Algae Bioplastics

Grade 7

Presentation

No video provided

Hypothesis

If I make two different bioplastics from algae, using tapioca starch in one, and agar agar in another, then the one make with starch will be able to bend more, and the one made with agar agar will absorb more water, because the agar agar will make the bioplastic harder, but it can also still absorb more water, since agar agar is able to absorb up to twenty times its weight in boiling water, and the bioplastic mixture probably won't come to a boil in 5 minutes.

Research

Conventional plastics:

- made form non-renewable materials

- produces greenhouse gasses when made

- long lasting

- dont break down easily and pollute the Earth

Bio-plastics:

- break down easier

- can be made from renewable and non-renewable materials

- produce less greenhouse gasses when made

- improves soil quality once broken down

Algae:

- a unicellular(only one cell) lifeform that grows with light and carbon dioxide

- makes oxygen like other plants

Algal blooms:

- overgrown algae is called an algae or algal bloom

- bad algal blooms contaminate water

- big algal blooms can produce toxins that kill fish, mamals, birds, aquatic life, and can make humans very sick

- thick or big algal blooms can clog fish gills and block light from getting to other aquatic plants

- they take water from the ocean as they decay

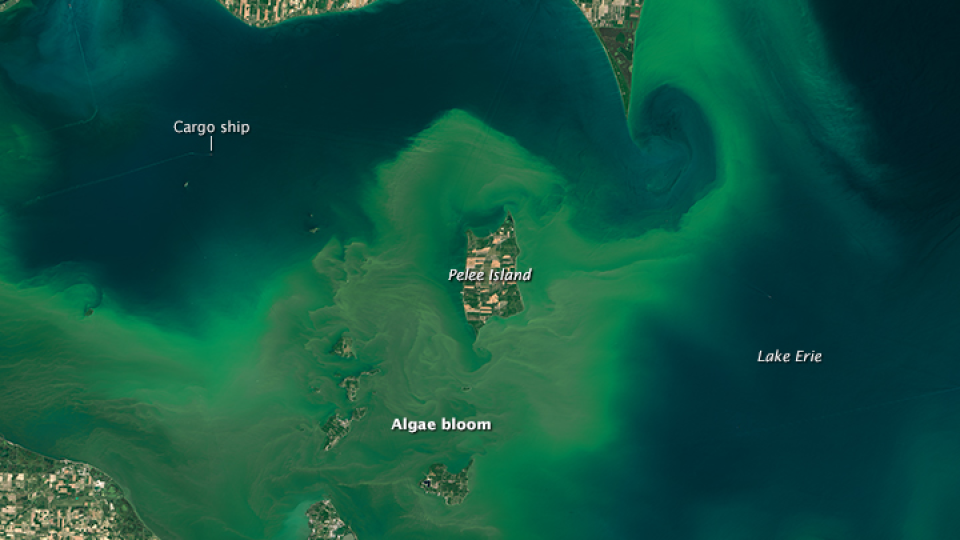

- there is a harmful and toxic algae bloom in Lake Erie

Plasticizers:

Glycerine: 95% glycerol (humectant, solvent, and thickening agent)

(all found on amazon)

Agar agar:

- can get up to 20x its original weight after being in boiling water

- similar to gelatin

- thickening and stabilizing agent for foods

Tapioca starch:

- high absorbancy rate

- thickening agent but weaker than agar agar

Variables

Manipulated: Method of creating algae bioplastics

Controlled:

- Plastic thickness

- Drying time

- Temperature

- Plastic sample size

- Plastic weight

- Quality measuring techniques

- environment

responding: Qualities of algae bioplastics

Procedure

Parchment Paper Box:

- Clean workspace

- Get parchment paper, scissors, ruler, and tape

- Cut out a 16 x 29cm rectangle from the parchment paper

- Use a pencil to mark a line 2 cm away from the edges on all sides. This will make a square shape on each corner

- Cut one of the lines on each square shape

- Fold the parchment paper on the lines

- Tape the corners together so the parchment paper resembles a rectangle with walls.

