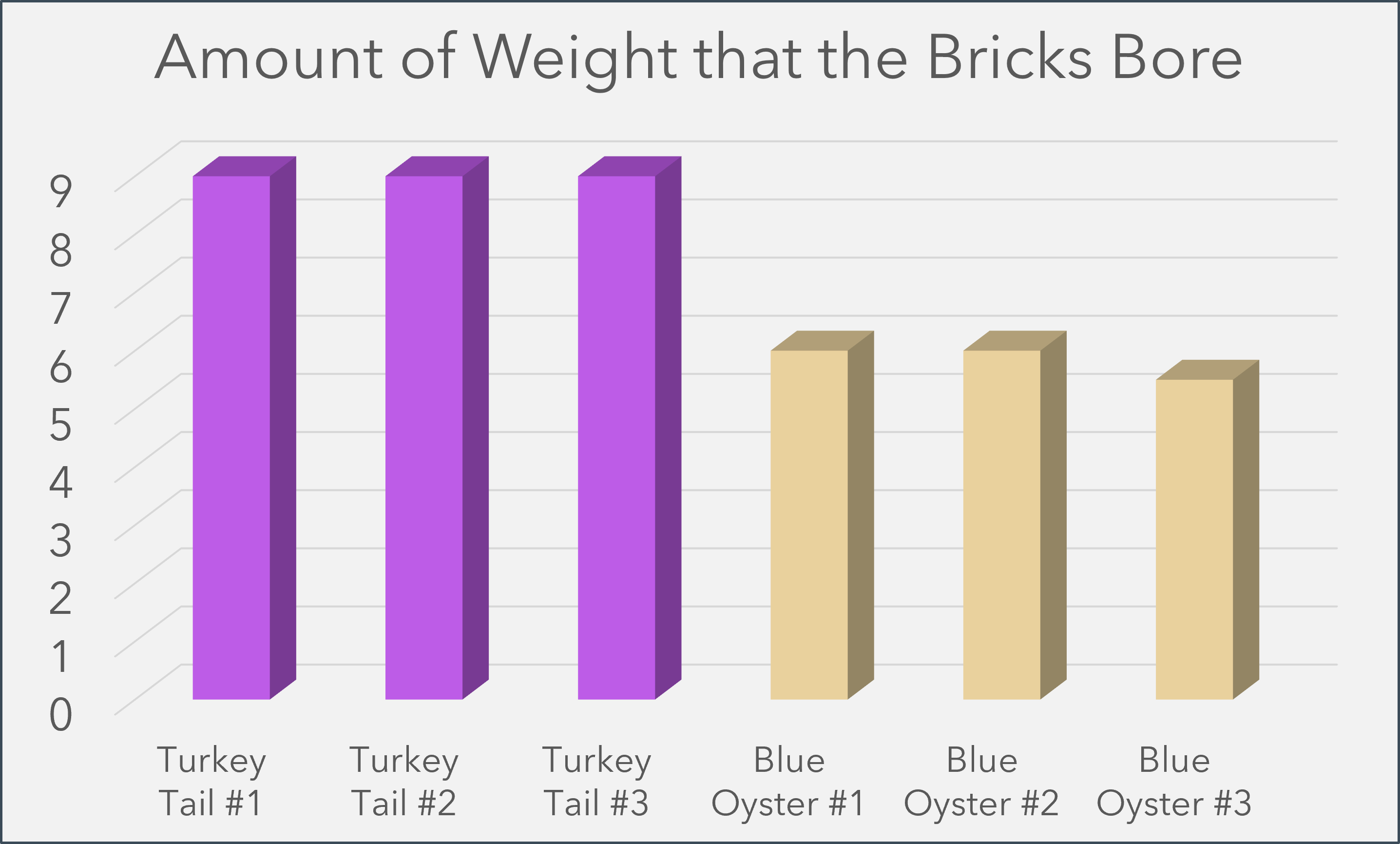

However, I felt there was some value in comparing the relative weight bearing capability of the different mycelium bricks. All the Turkey Tail bricks were able to hold over nine kilograms of weight. For one of the bricks, I attached the nine-kilogram weights for thirty minutes and the brick stayed intact! The Blue Oyster bricks could only support between five and a half and six kilograms of weights. From this, I concluded that the Turkey Tail bricks were able to hold at least 50% more weight than the Blue Oyster bricks could bear.

