Flaming PJ Madness

Amare Lakhani

Grade 5

Presentation

Hypothesis

I think that the more we wash the piece of fabric, the more flammable it will be. This is because if we wash the fabric multiple times, the fire resistant chemicals will be washing off from the washer and dryer causing it to be less flame resistant. I think the chemicals wash off in the water because they are dissolving and they come off the fabric. So if we wash a fabric more, it will have more scorch area.

It is important to research about this topic because other people would use that when buying pajamas. They would look if the pajamas would stop getting fire resistant, the more we wash it. It is also important to research if the pajamas could cause harm to health because of the flame resistant chemicals.

Research

Fabrics that have been treated with flame retardants are usually certified for one year or for 50 washes. If you wash them in your washing machine like any other fabrics the chemicals weaken over time, which is a good argument for talking about the safety of these fabrics.

Trained professionals worry that flame retardants have chemicals that can lead to cancer, neurotoxicity and hormone disruption (hormones are disrupted from doing their task)

Laundry water washes off flame retardants and it can go into the lakes and rivers (laundry is the main source of the retardants in the water) and affect animals and fish in the water

People may be exposed directly to the flame retardants by the chemicals directly on their clothes.

Child sleepwear regulations

In 1972, for five years, rules were in place that required children’s Pajamas to be flame resistant.

They used Brominated tris but then it was replaced with chlorinated tris, because children were exposed to carcinogens in their sleep through exposure in the skin.

Carcinogens are chemicals that may cause cancer.

Chlorinated tris was also bad because it was found to affect DNA.

Until 1996, natural fibres were only considered flame resistant if they were treated with flame retardants. Rules changed to allow tight fitting pjs since they are less likely to catch fire than baggy clothing.

In Canada and the US, require pjs for children 9 months old to 14 years old must meet flammability requirements or tight fitting.

Canada laws: There should be a label on loose fitting pjs that state flame retardant with instructions with cleaning procedures.

We should not use fabric softener because it separates the fibres which makes them soft, but then it takes away the fire retardants.

There is a common misconception that polyester is flame resistant because its plastic, unlike other fabric material polyester doesn’t burn, it melts without fire retardants.

-since polyester melts instead of burns while its on someone’s body and melts on it that would be super painful to feel and a painful surgery to get

The United States PJs with flame retardant added must be done on manufacture then fabric after 50 washes, however, in Canada after 20. This means that washing fire resistant fabric is not an effective solution to reducing exposure to fire resistants.

Of note, in the US, flammability tests on products with flame retardants added must be done on fabric after manufacture and after 50 washes, in Canada after 20 washes. Which means that washing treated PJs isn’t an effective solution to reducing exposure to flame retardants.

Loose fitting sleepwear is more likely to catch on fire than tight fitting sleepwear.

If your child wears loose fitting sleepwear make sure it is made of slower burning fabrics. Cotton-blend and rayon fabrics tend to catch fire and burn more quickly than most synthetic materials. Nylon and polyester do not catch fire as easily as cotton does and they tend to burn more slowly.

Government of Canada testing requirements: an average char length for 5 specimens that does not exceed 178 mm; and not more than one specimen with a char length equal to the full length of the specimen.

Loose-fitting sleepwear — other tests

Loose-fitting sleepwear that is treated with a flame retardant, any component that is extracted or broken down from such treated sleepwear and any flame retardant that is used to treat the sleepwear must not cause any of the following consequences:

- acute lethality as a result of oral exposure to a dose of 500 mg/kg body weight or less or as a result of dermal exposure to a dose of 1000 mg/kg body weight or less when tested for acute oral toxicity or acute dermal toxicity in accordance with section 1 or 2, as the case may be, of Schedule 2;

- an effect graded at a mean greater than 1 for erythema formation or for edema formation measured at any specified time when tested for dermal irritation in accordance with section 3 of Schedule 2;

- when tested for dermal sensitisation in accordance with section 4 of Schedule 2, a response in greater than 15% of the test animals when using the Draize Test or the Buehler Test or in greater than 30% of the test animals when using one of the five other tests, in which an adjuvant is incorporated, that are specified in the OECD Test No. 406 that is referred to in that section;

- gene mutation or chromosomal aberration when tested for mutagenicity in accordance with section 5 of Schedule 2; or

- tumors when tested for tumorigenicity in accordance with section 6 of Schedule 2.