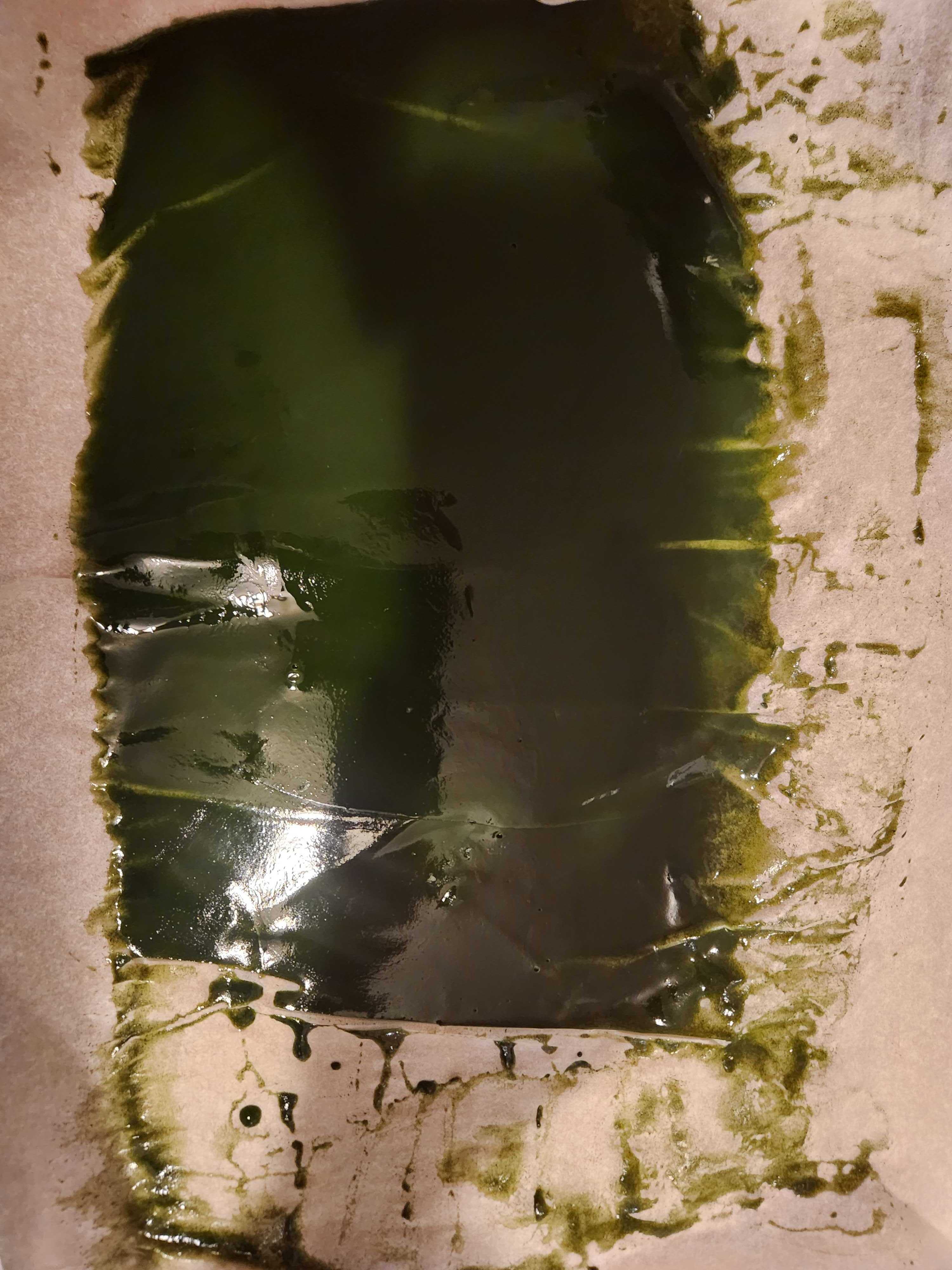

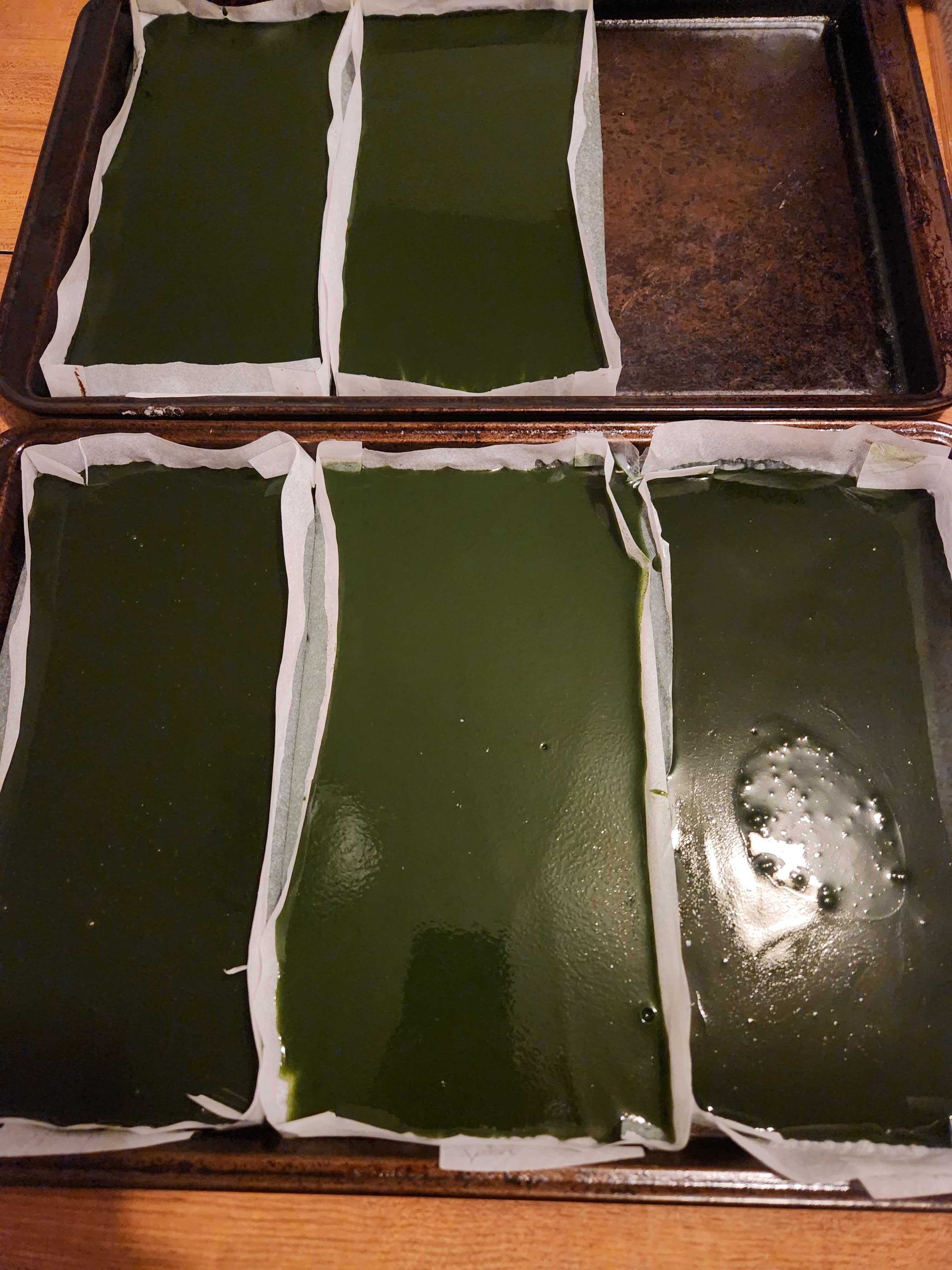

Atempt 1: Atempt 2:

(Chlorella powder found on amazon as a food)

Agar Agar:

- Gather materials

- Pour one cup of water into a pot

- Add two teaspoons of chlorella powder, one teaspoon of agar agar powder, and one teaspoon of glycerine to the pot

- Stir using spatula until combined

- Keep stirring over medium heat until mixture comes to a simmer and agar agar powder looks like it’s dissolved(5-6 mins)

- Put a parchment paper box on baking tray and pour all of the mixture over it so it covers the entire parchment paper box

- Store in cool, dry space and wait to dry(about 12 hours)

