Trash to Gas - Biogas Energy

Grade 7

Presentation

Hypothesis

If we add a carbohydrate rich waste to manure, then it will yield more biogas when compared to manure alone or manure mixed with a low carbohydrate organic waste. This is because carbohydrates degrade more easily when compared to proteins and thus help with digestion and biogas production.

Research

Biogas

Composition and Origin-

Biogas consists primarily of carbon dioxide (CO2) and methane (CH4) with small increments of hydrogen sulphide (H2S), water (H2O), and siloxanes(R3Si(OSiR2)nOSiR3). Siloxanes are a chemical compound with their backbone being oxygen and silicon. They are used in a variety of products, including many creams and deodorants. They make a substance smoother. Biogas is produced through the process of anerobic digestion, which is the decomposition of organic waste in the absence of oxygen. We can derive biogas from a variety of sources of organic waste, such as food waste, sewage sludge, animal manure, and other organics. The anerobic digestion process has 4 stages, them being, hydrolysis, acidogenesis, acetogenesis, and methanogenesis. The production of biogas is also a cyclic process and may be repeated multiple times to obtain the same result. For example, if you are a businessman whose industry produces a lot of organic waste, you can make biogas using those discards. The energy harnessed can then be used to power the industry's machinery and facilities.

Digestate-

One of the byproducts of biogas is digestate, the leftover material that can no longer be broken down through the process of anerobic digestion. This is about 90% of the original material and can be used for a variety of purposes, including being used as a natural fertilizer, animal bedding, or as a base for biodegradable products.

Usage and Purification-

Biogas can be used to generate heat, electricity, and power. It can also be used as to run alternative fuel vehicles. We can also purify biogas to produce Renewable Natural Gas (RNG) This is done through removing the trace gases, such as, carbon dioxide and water from the original composition.

Alternative Fuel-

Biogas can also be used as an alternative fuel to other forms of energy that are not as good for the environment. Biogas can be used as a replacement to fossil fuels that increase the chances of smog and acid rain. This occurs due to the burning of fossil fuels produces substances like sulfur dioxide and nitrogen oxides which can react with the oxygen and components in the air. This can then lead to acidic precipitation, or acid rain. This in hand can also lead to low visibility levels due to increased air pollution, or smog. The usage of fossil fuels also contributes to global warming. This occurs when the gases produced by the burning of fossil fuels trap heat inside the earth’s atmosphere, and don’t let it escape. This makes the earth hotter, leading to it getting warmer over time. These gases can also lead to many other negative impacts. Biogas can also replace natural gas as 80% of natural gas in the United States comes from fracking. This requires drilling deep into the earth's crust and can lead to the disruption of landscapes and ecosystems. Biogas usage also reduces the amount of nitrogen pollution and waste runoff into water sources. It can also be made in household, which reinforces the fact that it is a low-cost fuel and is a reliable source of energy in the future.

Biomass

Biomass is a heterogeneous form of waste that may be used in the production of biogas. It comes in 3 main categories which include the following-

Natural-

This biomass is formed throughout nature without any human interference. Some examples include, fallen branches, dried up leaves, and other natural components.

Residual-

This biomass is produced through courtsey to humans and may come from agricultural, livestock, or industrial activities. These can then later be classified as either wet or dry.

Energy Crop Biomass-

This is biomass that comes from crops that are specifically grown to increase the amount of living matter that can be used as energy. Certain crops may be grown to maximize energy production.

Benefits-

There are many benefits to using biomass as a fuel. It is a sustainable, financially friendly, and accessible source of fuel that can be harnessed through the production of organic waste, which is found everywhere. It can reduce our dependence on fossil fuels and create many opportunities in rural areas where there is energy poverty and fossil fuels are an expensive resource to obtain. Biomass is also renewable and supports a circular economy. This biomass can in turn be used to produce biogas, as well as other sources of energy that are based off of it.

This biomass can then be divided further into more categories which inlcude the following-

Food Waste-

Landfill Gases-

These are the gases produced in a landfill when the waste in them decomposes. They are the third largest human connected methane emission sourcce in the Untied States. The landfills contain the same bacteria that is present in the process of anerobic digestion. Therefore, we can then harness this gas to power a variety of things.