Labeling

Loose-fitting sleepwear that is treated with a flame retardant must have a label that is permanently affixed to it that displays in a clear and legible manner:

the words “flame retardant” and “ignifugeant”; and

instructions in English and in French for the care of the sleepwear, particularly cleaning procedures, to ensure that it is not exposed to agents or treatments that could reduce its flame resistance.

Washing, drying and drycleaning

Loose-fitting sleepwear that is treated with a flame retardant must be subjected to 20 successive washing cycles in accordance with the procedure set out in section 3, followed by one drying cycle in accordance with the procedure set out in section 4.

The apparatus and washing procedure set out in sections 4.1 and 6, respectively, of Method 58, the National Standard of Canada CAN2-4.2-M77, Colour Fastness and Dimensional Change in Domestic Laundering of Textiles, published by CGSB in December 1984, must be used, with the following modifications:

The temperature of the wash water must be maintained between 58°C and 62°C; or 52 to 62 (different websites)

The hardness of the wash water must be less than 50 ppm of calcium carbonate;

for automatic washing machines, the washing cycle must be set for normal washing cycle;

A synthetic detergent that conforms to CGSB standard 2-GP-115M, Standard for Detergent, Laundry, Powder, Built, dated January 1979, must be used; and

A bleaching agent containing sodium hypochlorite that produces 0.015% of available chlorine when it is added to the washing solution must be used.

Variables

Manipulated variable: The amount of times a sample is washed.

Responding variable: What percentage of sample is scorched after burning, time taken to burn the sample

Controlled variables: The washing procedure (same temperature of 55 degrees Celsius, same time for washing, same time for drying, same detergent for all washes), all samples were burned at the right bottom corner until they caught flame

Procedure

Procedure :

- Remove the shirt from one PJ and label it with 0 washes.

- Hand-wash all fabric with soap and warm water

- Measure out one load of laundry soap

- Add water to the bucket using bath, boiled and kettle water until temperature hits 55 degrees Celsius

- Add soap to bucket and let stand for one minute

- Add all clothing to the bucket and let stand for 10 minutes

- Use tongs to make sure clothing is fully in the water

- Transfer soapy clothes using tongs to another bucket with hot tap water filled up to rinse off soap. Swirl it around with tongs (2 minutes of rinsing)

- Rinse one more time under running hot water and set aside to cool.

- Wait for clothing to cool down and wring out the clothing to remove as much excess water as possible

- Dry in dryer for 40 minutes under timed settings and high heat

- Hang until fully dry

- Repeat washes at another time using the same procedure until all clothing has been washed the number of times needed

- Take pictures and record observations

- Cut fabric into 10 smaller portions for each group using a stencil roughly same size

- Put them on a hanger above a bowl of water (for safety) and light each on fire until it burns. Recorded the start and stop time for each.

- Repeat steps 10-11 for 5 pieces of fabric in each group (0, 1, 5, 10 and 20 washes)

- Put the other 5 aside in case you need extra

- Calculate how long each piece burned

- Calculate the mean of each group ( may have to remove outliers)

- To calculate the scorch area, trace each burned piece and turn the scorch into a triangle

- Record the dimensions of the scorch

- Calculate the area of scorch (estimate using estimated dimensions)

- Calculate how much fabric is left not including scorch

- Repeat steps 16-19 for all 5 pieces of fabric in each group

Observations

- We had to test different sizes of fabric before finding the right one for burning.

- There were a few outliers that we accidentally burned more than others.