Tapioca Starch:

- Gather materials

- Mix one cup of water with two tablespoons(since agar is stronger than starch) of tapioca starch into a pot until there are no more lumps

- Add two teaspoons of chlorella powder and glycerine to mixture

- Mix over medium heat until mixture thickens

- Pour mixture into baking tray with parchment paper box

- Smooth out with a spatula so it covers the whole parchment paper box

- Store in cool, dry space and wait to dry(about 14 hours)

Testing:

(I used A.I to help brainstorm ideas for what qualities I should test the bio-plastics for and to ensure the recipie I used would work if I used agar agar and starch)

Water Absorption:

- Measure weight of one strip of bioplastic

- Place one strip of bioplastic into clear container

- Pour one cup of water into container

- Observe every 5 mins

- Every 5 mins, carefully take bioplastic out, and measure and record weight for 30 mins

- After 30 mins, take out bioplastic, weigh one more time, and record weight

- Repeat with each bioplastic variation twice

Flexibility:

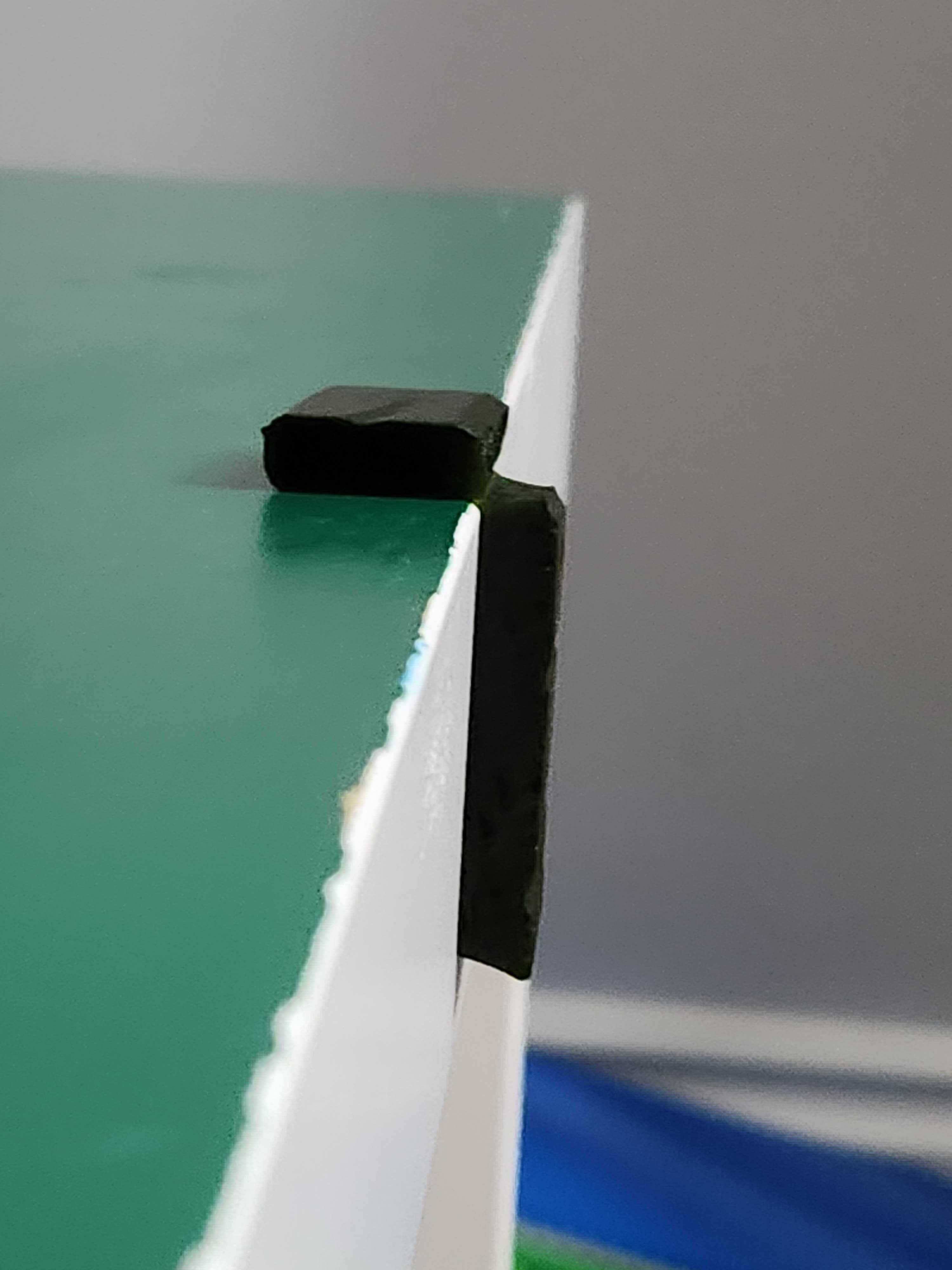

- Hold one bioplastic strip over side of table by one centimeter

- Continue to push bioplastic over side of table one centimeter at a time, using protractor to record how much plastic bends each time

- Stop when only one centimeter remains on table, or when plastic breaks

- Repeat with both types of bioplastic, twice

- Repeat with wet bioplastics from water absorption

Final Steps:

- Find average of water absorption, flexibility, and tensile strength for each plastic

- Clean workspace

- Form conclusion based on results of experiment

Observations

- While being heated in the pot, both plastics smelled like broccoli and unsalted, dried seaweed.

- The starch was lighter than the agar mixture while in the pot, but after they both dried, the agar mixture was lighter and the starch mixture was darker.

- The starch mixture took about 2 more hours to dry than the agar mixture, because in about 12 hours after leaving the plastics to dry, the agar mixture was completely set while the starch mixture was still like jelly, but in 2 hours, the starch mixture was a lot more firm.

- After being soaked in the water for 30 minuites, the agar bio-plastic was a lot softer, and the edges looked slightly transparent while nothing changed about the starch bio-plastic exept for gaining a gram, but both of them got alot slipperier.

- While doing the flexibility tests, i was only able to hold the bioplastic over the edge by 5cm once, because all the other times it fell off, but i didnt count that since none of the other plastics got measured at 5cm over the table during a flexibility test.