Crop Residue-

Crop trimmings may consist of plant trimmings, stalks, and straws. These parts of the produce used to be left on the field post harvest to retain soil organic content and play a role in the reduction of soil erosion, but due to the amount of crops harvested currently, removing them from the field may actually be beneficial. Though the amount of sustainabiltiy may vary depending on the type of soil and climate, as welll as other factors. These can then be co-digested alongside other wastes because their high lignin content makes them hard to break down.

Wastewater Treatment-

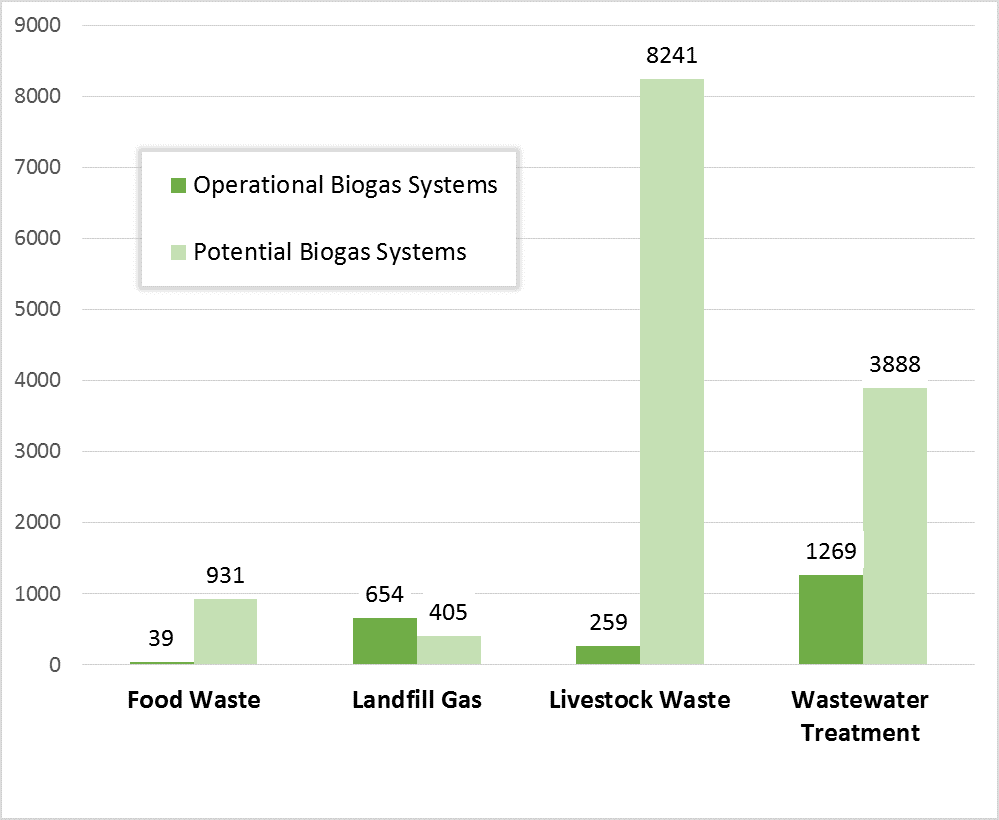

There are many wastewater treatment facilities that have an anerobic digester onsite, but there are not many that have an energy recovery system. Of 1269 facilities with digesters, only 860 of them use the biogas they produce. The ones who do not have the ability to use the gas, they flare it instead,w hcih is hazardous for the environment in a variety of ways. It can lead to excess Co2 emissions, as well as the production of black soot, as well as health hazards. These facilities could have a major positive impact if they are installed with energy recovery resources.

Livestock Waste-

A 1000 pound dairy cow can produce up to 80 pounds of manure a day, which is usually stored in tanks before it is applied to the fields. This manure produces methane as it decomposes and it can contribute to the issue of excess nutrients in waterways. This is an issue because these nutrients can [promote the growth of algae and this can foster an imbalance in the ecosystem. Using this manure to produce biogas has many benefits which include reduced odors and greenhouse gas emissions.

Digesters

There are many ways through which we can describe digesters. They include the following-

Stand Alone-

They accept waste from a number of sources for a tipping fee. This is fee applied to waste given to a processing facility and may be calculated by weight or other factors. Stand alone digesters can be run by a community, municipality, or other organization. Some stand alone digesters at processing facilities in the food and beverage industry are designed to process a certain kind of waste that the industry produces. These digesters generally do not accept waste from other sources. Stand alone digesters are primarily made to process food waste, but can co-digest other things along with that, such as yard waste, and manure. They are becoming more common as much of organic waste is being taken away from landfills.