- It seemed if the fabric was washed more, it burns more

- A few signs that show chemical change are difference in colour, difference in smell and difference in temperature

Table 1: Table recording the time taken to start and top burning on the fabric with 0 washes

*Did not catch on fire well and had to redo it. So more burned than what we expected

|

0 washes |

Time taken to start burning |

Time taken to stop burning |

Burn time (seconds) |

|

Trial 1 |

00:02.65 |

00:14.60 |

00:11.95 (outlier) |

|

Trial 2 |

00:01.95 |

00:23.65 |

00:21.07 (outlier *) |

|

Trial 3 |

00:02.71 |

00:06.06 |

00:03.35 |

|

Trial 4 |

00:01.90 |

00:04.38 |

00:02.48 |

|

Trial 5 |

00:01:66 |

00:03.96 |

00:02.30 |

|

Mean burn time (seconds) |

8.23 average (including outliers) 2.71 average (removing outliers) |

||

Table 2: Table recording the time taken to start and top burning on the fabric with 1 wash

|

1 wash |

Time taken to start burning |

Time taken to stop burning |

Burn time (seconds) |

|

Trial 1 |

00:03.06 |

00:04.72 |

00:01.66 |

|

Trial 2 |

00:8.13 |

00:08.52 |

00:00.39 (outlier) |

|

Trial 3 |

00:02.16 |

00:04.25 |

00:02.09 |

|

Trial 4 |

00:02.15 |

00:03.38 |

00:01.23 |

|

Trial 5 |

00:01.90 |

00:03.93 |

00:02.03 |

|

Mean burn time (seconds) |

1.48 average (with outliers) 1.75 average (removing outliers) |

||

Table 3: Table recording the time taken to start and top burning on the fabric with 5 washes

|

5 washes |

Time taken to start burning |

Time taken to stop burning |

Burn time (seconds) |

|

Trial 1 |

00:02.06 |

00:03.18 |

00.01.12 |

|

Trial 2 |

00:01.91 |

00:04.70 |

00.02.79 |

|

Trial 3 |

00:02.25 |

00:03.56 |

00.01.31 |

|

Trial 4 |

00:01.56 |

00:02.53 |

00.00.97 |

|

Trial 5 |

00:03.50 |

00:09.52 |

00.06.02 (outlier) |

|

Mean burn time (seconds) |

2.44 average (with outliers) 1.55 average (removing outliers) |

||

Table 4: Table recording the time taken to start and top burning on the fabric with 10 washes

|

10 washes |

Time taken to start burning |

Time taken to stop burning |

Burn time (seconds) |

|

Trial 1 |

00:06.33 |

00:07.71 |

00.01.38 |

|

Trial 2 |

00:02.75 |

00:05.26 |

00.02.15 |

|

Trial 3 |

00:06.41 |

00:06.81 |

00.00.40 |

|

Trial 4 |

00:01.21 |

00:04.51 |

00.02.94 |

|

Trial 5 |

00:05.60 |

00:06.21 |

00.00.61 |

|

Mean burn time (seconds) |

1.50 average |

||

Table 5: Table recording the time taken to start and top burning on the fabric with 20 washes

|

20 washes |

Time taken to start burning |

Time taken to stop burning |

Burn time (seconds) |

|

Trial 1 |

00:05.36 |

00:09.81 |

00.04.45 |

|

Trial 2 |

00:06.30 |

00:7.77 |

00.01.47 |

|

Trial 3 |

00:04.15 |

00:5.63 |

00.01.48 |

|

Trial 4 |

00:06.41 |

00:06.88 |

00.00.47 |

|

Trial 5 |

00:03.05 |

00:21.67 |

00.18.62 (outlier) |

|

Mean burn time (seconds) |

5.30 average (with outliers) 1.97 average (removing outliers) |

||

Table 6: Approximate scorch area of fabrics using triangles with average scorch area for each wash