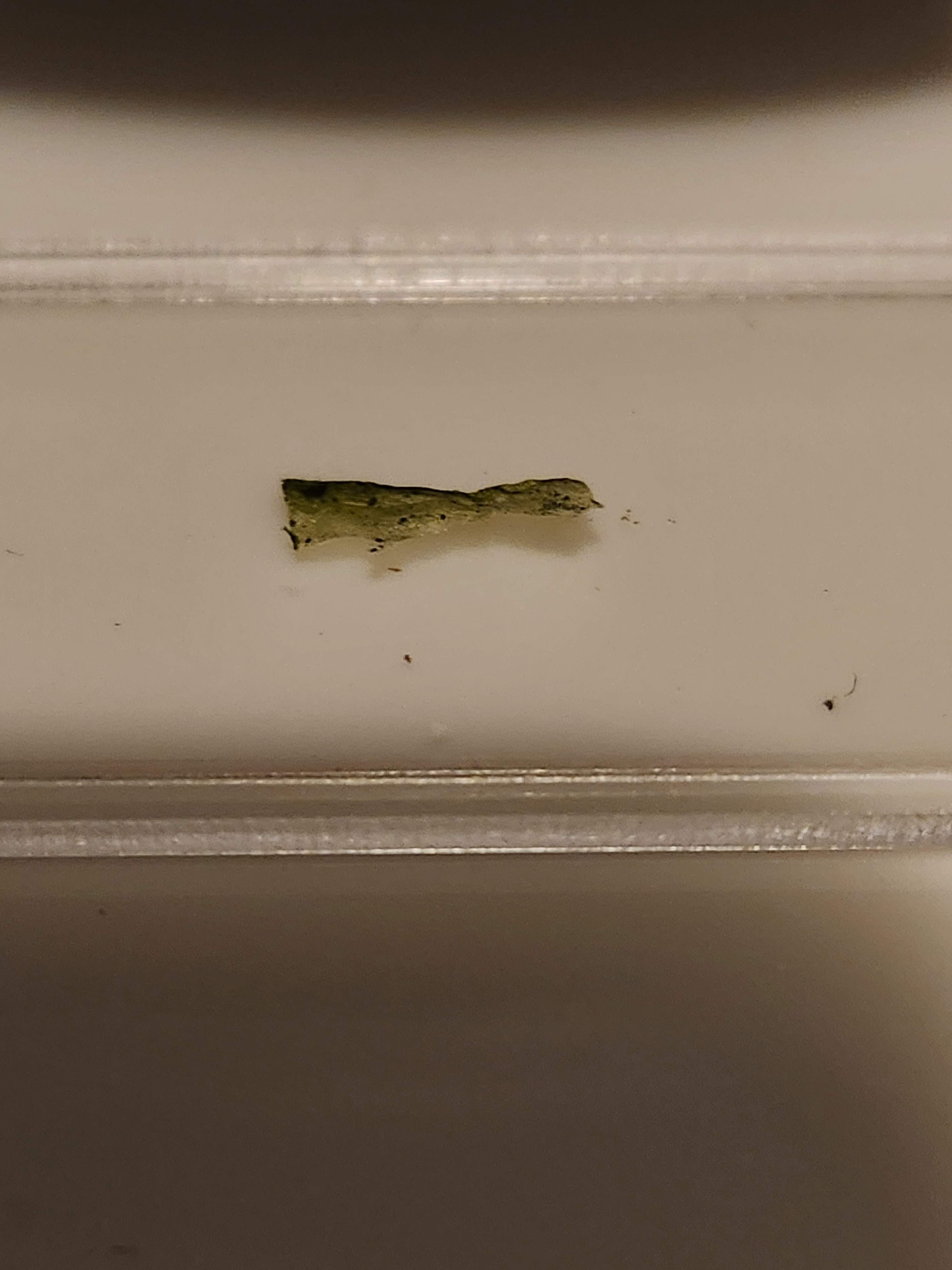

- On the second test for the starch bioplastics, after i moved the plastic strip 4cm off the edge of the table, it broke in half right where it lost contact with the table.

- Inside of the plastic, where it broke in half, it was mostly smooth, but had some small bumps in it.