On Farm-

These digesters can assist farmers in managing nutrients and acquiring other benefits. These include reduction of odors, and additional revenue. These digesters may also take in food waste from sources other than the farm as a feedstock. The energy harnessed through them can be used to generate heat, electricity, and power.

Water Resource Recovery Facilities-

These digesters can produce freshwater, recover nutrients, and reduce our reliance on fossil fuels, which are extremely harmful for the environment. They can vary in various aspects, including size, shape, and digesting technique.

Wet/Dry Solids-

These digesters digest waste based on the amount of moisture content in the waste. Wet digesters are more common when compared to dry digesters, and are mainly used to digest waste with less than 15% of a solid content. The waste is typically in a slurry form and is pumped. Dry digester process waste with more than 15% solid content and the waste they process is considered stackable.

Feedstock Variation-

This is when a digesters may only be programmed to digest a specific kind of feedstock while another one could be compatible to a variety. Many different wastes benefit form predigesting techniques, which include screening, blending, and thermal conditioning.

Operating Temperature-

These digester run at specific temperatures because different kinds of anerobic microbes thrive in their respective environment. 86-100 F is for mesophilic and 122-140 F for thermophilic. Thermophilic anerobic digestion accelerates the biogas production and kills pathogens present in the waste. It can handle more waste, though it requires more energy and heat for maintenance.The biogas they produce contains more methane nad the digestate is also safer to use for its many purposes. In the midst of all the benefits though, thermophilic anaerobic digestion is less steady and things can go wrong faster than they will in mesophilic digestion. Mesophilic digestion can occur in a cooler environment, though it will produce the biogas at a slower rate when compared to thermophilic anerobic digestion.

Batch and Continuous Flow-

Batch is when all the waste is loaded onto a digester for a fixed amount of time and is taken out later, while continuous flow is when the waste is constantly loaded on and emptied.

The Anerobic Digestion Process

The process of anerobic digestion consists of 4 steps, each of which have their own role in the creation of biogas. They include the following respectively-

Hydrolysis- In this part of the anerobic digestion process, specific bacteria decompose organic polymers, such as carbohydrates, into simpler sugars sot the next stage of bacteria can further process them.

Acidogenesis- In this stage of the process, acidogenic bacteria break down these simple sugars and amino acids into other substances. These include carbon dioxide, ammonia, organic acids, and hydrogen.

Acetogenesis- In this stage pf the process, acetogenic bacteria break down the organic acids into carbon dioxide, hydrogen, and acetic acids.

Methanogenesis- This is the final stage in the process and it is when single-celled organisms known as methanogens converts the previously broken down material into biogas.

After all of these different stages in the anerobic digestion process, digestate is produced.

Food Waste

Food waste and food loss are two different things as food loss is food being lost or going uneaten along the process of the food chain, while food waste is more of a specific kind of food loss. It refers to food discards by businesses due to its color or appearance, or food discarded by consumers.

Food loss is a global issue that leaves a lasting negative impact on our planet and it occurs in a variety of places that include the following-

Farms

There are many reasons through which food may be lost on farms. Many times farmers will plant more crops in preparation for the occurrence of negative weather and pests. This production of more than the demand can lead to edible food being thrown away. Farmers may also not harvest food that has been damaged by pests, the weather, and disease. They may also leave crops unharvested if the market value of the them at the time is lower than the costs it took the farmer to produce that food through transportation and storage. One of the other factors playing a role in the creation of food waste on farms is produce with imperfections at the surface. many consumers may not be interested in such food, and this hence leads to it being thrown away. Improper refrigeration and handling of food on farms can also lead to it finding a place in our landfills. hough the government has organizations to deal with excess food, the system through which it works is difficult and expensive.

Manufacturing and Processing Facilities-

One of the reasons for food waste at manufacturing and processing facilities is the trimming and removal of edible portions of the original food. These portions can include, fats, crusts, and skins. Though about 33% of these trimmings are taken into animal feed, the ones that do not still leave a lasting negative impact. Other problems that may occur at these facilities include overproduction, technical issues, and product damage, all of which can lead to food being lost. Another factor playing a role in this is that these facilities are subject to labour shortages. An example of such a situation was observed during the Covid-19 pandemic when many of workers fell ill and the animals that were being processed had to be thrown away.