Below are a table and graph of my results.

Figure 14: Results from the Weight Capability test (Own Photo).

Mechanical Test 2: Water Resistance

For this experiment, I placed weights on the bricks to ensure that they were fully submerged. After over twelve hours of submersion, once I removed the weights, the bricks floated again.

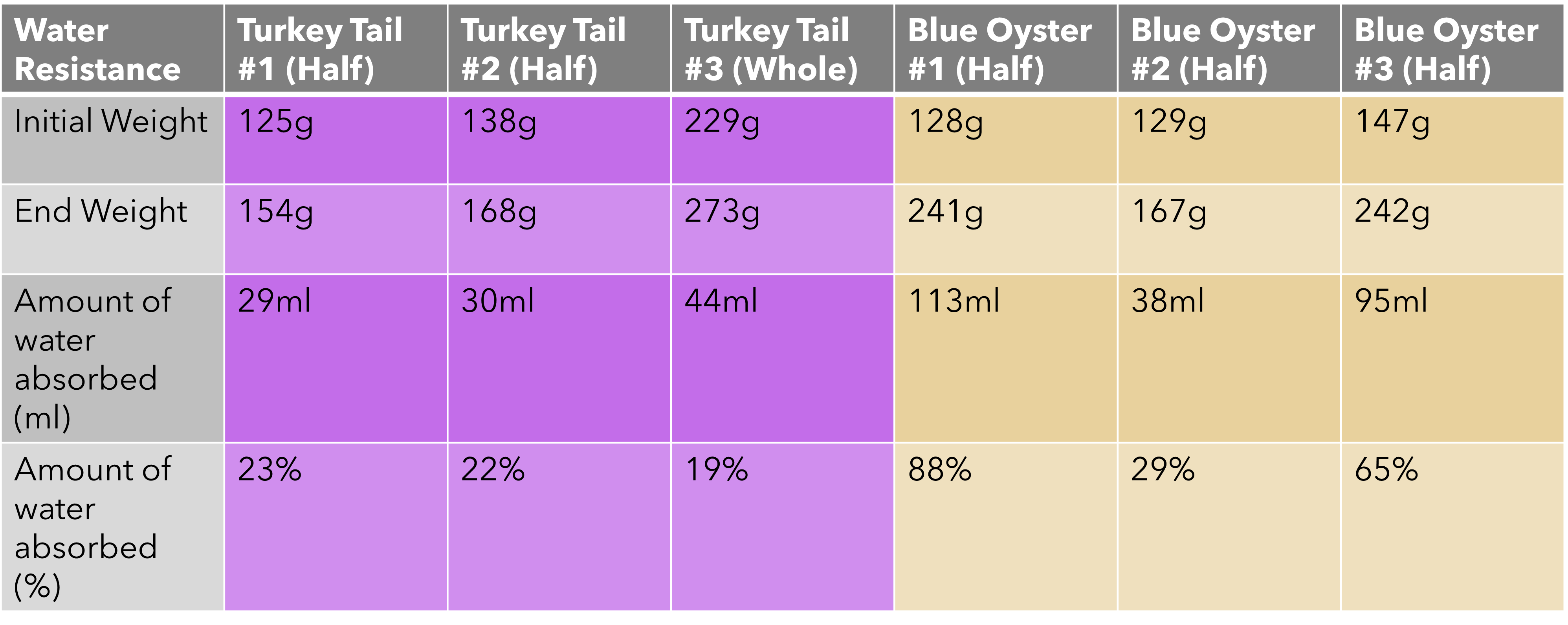

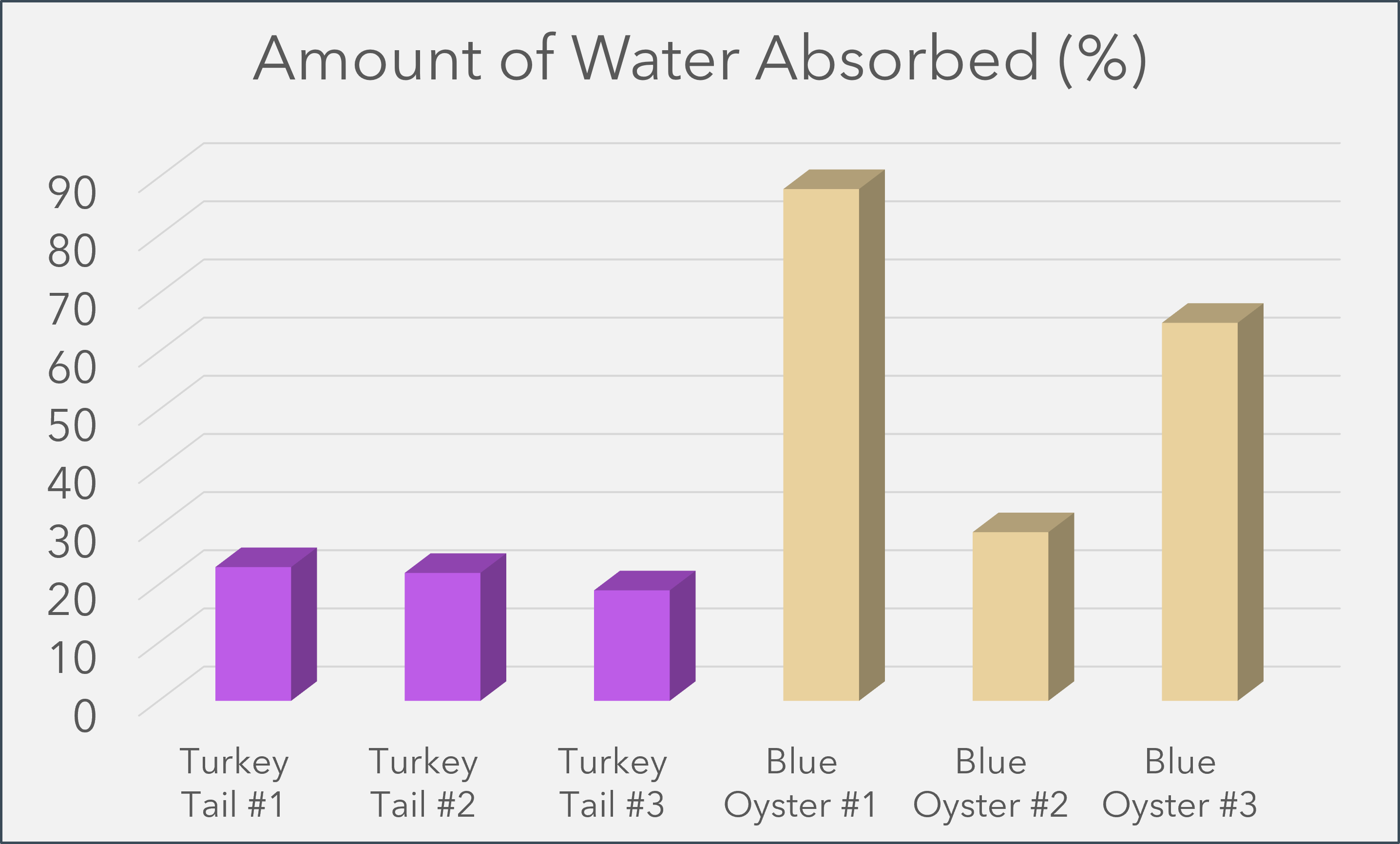

Industry allows bricks to absorb a maximum of 20% of their original weight. The bar graph below shows the percentage of their total weight of water that the bricks absorbed. Turkey Tail averaged at around 21.3%, while Blue Oyster averaged at 60.67%. Theoretically, this would mean that none of these bricks met the requirement. It is difficult to confirm if my results were accurate as the difference between the different Blue Oyster bricks was huge.

Figure 15: Results from the Water Resistance test (Own Photo).

There was some additional variability with my test. Since I used different sized bricks, there were differences in their surface areas. For example, two of the Turkey Tail bricks were cut in half, while one was kept whole.

Moreover, the Turkey Tail bricks developed a “leather-like” shell after a couple of days in their molds. For the two Turkey Tail bricks that were cut, the cut surfaces did not have that protective shell. These exposed surfaces would absorb water quicker than the surfaces where the protective shells remained.