|

Approx Scorch Area Using Triangles |

0 wash |

1 wash |

5 wash |

10 wash |

20 wash |

|

Control |

0 cm2 |

0 cm2 |

0 cm2 |

0 cm2 |

0 cm2 |

|

Tral 1 |

13.75 cm2 |

4.8 cm2 |

8.2 cm2 |

30.195 cm2 |

21.8 cm2 |

|

Trial 2 |

96.875 cm2 Outlier |

11.05 cm2 |

6 cm2 |

9.9 cm2 |

9.5 cm2 |

|

Trial 3 |

4.56 cm2 |

16.2 cm2 |

5.5 cm2 |

8.845 cm2 |

4.2 cm2 |

|

Trial 4 |

17.235 cm2 |

5.95 cm2 |

4.875 cm2 |

7.215 cm2 |

9.5 cm2 |

|

Trial 5 |

3.74 cm2 |

10.725 cm2 |

6.48 cm2 |

4.48 cm2 |

22.525 cm2 |

|

Average scorch area |

27.232 cm2 (with outlier) 9.82 cm2 (without outlier) |

9.745 cm2 |

6.211 cm2 |

12.127 cm2 |

13.505 cm2 |

Table 7: Approximate area of fabric left over after burning with average area of fabric leftover for each wash