Distribution Networks-

Much of the perishable food products are lost in this part of the process as in countries that do not have enough resources to store and transport food in such a way there is minimal waste. These products have an expiry date, and they have to be thrown out if not eaten before the specified time.Though this is not observed in other countries with resources, but many spills occur due to improper refrigeration . Another reason is that many of the perishable food products have to be thrown out if no one is willing to purchase them, or they get rejected. It is estimated that 2-5% of food shipments get rejected by buyers, which can lead to a significant amount of food loss.

Food waste also has many problems associated with it and it occurs in the following places-

Retail Businesses-

It is estimated that 43 billion pounds of food were wasted in the US in 2010. Much of the food which is lost is perishable and the wastage of it can arise from a variety of issues. These may include overstocking, damaged products, cosmetic perfection in products for consumers, expired "sell by" dates, understaffing, as well as over purchasing of unpopular goods. It is unfortunate that these wasteful practices are considered good business strategies in the corporate world. It is estimated that supermarkets in the U.S. lost $15 billion just through the wastage of fruits and vegetables alone.

Households-

Households contribute to a significant amount of organic food waste around the world though mostly either misunderstanding or lack of awareness. One of the factors that can lead to food wast in households is that many American misunderstand labels on packaged food, such as seel by or best by labels. These labels are not regulated by the government and are just an estimate for peak quality. Spreading awareness about not misconceiving these labels can reduce food waste by 20%, as the UK suggests. Another factor is that many household overprepare and have large serving portions, which can lead to leftovers which are thrown away if not eaten soon enough. Serving portions in cookbooks and other publications have also increased, which can contribute to food being wasted in this manner. Another aspect of food being wasted in households is food spoilage, which can happen through poor planning or misjudgment of the amount of food needed through a certain period of time. Other similar factors include overubying, and poor planning, both of which can lead to food being wasted.

Restaurants and Institutions-

Restaurants in the U.S. waste an estimated 22-33 billion pounds of food each year, with hospitals and schools depositing their own 7-11 billion pounds. These large amounts of wasted food can be produced through a variety of issues which include extensive menu options in restaurants and an inflexibility in chain store management. Another larger aspect is that serving portions have increased largely over time and they are about 2-8 times larger at most places than the USDA recommends. More issues that contribute include poor storage of materials, as well as the loss of leftovers. Buffets specifically waste more since most businesses want to keep the trays full stocked during open hours, and this food cannot be legally donated due to health safety. If the food is not finished, then it is thrown away.

Environmental Impact-

One of the factors in this issue is that food waste contributes to solid waste, which is a problem in itself. An organization in the UK known as WRAP suggests that removing food from landfills will be equivalent to taking 1/5 of the cars off the road in the UK. More aspects include is freshwater pollution and energy wastage. The production of food requires a lot of energy and freshwater and throwing away the food is like losing the resources that it took to produce it.

Variables

Manipulated Variables-

- Cow Manure

- Cow Manure + Vegetable Peels

- Cow Manure + Mashed Bananas

Controlled Variables-

- Outside Temperature

- Size of botttles

- Intial water level

- Bottle shaking/tilting

- Amount of organic waste contained in each bottle

Responding Variable-

- The amount of biogas produced through the different combinations of waste.

Procedure

Experimental Procedure

- Take out the 9 1 litre bottles, clean and dry.

- Using a permanent marker and transparent tape, label 3 of the bottles Cow Manure.

- Label another 3 bottles Cow Manure + Vegetable Peels

- Label the last 3 of the bottles as Cow Manure + Mashed Bananas

- Put on a pair of disposable gloves.

- Using a small paper cup and kitchen scale, measure out 60g of cow manure.

- Scoop the manure with your disposable gloves into one of the bottles labelled Cow Manure.

- Repeat steps 6 and 7 until all 3 bottles labelled Cow Manure have 60g of manure in them.

- Tare the scale and using a fresh paper cup, measure out 30g of vegetable peelings. (Consider the size, as smaller pieces of peelings decompose easier) Scoop them into one of the bottles labelled as Cow Manure + Vegetable Peels.

- Tare the scale and measure out 30 g of cow manure into another cup. Scoop it into the same bottle labelled Cow Manure + Vegetable Peels

- Repeat steps 9 and 10, until all 3 bottles labelled Cow Manure + Vegetable Peels have 30g of peelings and 30g of manure in them.

- Tare the scale and using a fresh paper cup, measure out 30g of mashed bananas. Scoop them into one of the bottles labelled as Cow Manure + Mashed Bananas.