Turkey Tail #3 brick, which was not cut, absorbed less water, percentage wise, when compared to the other Turkey Tail bricks.

From my results, it appears that the Turkey Tail bricks may meet the industry standard, however the Blue Oyster bricks will not.

Mechanical Test 3: Fire Resistance

My fire resistance test was simple and rather crude due to the lack of a controlled environment and the proper equipment. The tests took place outdoors where it was slightly windy, and after it had just rained.

None of the bricks caught fire, indicating that they were fire retardant.

Figure 16: Results from the Fire Resistance test (Own Photo).

Through these tests, I conclude that although mycelium bricks are strong, they do not meet the industry standard required for concrete bricks.

However, observations made from the tests revealed other interesting characteristics of mycelium. This will be covered in the next part of my report, where I discuss how mycelium can be a potential alternative to materials used today.

Application 1: Mycelium in the Construction Industry

There are many factors which contribute to Climate Change including the building and construction sector. This industry accounts for a staggering 37% of global emissions due to the use of materials like cement, steel, and aluminum (United Nations Environment Programme, 2023). According to the UN, there are three different strategies that can be taken to mitigate the carbon footprint from infrastructure.

-

Avoid unnecessary extraction and production.

-

Shift to regenerative materials.

-

Improve decarbonization of conventional materials.

After reading this article, I was intrigued by point two. There were claims online of mycelium being able to self-heal, so I performed a simple trial to verify this claim. I snapped two of my mycelium bricks in half and put the two halves of the brick next to each other for one month. One of these bricks was baked, and the other was not. I added a flour-water mixture in between the crack, keeping the area moist during the entire period. After the month, I noticed that the non-baked brick had begun repairing itself and the crack was less distinct. Here are the before and after images of the brick.

Figure 17: Before and after results of my self-healing trial (Own Photo).

After some further research, I found that the process of creating mycelium creates less greenhouse gases compared to more common materials (Alemu, Tafesse & Mondal, 2022). Thus, mycelium bricks can also lead to the decarbonization of conventional materials (point three).

Currently, there have been a couple of instances of mycelium products being used in the construction industry. For example, Ecovative, leader in mycelium-based products, built a tiny house insulated with only mycelium. The mycelium grew into the space within the walls over a few days, forming an airtight seal. After a month, the mycelium dried and became dormant, leaving an airtight wall that was extremely strong. This mushroom insulation method saves on material costs, as you do not need any studs in the wall, and it gives you great thermal performance since it is one continuous insulated wall assembly (Mushroom Tiny House, n.d.).

Figure 18: Showcase of the Mushroom Tiny House (Williams, 2013).

Compared to conventional insulation boards which are created from petrochemicals, these mycelium-based insulation boards are much more environmentally friendly (Taylor-Foster, 2014). Harsh flame resistance chemicals are used on conventional insulation boards to meet fire safety codes which have dangerous effects on the environment and our health (United Nations Environment Programme, 2017). These chemicals can be avoided since I found from my tests that mycelium was fire resistant. These claims were further collaborated by Ecovative, who also claims that their Mushroom® Insulation was fire retardant.

As a sea cadet and an avid sailor, I was interested to see if someone had built a mycelium-based floatation device. Washington State University student Katy Ayers built a 7.5-foot-long canoe using mycelium (Young, 2022). I am creating a much smaller mycelium boat to see if this would work.

Figure 19: The creator, Katy Ayers, on the “MyConoe” (Young, 2022).

Application 2: Mycelium in the Packaging Industry

When creating the bricks, I noticed that they were very light and moldable, prompting me to look at using mycelium in the packaging industry. Upon further investigation, I found out that IKEA, Canada’s biggest furniture retailer, decided to switch from styrofoam-based packaging to mycelium-based packaging (Barrett, 2020). According to Barrett, mushroom and other plant-based packaging uses a fraction of the energy required to make plastic and produces less carbon emissions. It also naturally breaks down into the Earth with minimal pollution, unlike plastic taking hundreds or thousands of years to break down.

Figure 20: Candle cup being placed in custom mushroom-based packaging (Barrett, 2020).

Joanna Yarrow, Head of Sustainability for IKEA in the UK, adds that “the great thing about mycelium is you can grow it into a mold that then fits exactly. You can create bespoke packaging.”