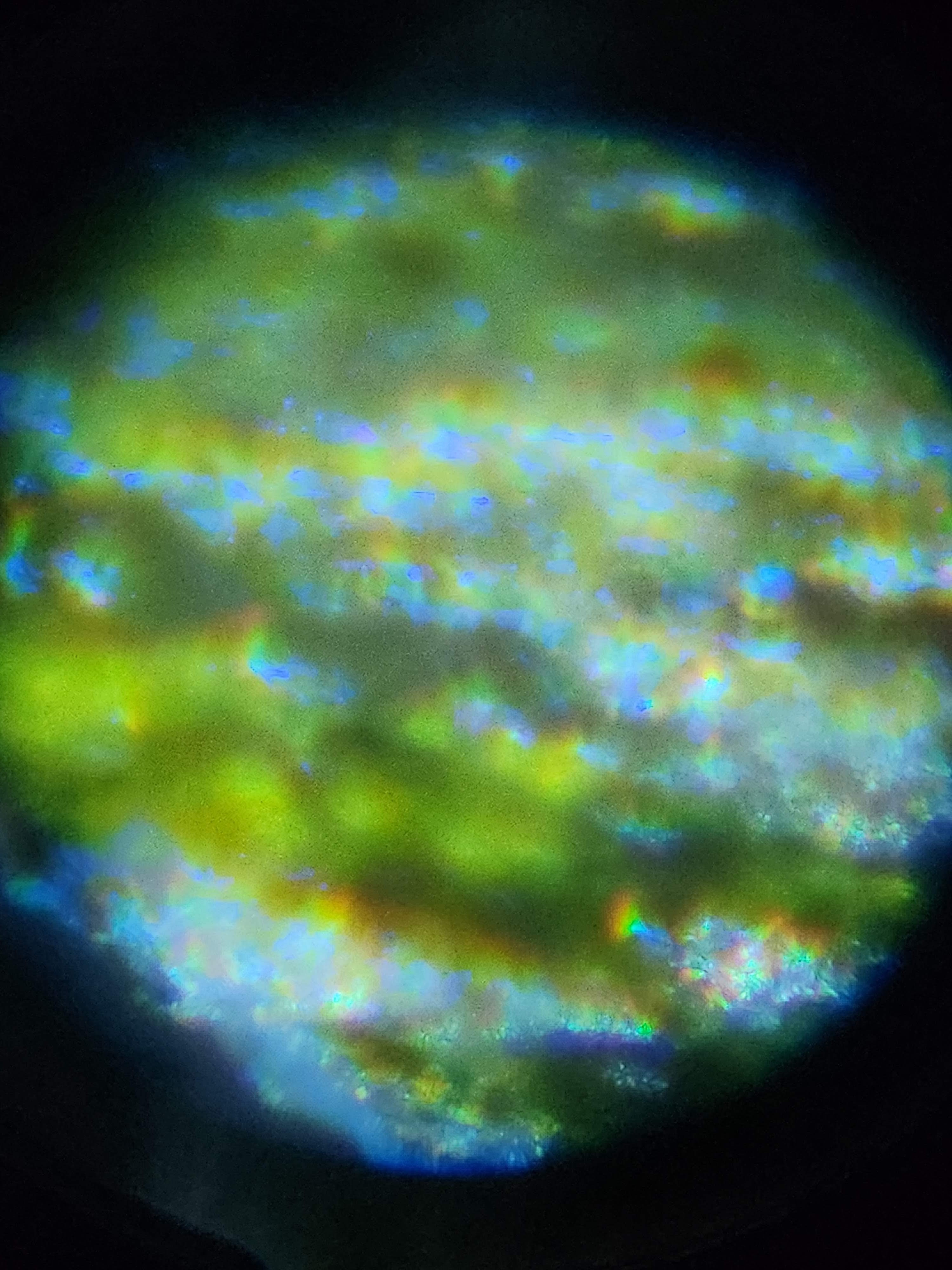

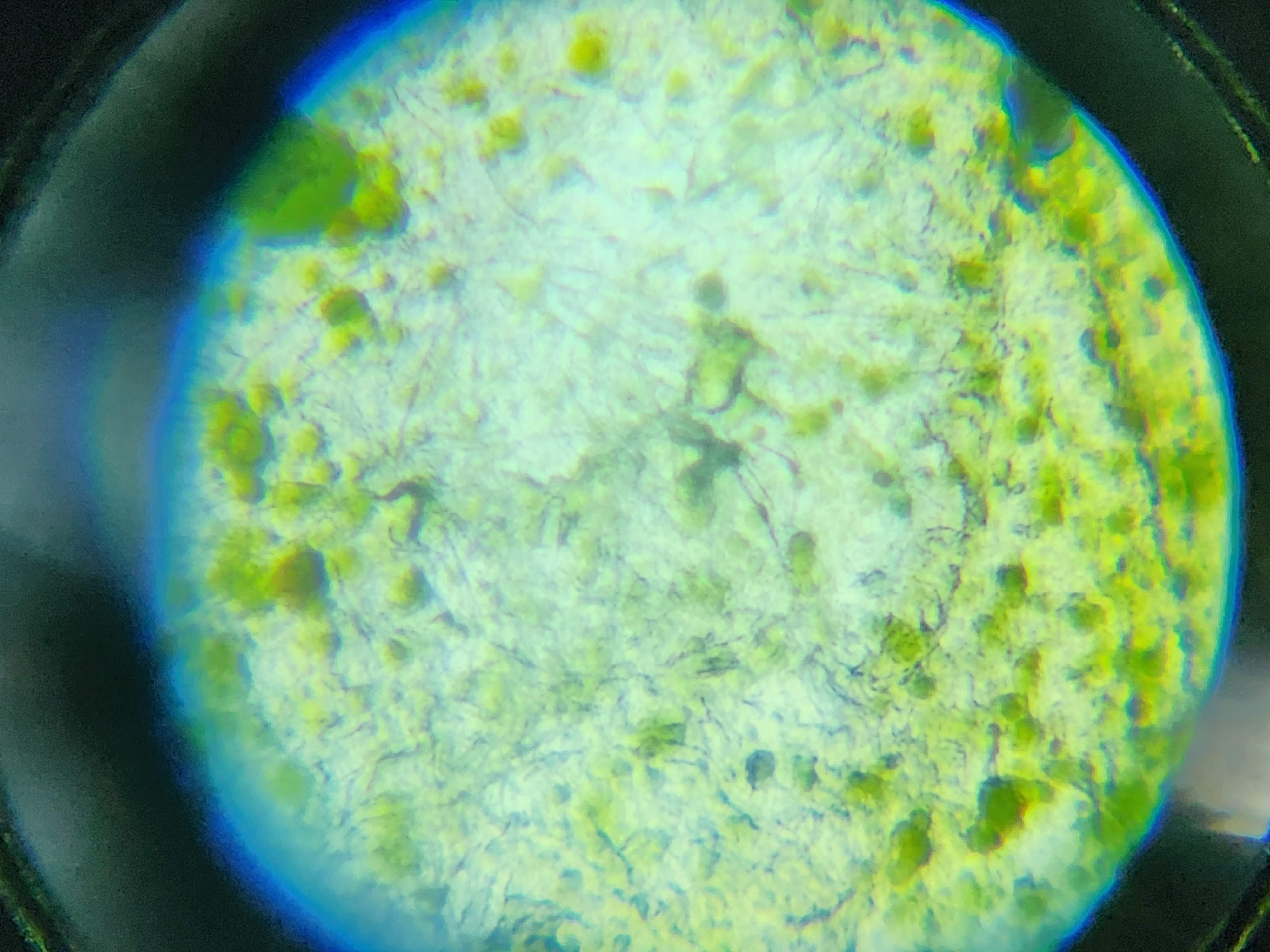