- Tare the scale and measure out 30 g of cow manure into another cup. Scoop it into the same bottle labelled Cow Manure + Mashed Bananas.

- Repeat steps 12 and 13, until all 3 bottles labelled Cow Manure + Mashed Bananas have 30g of mashed bananas and 30g of manure in them.

- Using a ruler, make a mark 4 cm from the mouth of all the bottles.

- Fill distilled water into all the bottles until that mark.

- Acquire the 9 balloons and check them for any holes or any other forms of leakages.

- Fasten 1 balloon onto the mouth of every bottle and secure it with a few rounds of shipping or packing tape. The bottles should be sealed completely to avoid any gas leakage.

- Place all the bottles in a well ventilated area and observe them daily.

Factors of Consideration

- The bottles should be placed in a relatively warm place to increase the biogas yield as much as possible.

- Tilt the bottles regularly to dislodge any biomass accumulation near the top. Make sure no water or biomass gets into the balloon when doing so.

Observations

There were quite a few things that I observed over the course of conducting this experiment. One of the most noticeable was the accumulation of biomass a few centimetres below the mouth of the bottles. The most accumulation occurred in the first few days of the experiment in the mashed banana and vegetable peel bottles, but not so much in the bottles with just plain manure in them. Those ones only had a few small bits of manure floating at the top. These accumulations in the bottles could possibly have created a clog and not let the gas get through, so I tilted and shook the bottles occasionally to dislodge the biomass and move it to the bottom of the bottle. I also noticed that when I shook the bottles, only a portion of the biomass dislodged, but it then floated back to the top. Though this occurred, the shaking of the bottles did adjust some of the biogas into the balloons, and therefore a small amount of inflation occurred. Another thing that I observed was the formation of bubbles near the mouths of the bottles that did produce biogas. Since these bubbles were only produced in the bottles that did produce biogas, I would like to infer that the formation of bubbles is a sign of biogas production. Bubbles are also filled with gas, and this proves the previous statement. There was also one queer occurrence that happened only in the plain manure bottles, and this was the vacuum. It started of as just a small dip in the stretched part of the balloon, but over the course of the next few days, the vacuum became really deep and sucked in more than half the balloon with it. Thirdly, I observed that water levels had decreased in the bottles as time passed. Many balloons that inflated previously also deflated over the other days. This may have been due to many factors and was one of the sources of error in my experiment. The final thing that I observed was that the mashed banana + cow manure bottles produced the most biogas and the vegetable peels + cow manure produced the second most. I did not see any visible gas production in the plain cow manure bottles. Those were some of the things that I observed over the course of my experiment and they played a role in the production of biogas.*

*I was not able to upload some of my photos directly to this platform, but I have added a file from them in my additional attachments section.

Analysis

The results of my experiment may also be analyzed through a variety of points. One of them was the fact that bananas are a carbohydrate rich fruit. This assist us in the production biogas as carbohydrates are a easily decomposable component compared to others. The quicker degradation is what produces more biogas, as anaerobic digestion relies on bacteria breaking down organic material in the absence of oxygen. Another aspect through which we can analyze my experiment is that my experiment was working through mesophilic anaerobic digestion, which is a slower and more temperate process when compared to thermophilic digestion, which can produce biogas faster but needs higher temperatures to do so. This is important because my makeshift digesters took at least a day or two to show any visible gas production, and this may have been due to the not so high temperatures, making the digesting process work at a less faster rate than it most probably would have in an environment with much higher temperatures.

Conclusion

There was one major takeaway from the conduction of this experiment, and it was that mashed bananas produced the most biogas when co-digested alongside cow manure. In a broader sense, my experiment proves that co-digestion of biomass and feedstocks is a far more efficient way of digestion than single material digestion. We observed that only a vacuum was formed in the Cow Manure bottles and no gas production was observed and the vegetable peel bottles produced gas also, but not as much as the mashed banana bottles. That is why the mashed banana bottles, vegetable peel bottles, and cow manure bottle produced the most biogas respectively. Thus we can come to the conclusion that co-digestion is a better way of digesting biomass than single material digestion, as well as that carbohydrate content is an important consideration when looking for biomass that can produce the most biogas.

Application

There are many ways through which the concept of biogas can be applied to the real world.