|

Approx Area of Fabric Left over |

0 wash |

1 wash |

5 wash |

10 wash |

20 wash |

|

Control |

355.81 cm2 |

355.81 cm2 |

355.81 cm2 |

355.81 cm2 |

355.81 cm2 |

|

Tral 1 |

348.935 cm2 |

351.01 cm2 |

347.61 cm2 |

325.615 cm2 |

334.01 cm2 |

|

Trial 2 |

258.935 cm2 |

344.76 cm2 |

349.81 cm2 |

345.91 cm2 |

346.31 cm2 |

|

Trial 3 |

351.25 cm2 |

339.61 cm2 |

350.31 cm2 |

346.965 cm2 |

351.61 cm2 |

|

Trial 4 |

338.485 cm2 |

349.86 cm2 |

351.025 cm2 |

348.595 cm2 |

346.31 cm2 |

|

Trial 5 |

352.07 cm2 |

345.085 cm2 |

349.33 cm2 |

351.33 cm2 |

333.285 cm2 |

|

Average area of fabric leftover |

329.935 cm2 |

346.065 cm2 |

349.617 cm2 |

343.683 cm2 |

342.305 cm2 |

Analysis

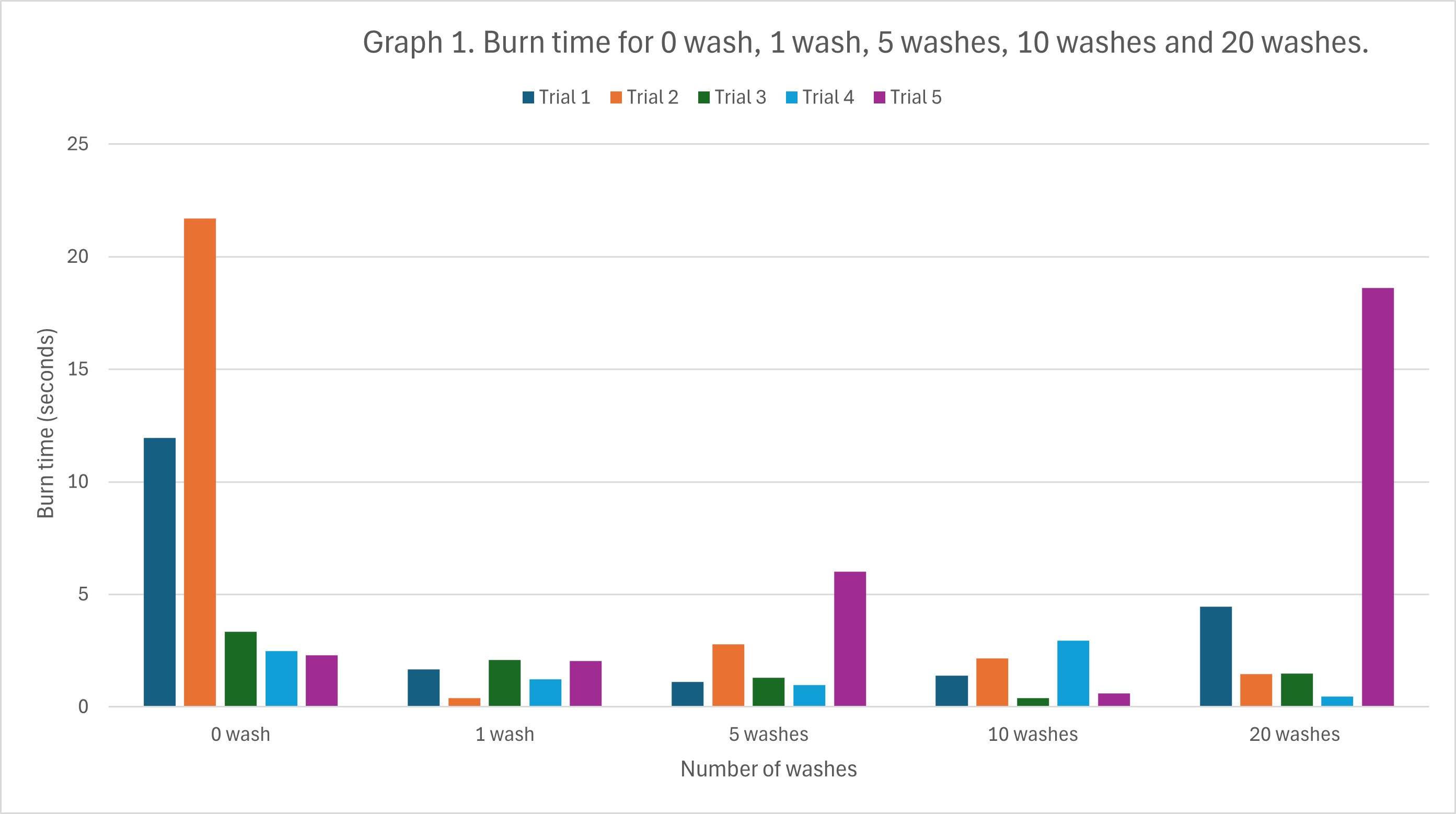

- The trend increases and decreases

- The 5 wash (trial 5) had the highest burn time (without outliers)

- The 10 wash (trial 3) had the lowest burn time

- Outliers: I notice that 0 wash (trial 2 and 1) and 20 wash (trial 5) are outliers because the burn time is too high compared to the other values