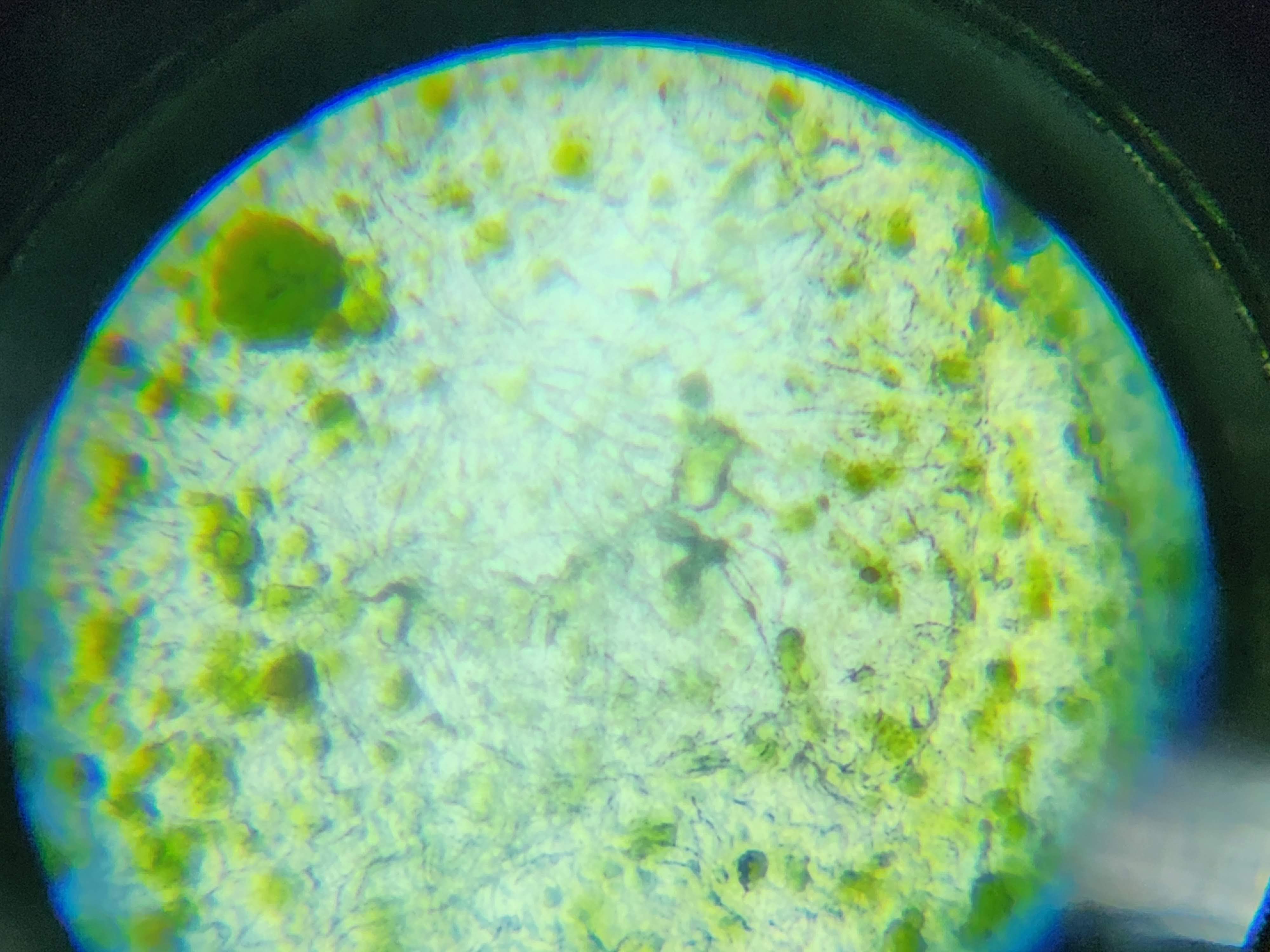

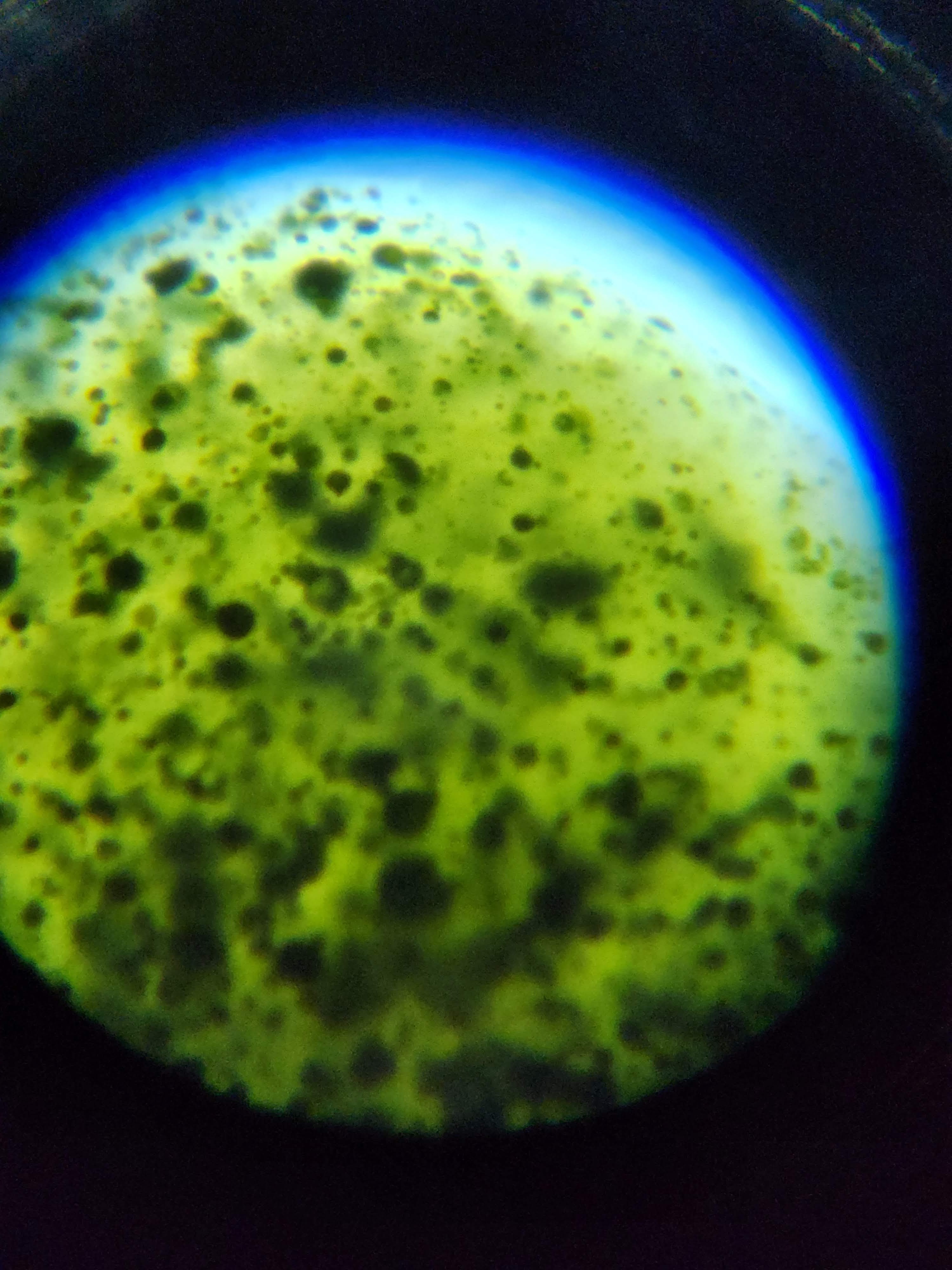