One of the primary ways is that biogas is clean source of energy and it can be a reasonable alternative to fossil fuels and natural gas, both of which are bad for the environment and they contribute to pollution, as well as unstable ecosystems. 80% of natural gas in the Untied States comes from the process of fracking, which requires mining deep into the earths crust to extract the substances that make up natural gas. This form of acquiring energy can disrupt ecosystems and landscapes. Fossil fuels contribute to smog, acid rain, and global warming. Global warming is constantly heating up the planet through greenhouse gases which trap heat from the sun in the earth's atmosphere, in turn making the earth hotter. Biogas may also be purified into RNG, which is produced by removing trace gases from the composition of gases that make up the biogas. This is why biogas may be used as a more common alternative fuel in the future.

Another way through which biogas can be applied to the real world is that it is a low cost fuel and it can open up many opportunities in rural areas around the world where affording industrial fuels can be expensive. There are all methods through which people at home can make and use their own biogas. This will help many households utilize their organic waste for their own benefit. The energy produced can be used to power a variety of appliances around the house and it can benefit the environment as a result. This reinforces the fact that biogas is a low cost fuel and it can be made anywhere.

The production of biogas is also a cyclic process and it is a renewable source of energy. Biogas is harnessed through the process of anerobic digestion, which requires breaking down organic waste in the absence of oxygen. There are many factories and manufacturing facilities around the world that produce a colossal amount of biomass (organic waste) each year. The factories can then use this waste to produce biogas and run their factory for the next year. This may reduce emissions and help many businesses turn to environmentally friendly practices.

Anaerobic digestion also produces a material known as digestate, which can then be used as fertiliser, bedding for livestock, and as base for environmentally-friendly products. This can be a substitute to artificial fertilizers which are harmful to the environment as they pollute waterways and they contain many chemicals which can deteriorate soil health through harming many organisms and microbes that play a major role in the growing of a plant.

My experiment explored which combinations of waste can possibly create the most biogas. My results of carbohydrate rich fuels producing the most biogas may assit many farmers, as well as other indivduals or or organizations who work to proudce the most amount of biogas possible.

Those were some of the ways throough which biogas may be applied to the real world and make it a better place for everyone.

Next Steps

There are many ways through which I can improve this project in the future, including the following-

The first thing is that I could have a better measuring system whcih could help me in obtaining precise measurements which can expand the horizons of my project through the process of paying attention to detail. Simiar to better measuring sysytem, I could also have better digester technology which could enhace the biogas production even further, giving me more accurate results for my experiment.

I also could test a higher number of combinations of waste to see how different hutrients break down and how they contribute to biogas production.

Sources Of Error

There were a few factors that may or may not have affected my resukts in this experiment-

- One of the factors was the balloon quality. They may have allowed some gas seepage and may have not given the most accurate results, but they did do pretty well primarily.

- Another aspect was that though my house is on a thermostat, there may have been some temperature changes throughout the course of the experiment. I also had to move the bottles 3 times from one place to another, and the room size may have affected the temperature

- The final source of error was least likely, but when I was tilting the bottles, some amount of water may have entered the balloon. This could have affected my results, but I seriously doubt its occurence. I also may not have tilted all the bottles to the same degree as I tilted others, so that may have laso had an imapct on my results.

Citations

5 facts about food waste and hunger: World Food Programme. UN World Food Programme. (n.d.). https://www.wfp.org/stories/5-facts-about-food-waste-and-hunger

Alexina Cather, M. (2021, March 16). Down the rabbit hole: Why measuring food waste is so confusing. NYC Food Policy Center (Hunter College). https://www.nycfoodpolicy.org/rabbit-hole-measuring-food-waste-confusing/

Anaerobic digestion. Tennessee State Government - TN.gov. (n.d.). https://www.tn.gov/environment/program-areas/sw-mm-organics/anaerobic-digestion.html#:~:text=Hydrolysis - the first step in,can further process the material.

Arjan. (2025, January 7). What is the difference between natural gas and biogas?. Membrane Systems Europe B.V. https://biogasmembrane.com/news/what-is-the-difference-between-natural-gas-and-biogas/#:~:text=Natural%20gas%20sounds%20like%20it’s,a%20renewable%20source%20of%20energy.

Author links open overlay panelJuan Camilo Solarte-Toro, & AbstractThe use of nonrenewable energy sources to provide the worldwide energy needs has caused different problems such as global warming. (2018, April 3). Evaluation of biogas and syngas as energy vectors for heat and power generation using lignocellulosic biomass as raw material. Electronic Journal of Biotechnology. https://www.sciencedirect.com/science/article/pii/S0717345818300101#:~:text=Moreover%2C%20the%20investment%20costs%20to,heat%20and%20power%20than%20syngas.