Figure 21: Wine bottle being packed in a custom-made mushroom-based styrofoam alternative (EcoWatch, 2016).

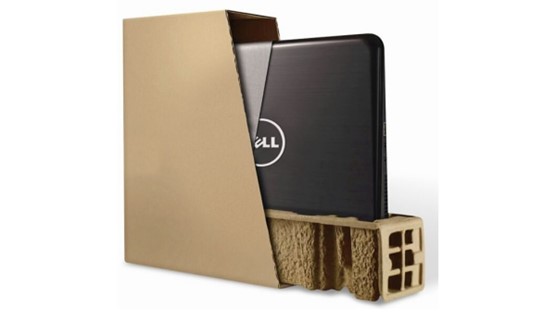

Mushrooms grown within a mold are also cushioning Dell products during shipping (McMahon, 2011). “The mushroom cushioning is unique because it is grown and not manufactured in the traditional sense,” said Oliver Campbell, Dell's senior packaging manager. Because it is grown, the new packaging requires 98% less energy to produce than foam packaging, and after it serves its purpose, customers can compost it. The ability to divert packaging from the waste stream reduces costs for businesses and individuals in cities like Calgary where waste removal charges are based on volume.

Figure 22: Dell laptop being packaged in a mushroom-and-bamboo-based carboard (EPE USA, 2019).

Application 3: Mycelium in the Apparel Industry

I noticed that the mycelium created from the Turkey Tail mushroom had a very tough outer protection shell. This material was very hard to rip and felt almost like “leather”.

Research reveals that it takes around seventeen-thousand liters of water to produce one leather tote bag. The liquid waste from the hide tanning process can also leach into local waterways, polluting the natural environment (Fairware, 2023).

Lululemon, a Canadian-American multinational athletic apparel company, have created designer bags with this new “leather-like” mycelial material (Hoshikawa, 2022). They used a material called Mylo developed by Bolt Threads to make these bags. "Mylo is made from renewable mycelium, the root structure of mushroom," states Dennis Wang, Lululemon's Vice President of Accessories Design. While cows require extensive resources and years to raise, the mycelium used to make Mylo is grown in less than two weeks inside a state-of-the-art vertical farming facility powered by 100% renewable electricity (Mylo, 2023).

Figure 23: Lululemon’s designer mushroom-based bags (Chua, 2021).

Figure 24: Mylo leather beside mushrooms (Hahn, 2020).

Adidas also partnered with Bolt Threads, creating a shoe using mushroom technology to honor former tennis player, Stan Smith. According to an article by Forbes, it took four thousand samples and one year of work with Mylo, to ensure not only the sustainability, but also the aesthetic and performance of a regular sneaker. “The introduction of Mylo as a new material is a major step forward in our bold ambition to help END PLASTIC WASTE”, said Amy Jones Vaterlaus, Global Head of Future at Adidas (Adidas, 2021).

Figure 25: Mylo shoes from Adidas (Haines, 2021).

Application 4: Mycelium in the Agriculture Industry

In 2021, Canada consumed 2.8 million tonnes of fresh meat (Agriculture and Agri-Food Canada, 2022). This comes out to a bit more than the weight of two hundred eighty-three Calgary Towers. According to an article written by NASA, about 21–37% of total greenhouse gas (GHG) emissions are attributable to the food system (Mbow, 2020, p. 439).

I found out that mycelium was being used in foods after visiting a new vegetarian restaurant in Calgary named Padmanadi. They served Indonesian cuisine and the food tasted amazing. It was fascinating that they used mushrooms to create the “fake meat” added to the dishes. Before eating at Padmanadi, the only vegan meat I had tasted were the “Beyond Meat” burgers at A&W. Those burgers had the taste of meat; however, the texture was best describable as mush. The “beef” at Padmanadi mimicked both the texture and the taste of beef. I could savor each individual strand of meat in my mouth, and it was such a delicious experience.

Figure 26: Mushroom-based steak (Bergo, 2017).

Moreover, I discovered MyForest foods, the creators of MyBacon. Because “fungi are fundamentally closer to animals than they are to plants evolutionarily,” the mushroom root can deliver the flesh-like texture and gristle bacon-lovers expect, says Eben Bayer, the co-founder and CEO of MyForest (Watson, 2023).