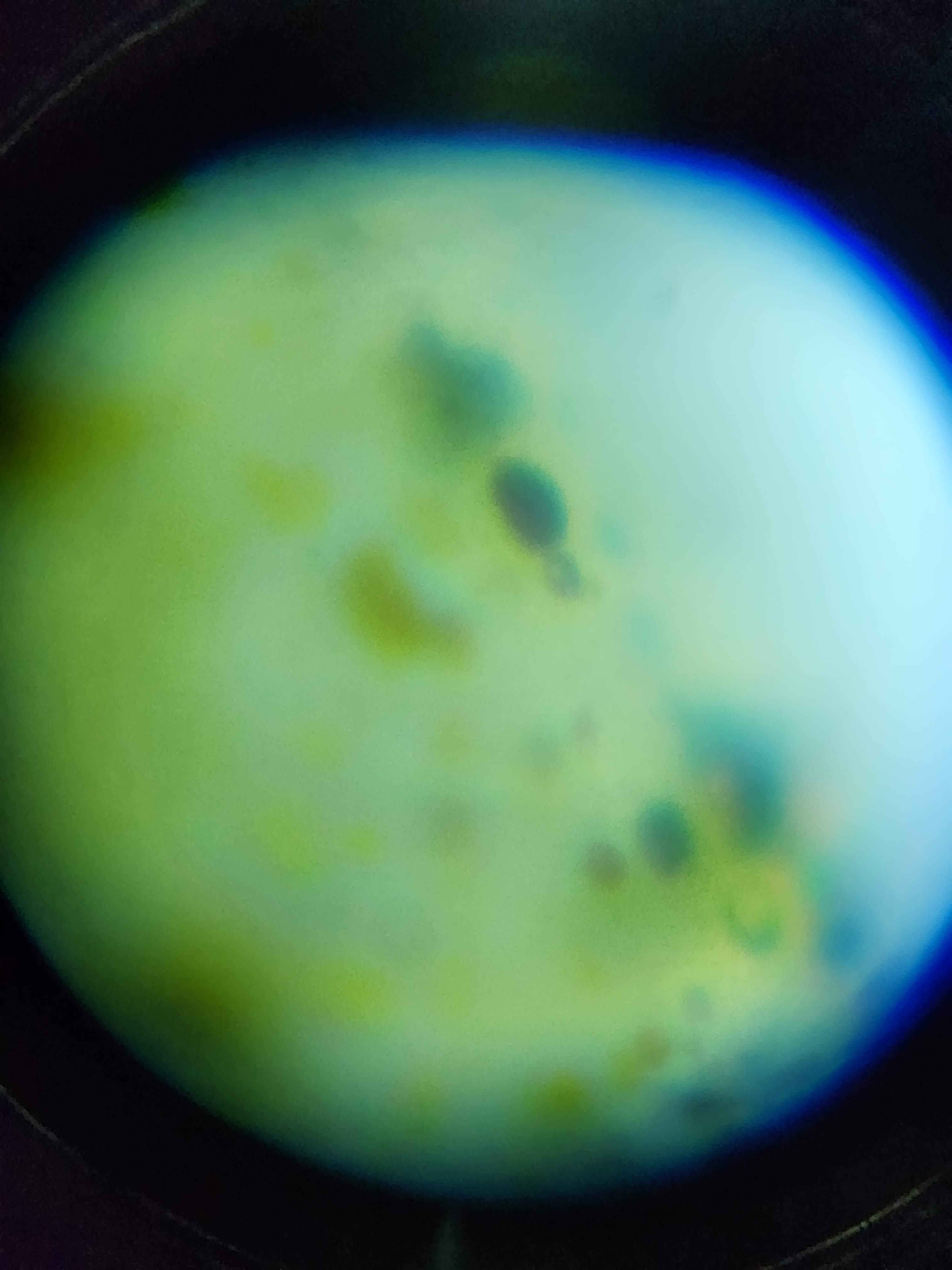

Under Microscope:

Agar:

Starch:

Analysis

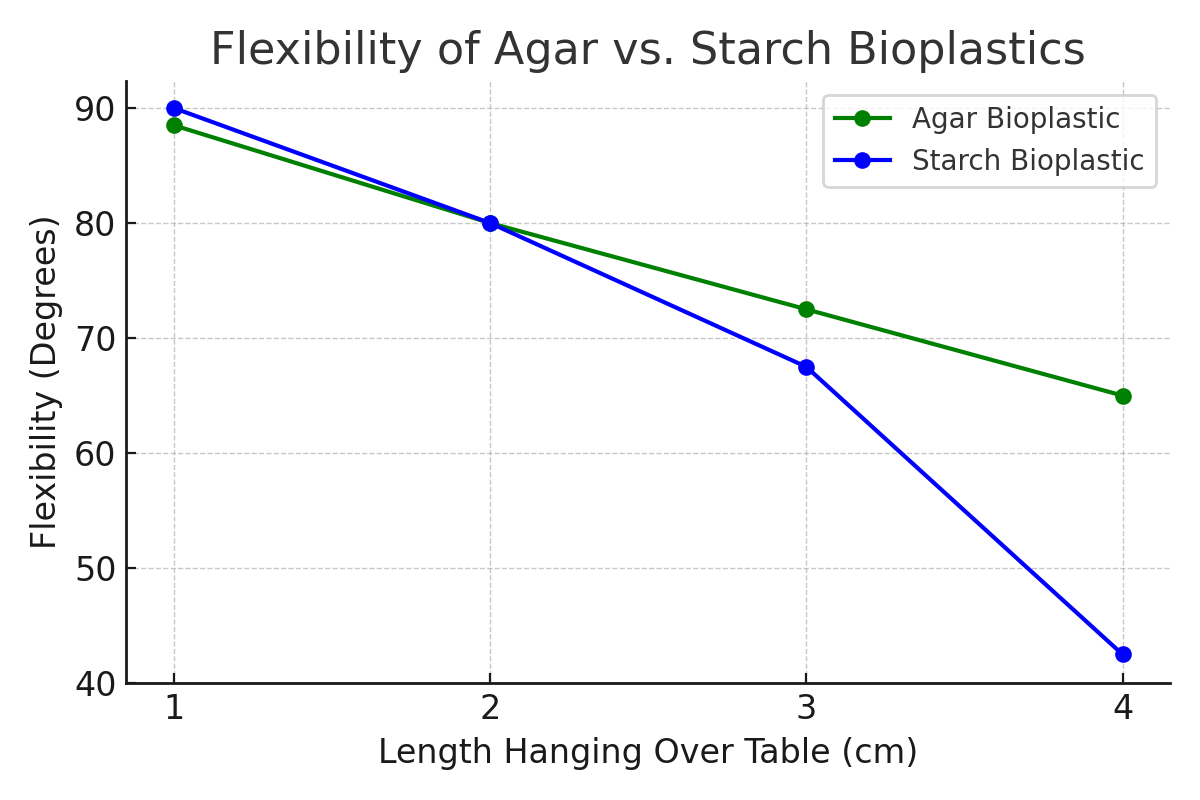

Flexibility tests:

Agar Agar (average):

1cm: 88.5° 2cm: 80° 3cm: 72.5° 4cm: 65°

Tapioca Starch (average):

1cm: 90° 2cm: 80° 3cm: 67.5° 4cm: 42.5°

Water Absorption Tests:

Agar Agar: (original weight is 7 grams)

(Test 1) 5 mins: 7g, 10 mins: 7g, 15 mins: 8,g 20 mins: 8g, 25 mins: 8g, 30 mins: 8 (Test 2) 5 mins: 8g, 10 mins: 8g, 15 mins: 8,g 20 mins: 8g, 25 mins: 8g, 30 mins: 8

Tapioca Starch:

5 mins: 8, 10 mins: 8, 15 mins: 8, 20 mins: 8, 25 mins: 8, 30 mins:8

Flexibility Test (using soaked plasics from the water absorption test):

Agar Agar (average):

1cm: 89.5° 2cm: 80° 3cm: 74.5° 4cm: 65°

Tapioca Starch (average):

1cm: 90° 2cm: 80° 3cm: 75° 4cm: 60°

Conclusion

In conclusion, the starch bioplastic could bend the most in all the flexibility tests with an average of 60 degrees after being soaked, and 42.5 degrees when it was dry, while the agar plastic bent 65 degrees while it was wet, and dry, so my hypothesis was right about the flexibility test, but for the water absorption test, the first agar plastic I tested gained one gram after 20 minuites, while every other plastic sample gained one gram after 5 minuites; changing it from 7 grams, to 8 grams. So my hypothesis was incorrect about the water absorption test.

Application

It's important to think about the problems we're facing now, and how our actions could effect the future. Right now, some problems we're facing are plastic pollution, and toxic algae blooms. By removing algae and using it to produce biodegradable plastics, we could be solving both of those problems for the future since less algae would mean there would be less toxins, and instead of throwing away plastic that will last decades, we could use the bio-plastics to improve our soil quality after they've been used and and are decaying. These bio-plastics could probably be used for anything in place of conventional plastics that doesnt need to be long lasting, in the water, or in heat unless someone finds out how to make it resistant from those things while still making sure it would be biodegradable. Some examples of what it could be used for are plastic containers used to hold fruits in a shop, plastic utensils, and plastic water bottles. My project could be helpful to anyone who wants to learn about toxic algal blooms, plastic polution, and bioplastics, anyone who wants to crreate a bioplastic, and people trying to solve the problems of pollution and algal blooms, or who are already making and using bio-plasics made from algae.

Sources Of Error

When I needed to test the bioplastics, they were still a bit like jelly, so I’m not sure if it could have dried anymore or gotten any harder or not, and while making them, the mixture was too dark for me to be completely sure the agar or starch had been mixed in properly, so that could have also affected the results, and also, I couldn’t get the bioplastics' thickness the exact same either, but I made sure they all weighed the same.

Citations

Online Sources:

- What is a harmful algal bloom?

- https://www.bpf.co.uk/plastipedia/how-is-plastic-made.aspx#:~:text=Plastic%20can%20either%20be%20'synthetic,bacteria%20and%20other%20biological%20substances.

- Bioplastics and conventional plastics: comparative analysis

- https://www.sciencedirect.com/topics/chemistry/biodegradability#:~:text=Biodegradability%20is%20the%20capacity%20for,methane%2C%20basic%20elements%20and%20biomass.

- https://www.e-education.psu.edu/egee439/node/696#:~:text=Algae%20can%20be%20harvested%20using,allowed%20to%20settle%20and%20densify.

- https://en.wikipedia.org/wiki/Glycerol

- https://www.britannica.com/topic/gelatin

- https://www.thespruceeats.com/what-is-agar-agar-p2-1000960

- https://en.wikipedia.org/wiki/Tapioca

Videos:

Acknowledgement

I would like to thank my family for reading over my work to check for errors, helping me take pictures, and supporting me while doing my project, as well as my classmates and my teacher, Mrs.Turner, for asking questions that made me think more about my project.