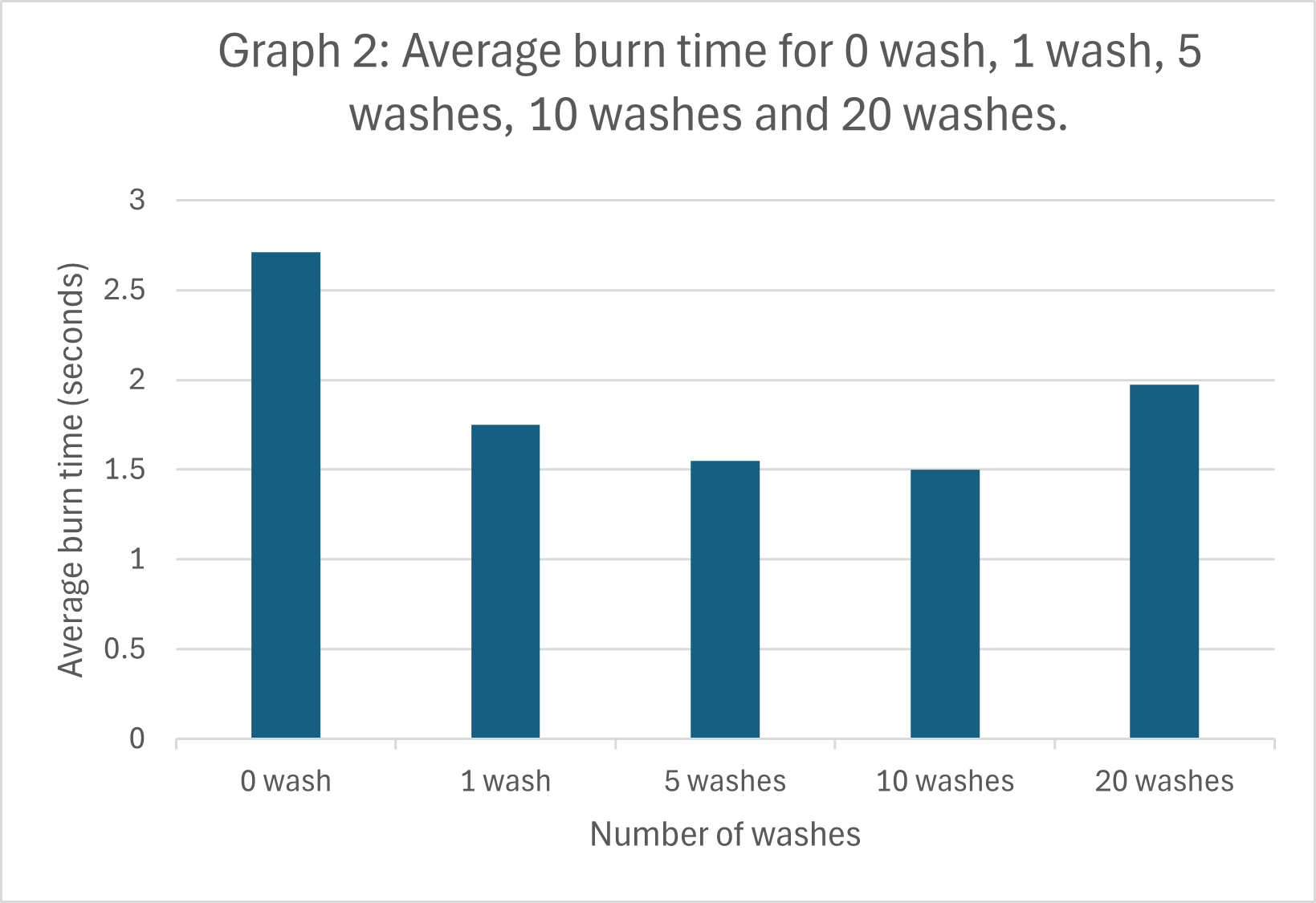

- The trend for average burn time increases and decreases.

- 0 wash had the highest burn time

- 10 wash had the lowest burn time

- I notice that if you look at the bars you see a stretched out U shape because the bars go high-low- high just like the letter ‘U’.

- The trend increases and decreases, but mostly increases.

- Biggest scorch area was 10 wash (trial 1) (without outlier)

- 20 wash (trial 3) had the lowest scorch area

- The 0 wash (trial 2) sticks out because it is so huge

- The general pattern was lowest to highest but 5 washes does not fit the pattern.

- General pattern: As the number of washes increases, the mean scorch area tends to rise as well

- 20 washes had the highest mean scorch area

- The lowest mean scorch area was 5 washes

- Bar for 5 washes looks like it doesn't fit because it’s too small

Conclusion

When looking at all the trials, the highest scorch area was for the 10 wash fabric (trial 1). In the average scorch area (graph 4) the 20 washes fabric had the highest scorch area because it had the most fire resistant chemicals washed off.

The common flame retardant chemicals are called Organophosphate flame retardants (OPFR) and perfluoroalkyl substances (PFAS). These chemicals have both hydrophobic and hydrophilic structures. Hydrophobic substances are substances that do not mix well with water. Hydrophilic substances that mix well with water.

The OFPRs and PFAs are chemicals that have hydrophilic structures which means that it will mix easier with water. This explains the results of my experiment because the water dissolves the flame resistant chemicals in the PJs. Since the flame resistant chemicals mix with water and come off the pajamas, it would burn more because the chemicals stop the fire and that is what is getting dissolved and washes away in water.

Sodium hydroxide is the main ingredient in the laundry detergent and is also a base. The organophosphates (the flame resistant chemicals) are acids because they have phosphate groups which are acidic. When acids and bases mix they form a new neutral substance through a neutralization reaction which means it is not an acid or a base. When organophosphates and the laundry soap react it neutralizes the organophosphates and the structure of the chemicals change. If the chemical structure of the organophosphates changes, the clothes will burn more when they are washed with soap.