Figure 27: Mushroom-based bacon (Watson, 2023).

Application 5: Mycelium in the Furniture Industry

Did you know that the furnishings in your buildings contribute significantly to climate change. In fact, according to PEFC Furniture, the furniture sector is responsible for about 12% of all greenhouse gas emissions caused by humans, which has an annual impact of almost 13 million hectares of tropical forest. That would be the equivalent of losing an area of forest every year the size of England (PEFC, 2022).

Ecovative, creators of the mushroom house, and bioMASON, a company specializing in the creation of sustainable alternatives for consumer goods using a process called bio fabrication, unveiled their mushroom-based furniture at BioFabricate in 2016 (Sheikh, 2016).

Figure 28: Mushroom-based furniture (Sheikh, 2016).

They used the readily biodegradable mushroom material to create the base of the stools and the table legs. They harnessed the property of mycelium harnessing on different compounds to help with the growing process of this furniture.

I am currently creating a table using mycelium. For the last month, I had been cultivating mycelium from the Turkey Tail mushroom strain, after which I would pack the mycelium into a mold. Once the mycelium has colonized the substrate in the mold in a few weeks, I will assemble the table and present it at the in-person Calgary Youth Science Fair.

Sources of Error and Future Steps

Due to the lack of resources, I could only perform limited tensile strength, water, and fire resistance tests. There are many industry standards tests that commercial bricks need to go through to be considered “safe for use”. Based on my limited testing, the Turkey Tail strain showed some promise, leading me to believe that with better equipment, I would be able to get more reliable findings. I plan to seek the assistance of Southern Alberta Institute of Technology (SAIT) or the University of Calgary, to further investigate and understand the characteristics of these mycelium bricks.

Midway through the project, I discovered that I did not have adequate time to produce the necessary mycelium samples, nor the financial resources to procure the testing equipment necessary to complete my experiments. While I was able to repeat some of the experiments three times, there were some tests which I was only able to conduct once.

Aside from the flaws in the testing methodology mentioned in the analysis, my sterilization process was not consistent throughout the creation of my bricks, and the amount of time that the mycelium was in each of the different growing stages (inoculation jar, fruiting bags, mold, drying) differed. For example, I left the Turkey Tail in its fruiting bag for more than a month before using it to make bricks, but for the Blue Oyster, I only gave it around 2 weeks. Although this was based on the different cultivation periods needed for different mushroom strains, it was still a potential source of error. More experiments will be needed to investigate whether changing the period of cultivation for each strain of mushroom would change the characteristics of the associated mycelium significantly.

Since I only tested out two strains of mushrooms, I wish to test mushrooms strains that the Canadian public are more familiar such as shiitake, portobello, and button mushrooms. This way, the Canadian public would be able to better identify and link the benefits associated with mycelium-based products to the mushrooms that they are consuming.

Currently, I am creating a cup, boat, and table using mycelium. In the future, I intend to use these mycelium bricks to create a miniature house, exposing it to natural weather patterns in Calgary or Alberta, observing how the house would stand up.

Going forward, I would also like to investigate more uses of mycelium in the real world today and look into whether the processes are repeatable in different parts of the world too.

Conclusion

Conclusion

Mycelium based products can be grown quickly and affordably, making it a cost-effective solution for the world. Mycelium appears to also be more friendly to the environment than many other commercially available materials. The structure of bonded organic matter makes it easily degradable, leading to less waste while also promoting the development of healthy soil.

The ability of mycelium to be easily molded into the shapes of other objects is another strength. It is also light, which can lead to lower transportation costs. A byproduct of mycelium is mushrooms which is a popular nutritional product. With the advanced culinary techniques today, chefs can also convert mushrooms to mimic the texture and taste of meat.

Additionally, I feel that this amazing material can inspire other students to delve into more sustainable options in the fight against climate change. I am currently leading an environmental education program showing how we can use microbes to generate electricity. This program is currently rolled out to 6 schools in Calgary and Red Deer, empowering over 400 Grade 4 - 9 students. This amazing material made from another class of microbes can be integrated into that program.

In this report, I have showcased the versatility of mycelium by highlighting its uses in five different industries. Some of these projects are being funded by wealthy global corporations. With more research by both industry and academia, I am optimistic that mycelium will become a very potent alternative 21st century material.