Benefits of biogas. American Biogas Council. (2024, October 7). https://americanbiogascouncil.org/resources/why-biogas/#:~:text=Biogas%20systems%20protect%20our%20air,food%2C%20water%20and%20animal%20waste

Biomethane. Energy. (n.d.). https://energy.ec.europa.eu/topics/renewable-energy/bioenergy/biomethane_en#:~:text=Biomethane%20is%20the%20purified%20version,Key%20actions%20on%20biomethane

Biopower basics. Energy.gov. (n.d.-a). https://www.energy.gov/eere/bioenergy/biopower-basics#:~:text=Most%20electricity%20generated%20from%20biomass,drives%20a%20generator%2C%20producing%20electricity

Biopower basics. Energy.gov. (n.d.-b). https://www.energy.gov/eere/bioenergy/biopower-basics#:~:text=Most%20electricity%20generated%20from%20biomass,drives%20a%20generator%2C%20producing%20electricity.

Canada, N. R. (2025, January 7). Government of Canada. Natural Resources Canada. https://natural-resources.canada.ca/our-natural-resources/energy-sources-distribution/renewable-energy/bioenergy-systems/biomass-gas/7401

Create flammable gas with biomass | science project. (n.d.-a). https://www.sciencebuddies.org/science-fair-projects/project-ideas/Energy_p027/energy-power/from-trash-to-gas-biomass-energy

Digestate. Anaerobic Digestion. (n.d.-a). https://www.biogas-info.co.uk/about/digestate/#:~:text=Digestate%20is%20a%20nutrient%2Drich,was%20fed%20into%20the%20digester.

Digestate. Anaerobic Digestion. (n.d.-b). https://www.biogas-info.co.uk/about/digestate/#:~:text=Digestate%20is%20a%20nutrient%2Drich,was%20fed%20into%20the%20digester.

Dumlu, L., Ciggin, A. S., Ručman, S., & Perendeci, N. A. (2021, July 9). Pretreatment, Anaerobic Codigestion, or both? which is more suitable for the enhancement of methane production from agricultural waste?. Molecules (Basel, Switzerland). https://pmc.ncbi.nlm.nih.gov/articles/PMC8303515/#:~:text=Codigestion%20of%20agricultural%20wastes%20with,during%20anaerobic%20digestion%20%5B18%5D

Environmental and Energy Study Institute (EESI). (n.d.). Fact sheet: Biogas: Converting waste to energy. EESI. https://www.eesi.org/papers/view/fact-sheet-biogasconverting-waste-to-energy

Environmental Protection Agency. (n.d.-a). EPA. https://www.epa.gov/anaerobic-digestion/types-anaerobic-digesters

Environmental Protection Agency. (n.d.-b). EPA. https://www.epa.gov/agstar/how-does-anaerobic-digestion-work

Environmental Protection Agency. (n.d.-c). EPA. https://www.epa.gov/anaerobic-digestion/basic-information-about-anaerobic-digestion

EPA. (n.d.-b). https://www.epa.gov/sites/default/files/2014-12/documents/codigestion.pdf

Farm-Energy. (2019, April 12). Uses of solids and by-products of anaerobic digestion. Farm Energy. https://farm-energy.extension.org/uses-of-solids-and-by-products-of-anaerobic-digestion/#:~:text=Digestate%20solids%20can%20also%20be,content%20reduce%20the%20energy%20potential.

Frequently asked questions (biogas FAQ). Biogas. (n.d.). https://biogas.ifas.ufl.edu/FAQ.asp#:~:text=While combustion of biogas, like,add to greenhouse gas emissions.