This explains why the 20 wash had the most burn area on average. When we washed the pajamas more, the water mixed with the chemicals and washed it away. When we wash the pajamas with more soap, it combines with the fire resistant chemicals and makes it neutral. The 20 wash fabric now has a smaller amount of fire protective chemicals causing the pjs to burn more.

Application

I learned that the 20 wash fabric burned more because I washed it more (Graph 3). This affects people wearing flame resistant clothes because they might wash it more and it will become less fire resistant. This is a safety hazard.

Research says that flame retardants like OFPRS and PFAs are not chemically bound to the PJs. They can flush into the external environment and people could consume these chemicals through dust or through hand to mouth contact. This is a problem because we could consume these chemicals and it could be a health hazard.

The flame retardants are a health hazard because trained professionals worry that flame retardants have chemicals that can lead to cancer, neurotoxicity and hormone disruption (hormones are disrupted from doing their task). In 1972, for five years, rules were in place that required children’s Pajamas to be flame resistant. They used Brominated tris but then it was replaced with chlorinated tris, because children were exposed to carcinogens in their sleep through exposure in the skin. Chlorinated tris was also bad because it was found to affect DNA. People may be exposed directly to the flame retardants by the chemicals directly on their clothes.

The chemicals are an environmental hazard because laundry water washes off flame retardants and it can go into the lakes and rivers and affect animals and fish in the water. In a study from South Korea, scientists found out that it had a high concentration of flame retardant ant chemicals

Sources Of Error

- During the washes some pajamas may have had excess soap than others. This might affect the results because there could be more chemicals reacting in one pair than in another and make it an unfair experiment. We could have changed our washing procedure to remove this error by using a washing machine. In the washing and drying machine every fabric gets an equal amount of soap.

- It was difficult to use our stencil to cut the pajamas into equal pieces. Sometimes we may have stretched the fabric more than others when we were cutting. This might affect the results because there could be an uneven area of fabric and we will have wrong measurements for the scorch area. We could have resolved this by using a ruler to measure and a marker to mark how we are going to cut the fabric. We label the dimensions then cut along the guidelines.

- It was difficult to burn them evenly because the fabric was crinkling up at the corner and it was hard to see if there was a flame already started or not. This is a source of error because we may have recorded the time wrong. We could have stopped this by holding and keeping the fabric straight by using an object such as a clothespin.

- It was also difficult to watch the time and watch the flame at the same time and be accurate with the timer. We know this happened because there were outliers in the data. We might be able to reduce this by having a third person - 1 for the timer, 1 to light the flame, and 1 to record when it started and when it stopped burning.

- We cannot time it exactly because it might be 5-10 milliseconds late. This is a source of error because we might have the wrong burn time measurements. We could fix this by having multiple trials so if 1 fails we have more and we could use the most accurate ones.

Citations

https://cen.acs.org/articles/92/web/2014/09/Fire-Retardants-Wash- .html

https://greenathome.ca/flame-retardants-childrens-pajamas/

https://learn.eartheasy.com/articles/flame-retardants-how-to-drastically-reduce-your-e

https://www.canada.ca/en/health-canada/services/safe-sleep/children-sleepwear.html

https://laws-lois.justice.gc. Aww Aww ca/eng/regulations/SOR-2016-169/page-1.html#h-831495

Fateeha - Student in first year University (tutor)

Blessy Mathew - Elementary/Junior High Teacher (tutor)

Reneeta Lakhani - Math Teacher (mom)

Acknowledgement

I want to thank Raheel Lakhani (dad) for helping bring up hot water and wringing out excess water from pyjamas before they went into the dryer.

I want to thank Reneeta Lakhani (mom) for lighting all my pajama samples on fire because it was too dangerous for me.

I want to thank Blessy and Fateeha (tutors) for allowing me to ask them questions and helping me understand areas of my project.

I want to thank Mrs. Ghosh and Mrs. Riel for being teacher supports at my school during the science fair. They provided me with all the steps needed to be successful throughout my project.

I want to thank Mr. Nielsen for teaching me about how to calculate mean because I used it in my project.