Citations

Sources

Adidas. (2021, April 15). Stan Smith MyloTM: Made Using Mushrooms. Adidas CA; adidas. https://www.adidas.ca/en/blog/663481-stan-smith-mylotm-made-using-mushrooms

Agriculture and Agri-Food Canada. (2022, May 25). Customized Report Service – Canadian pork meat trends. Agriculture.canada.ca. https://agriculture.canada.ca/en/international-trade/market-intelligence/reports/customized-report-service-canadian-pork-meat-trends

Alemu, D., Tafesse, M., & Mondal, A. K. (2022). Mycelium-Based Composite: The Future Sustainable Biomaterial. International Journal of Biomaterials, 2022(8401528), 8401528. https://doi.org/10.1155/2022/8401528

Barrett, A. (2020, February 7). IKEA Replaces Styrofoam With Mushroom Bioplastics. Bioplastics News. https://bioplasticsnews.com/2020/02/07/ikea-styrofoam-mushroom-bioplastics/

Benjamin, D. (n.d.). Hy-Fi: Zero carbon emissions compostable structure, New York, NY. Holcim Foundation Website. https://www.holcimfoundation.org/projects/hy-fi

Bergo, A. (2017, July 29). The Beefsteak Mushroom. Forager | Chef. https://foragerchef.com/the-beefsteak-mushroom-fistulina-hepatica/

Casselman, A. (2007, October 4). Strange but True: The Largest Organism on Earth Is a Fungus. Scientific American. https://www.scientificamerican.com/article/strange-but-true-largest-organism-is-fungus/

Caucus Blog. (n.d.). What is the Mycelium and How Does it Impact Agriculture? The Caucus Blog. Retrieved March 12, 2024, from https://www.thecaucusblog.com/2023/10/what-is-mycelium-and-how-does-it-impact.html

Chua, J. M. (2021, July 7). Lululemon’s Mylo Mushroom Leather Collection. Sourcing Journal. https://sourcingjournal.com/gallery/sustainability/sustainability-news/lululemon-mylo-mushroom-leather-yoga-accessories-vegan-sustainable-bolt-threads-289320/

Corp, P. (2021, December 27). Canada records temperature below -51°C for the first time this season. The Weather Network. https://www.theweathernetwork.com/en/news/weather/forecasts/canada-records-temperature-below-51-c-for-the-first-time-eight-years

Daley, J. (2018, October 15). This Humongous Fungus Is as Massive as Three Blue Whales. Smithsonian Magazine. https://www.smithsonianmag.com/smart-news/mushroom-massive-three-blue-whales-180970549/

EcoWatch. (2016, March 4). IKEA Plans to Ditch Toxic Polystyrene for Biodegradable Mushroom Packaging. EcoWatch. https://www.ecowatch.com/ikea-plans-to-ditch-toxic-polystyrene-for-biodegradable-mushroom-packa-1882187596.html

EPE USA. (2019, November 29). Dell and its sustainable packaging – EPE Global. EPE. https://epe.global/2019/11/29/dell-and-its-sustainable-packaging/

Fairware. (2023, April 5). Vegan leather vs real leather for the merch industry. Fairware Promotional Products. https://fairware.com/vegan-leather-vs-real-leather-for-the-merch-industry/#:~:text=It%20takes%20about%2017%2C128%20litres

Hahn, J. (2020, October 8). Major fashion houses will sell products made from mushroom leather by next year. Dezeen. https://www.dezeen.com/2020/10/08/mylo-consortium-adidas-stella-mccartney-lululemon-kering-mycelium/

Haines, A. (2021, May 5). Fungi Fashion Is Booming As Adidas Launches New Mushroom Leather Shoe. Forbes. https://www.forbes.com/sites/annahaines/2021/04/15/fungi-fashion-is-booming-as-adidas-launches-new-mushroom-leather-shoe/?sh=56b50fd2788c

Hoshikawa, K. (2022, March 16). Lululemon’s First Mushroom Leather Gym Bag Is Here. Www.refinery29.com. https://www.refinery29.com/en-us/lululemon-mylo-gym-bag-review

Johnston, E., & Brewer, G. (2023, March 11). Mycelium: Exploring the hidden dimension of fungi | Kew. Www.kew.org. https://www.kew.org/read-and-watch/fungi-hidden-dimension