J., M. (2023, September 27). What are siloxanes: Chemical free living. Force of Nature. https://www.forceofnatureclean.com/chemical-free-living-what-are-siloxanes/

Margo. (2024a, March 12). The biogas production process explained. HomeBiogas. https://www.homebiogas.com/blog/the-biogas-production-process-explained/?srsltid=AfmBOoo4TB5TRgUN0RYEFz27HAIcKdV9GbLKS4as3OQxaJmDRQLnBfMX

Margo. (2024b, March 12). The biogas production process explained. HomeBiogas. https://www.homebiogas.com/blog/the-biogas-production-process-explained/?srsltid=AfmBOoo4TB5TRgUN0RYEFz27HAIcKdV9GbLKS4as3OQxaJmDRQLnBfMX+++https%3A%2F%2Fwww.epa.gov%2Fanaerobic-digestion%2Ftypes-anaerobic-digesters

Margo. (2024c, October 13). How to make biogas at home – a step-by-step guide. HomeBiogas. https://www.homebiogas.com/blog/how-to-make-biogas-at-home/

The problem of food waste. FoodPrint. (2024, December 11). https://foodprint.org/issues/the-problem-of-food-waste/

Sekhar, - Metla Sudha, Mukeri, - Zafer, Elearnmarkets, De, - Tanusree, Rai, - Sachenkumar, Agrawal, - CA Raj K, Patni, - Prince, Vskills, Somani, - Shraddha, Gupta, - CA Rahul, Haque, - Ameen, & Aaker, - Dr. David. (n.d.). How biogas can reduce India’s dependency on fossil fuels and lower energy costs? The Economic Times. https://economictimes.indiatimes.com/industry/renewables/how-biogas-can-reduce-indias-dependency-on-fossil-fuels-and-lower-energy-costs/articleshow/113415904.cms?from=mdr

Shapiroe.com. (2024, May 20). Biogas: Definition, uses, Types & Sources. Shapiro. https://shapiroe.com/blog/biogas-generation-guide/

Siese, M. (2024, January 30). Anaerobic digestion vs gasification: Navigating the future of energy technologies. Acorn Bioenergy. https://www.acornbioenergy.com/perspectives/anaerobic-digestion-vs-gasification-navigating-the-future-of-energy-technologies#:~:text=Anaerobic%20digestion%20is%20a%20biological%20process%20producing%20biogas%20and%20digestate,raw%20material%20for%20producing%20chemicals.

Themes, E. (2021, March 22). What are siloxanes?. Interra Global. https://www.interraglobal.com/what-are-siloxanes/

Werkneh, A. A. (2022, October 6). Biogas impurities: Environmental and health implications, Removal Technologies and future perspectives. Heliyon. https://pmc.ncbi.nlm.nih.gov/articles/PMC9589174/#:~:text=Hence%2C%20biogas%20protects%20the%20environment,et%20al.%2C%202016).

What is a digester?. What Is a Digester? | U.S. Dairy. (n.d.). https://www.usdairy.com/news-articles/what-is-a-digester

What is biogas?. National Grid Group. (n.d.). https://www.nationalgrid.com/stories/energy-explained/what-is-biogas

What is biomass? definition, advantages, and types. REPSOL. (2023, September 11). https://www.repsol.com/en/energy-and-the-future/sustainable-mobility/biomass/index.cshtml#:~:text=Biomass%20is%20a%20heterogeneous%20energy,in%20the%20form%20of%20rubbish.

What is gas flaring?. World Bank. (n.d.). https://www.worldbank.org/en/programs/gasflaringreduction/gas-flaring-explained#:~:text=Flaring%20and%20venting%20are%20a,whole%20of%20sub%2DSaharan%20Africa.

Wikimedia Foundation. (2021, August 3). Gate fee. Wikipedia. https://en.wikipedia.org/wiki/Gate_fee#:~:text=A%20 gate%20 fee%20.

The world counts. (n.d.). https://www.theworldcounts.com/challenges/people-and-poverty/hunger-and-obesity/food-waste-statistics

YouTube. (n.d.-a). YouTube. https://www.youtube.com/watch?v=y-Gmjs20Xmc

YouTube. (n.d.-b). YouTube. https://www.youtube.com/watch?v=1PDjVDIrFec

Acknowledgement

I would like to acknowledge all of the people who helped me through the amazing journey of completing this project. These people include my teachers, parents, friends, as well as many other well-wishers who supported and enecouraged me through all of this. My parents played a role beacuse they motivated me through the issues that sprang up when completing this project. They also helped me in making my project more presentable and they gave me suggestions on how to make it better. My teachers were also an eternal help in this project as they were the people who stepped me through this path step by step and motivated to pursue my dream of CYSF. My friends were also an endless shower of support and provided the relaxation I often needed when I got to stressed out over menial things. They were a distraction for the bettter. All of these people have helped me come a long way with their ideas, perservering attitude, as well as their belief in me. I would like to thank all of them with gratitude.