Litster, M. (2021, June 28). Mycelium: The Highway Under the Soil. Mayne Island Conservancy. https://mayneconservancy.ca/mycelium-the-highway-under-the-soil/

Mbow, C., Rosenzweig, C., Barioni, L., Benton, T., Frank, S., Kriewald, S., Lanigan, G., López, D., Spain, Mason-D'croz, D., Shukla, Skea, J., Calvo Buendia, E., Masson-Delmotte, V., Pörtner, H.-O., Roberts, D., Zhai, P., Slade, R., Connors, S., & Van Diemen, R. (2020). SPM 5 Food security Coordinating Lead Authors: Lead Authors. https://ntrs.nasa.gov/api/citations/20200001724/downloads/20200001724.pdf

McMahon, J. (2011, May 11). Dell To Grow Mushroom Packaging For Its Servers. Forbes. https://www.forbes.com/sites/jeffmcmahon/2011/04/05/dell-to-grow-mushroom-packaging-for-its-servers/?sh=21e5207a5ca6

Meati. (n.d.). Good Energy for Everyone | Meati Foods. Meati. https://meati.com/

Mushroom Tiny House. (n.d.). Mushroom Tiny House. Mushroomtinyhouse.com. https://mushroomtinyhouse.com/

Mylo. (2023). Meet MyloTM. MyloTM | Unleather. https://mylo-unleather.com/

NASA. (2022, January 29). World of Change: Global Temperatures. Earth Observatory; NASA Earth Observatory. https://earthobservatory.nasa.gov/world-of-change/global-temperatures

PEFC. (2022, February 9). Can Tables and Chairs Help Combat Climate Change? Furniture.pefc.org. https://furniture.pefc.org/the-furniture-blog/can-tables-and-chairs-help-combat-climate-change#:~:text=In%20fact%2C%20the%20furnishings%20industry

Sheikh, K. (2016, November 30). Now you can buy gorgeous furniture made of mushrooms. Popular Science. https://www.popsci.com/furniture-made-from-mushrooms-could-be-in-your-future/

Souza, E. (2020, October 12). Mushroom Buildings? The Possibilities of Using Mycelium in Architecture. ArchDaily. https://www.archdaily.com/949007/mushroom-buildings-the-possibilities-of-using-mycelium-in-architecture

Taylor-Foster, J. (2014, February 9). Insulation Grown From Fungi. ArchDaily. https://www.archdaily.com/473052/insulation-grown-from-funghi

United Nations Environment Programme. (2017, October 5). Flame Retardants. UNEP - UN Environment Programme. https://www.unep.org/topics/chemicals-and-pollution-action/pollution-and-health/persistent-organic-pollutants-pops/flame#:~:text=Flame%20retardants%20listed%20in%20the

United Nations Environment Programme. (2023, September 12). Building Materials And The Climate: Constructing A New Future. UNEP - UN Environment Programme. https://www.unep.org/resources/report/building-materials-and-climate-constructing-new-future

Watson, E. (2023, June 6). Meat from mycelium: MyForest Foods raises $15m Series A-2, hires new CEO, teases new product. AgFunderNews. https://agfundernews.com/my-forest-foods-raises-15m-in-series-a-2-funding-hires-new-ceo

Weinraub, M. (2022, May 20). This Plant-Based Brand Is Launching a New Steak — And It’s Ridiculously Amazing. Kitchn. https://www.thekitchn.com/meati-foods-classic-steak-review-23376560

Williams, A. (2013, July 11). Mushroom Tiny House: The part-grown portable home. New Atlas. https://newatlas.com/mushroom-tiny-house/28248/

Young, C. (2022, February 15). A 7.5-feet-long mushroom canoe demonstrates the powerful versatility of mycelium. Interestingengineering.com. https://interestingengineering.com/innovation/75-feet-long-mushroom-canoe

Acknowledgement

Acknowledgements

Dr. Tatenda Mambo, Ph.D., Professor, Department of Earth Sciences, University of Calgary

Heather Lai, Teacher, Westmount Charter Mid-High School, Westmount Charter Board

I would also like to thank my family (dad, mom, brother, sisters) for their help on my project.